Method for processing anti-stab coating of machine woven fabric

A technology of coating treatment and woven fabric, applied in the field of protective clothing, can solve the problems of hindering the flexibility of movement, increasing the load of the wearer, etc., to achieve the effects of light weight, improved stab resistance, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

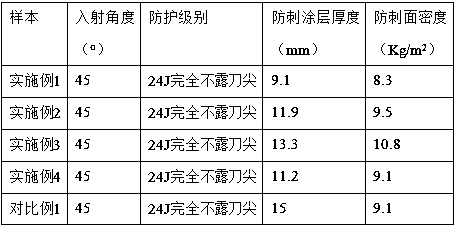

Examples

Embodiment 1

[0023] A method for treating a puncture-resistant coating of a woven fabric, comprising the following steps:

[0024] (1) Preparation of the first coating: put epoxy resin and polyamide in acetone at a mass ratio of 2:1, stir evenly with an ultrasonic stirrer, then add silicon carbide nanopowder with a mass percentage of 5% and The coupling agent with a mass percentage of 0.1% was stirred evenly with an ultrasonic stirrer again to obtain the first coating.

[0025] (2) Preparation of the second coating: put epoxy resin and polyamide in acetone at a mass ratio of 2:1, stir evenly with an ultrasonic stirrer, and then add nano-copper powder with a mass percentage of 5% and mass The coupling agent with a percentage content of 0.1% was stirred evenly with an ultrasonic stirrer again to obtain the second coating.

[0026] (3) Coating treatment: Lay the woven fabric flat, spray the first coating evenly on one side of the base fabric, and then spray the second coating on this basis, ...

Embodiment 2

[0028] A method for treating a puncture-resistant coating of a woven fabric, comprising the following steps:

[0029] (1) Preparation of the first coating: put epoxy resin and polyamide in acetone at a mass ratio of 2:1, stir evenly with an ultrasonic stirrer, then add silicon carbide nanopowder with a mass percentage of 5% and The coupling agent with a mass percentage of 0.1% was stirred evenly with an ultrasonic stirrer again to obtain the first coating.

[0030] (2) Preparation of the second coating: put epoxy resin and polyamide in acetone at a mass ratio of 2:1, stir evenly with an ultrasonic stirrer, and then add nano-copper powder with a mass percentage of 5% and mass The coupling agent with a percentage content of 0.1% was stirred evenly with an ultrasonic stirrer again to obtain the second coating.

[0031] (3) Coating treatment: Lay the woven fabric flat, spray the first coating evenly on one side of the base fabric, and then spray the second coating on this basis, ...

Embodiment 3

[0033] A method for treating a puncture-resistant coating of a woven fabric, comprising the following steps:

[0034] (1) Preparation of the first coating: put epoxy resin and polyamide in acetone at a mass ratio of 2:1, stir evenly with an ultrasonic stirrer, then add silicon carbide nanopowder with a mass percentage of 5% and The coupling agent with a mass percentage of 0.1% was stirred evenly with an ultrasonic stirrer again to obtain the first coating.

[0035] (2) Preparation of the second coating: put epoxy resin and polyamide in acetone at a mass ratio of 2:1, stir evenly with an ultrasonic stirrer, and then add nano-copper powder with a mass percentage of 5% and mass The coupling agent with a percentage content of 0.1% was stirred evenly with an ultrasonic stirrer again to obtain the second coating.

[0036] (3) Coating treatment: Lay the woven fabric flat, spray the first coating evenly on one side of the base fabric, and then spray the second coating on this basis, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com