Anti-cutting socks and manufacturing method thereof

A cut-resistant and cut-resistant technology, used in socks, pantyhose, knitting, etc., can solve the problem of no cut-resistant performance, and achieve good flexibility and comfort, improved strength, and good cut-resistant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

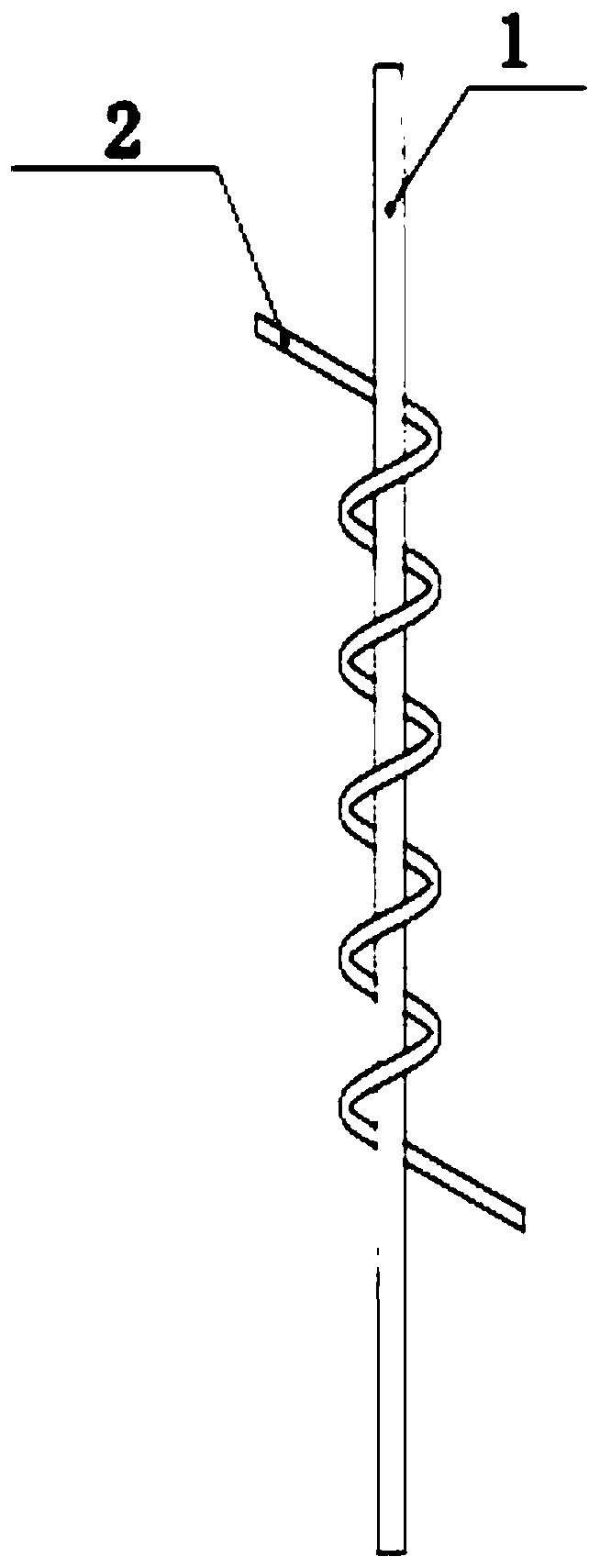

[0020] This embodiment provides a cut-resistant sock, which is woven from yarns, and the yarns include cut-resistant yarns; figure 1 As shown, the cut-resistant yarn is mainly composed of a core material 1 and a covering yarn 2 coated outside the core material 1, the core material 1 is an inorganic fiber or a metal wire, and the covering yarn 2 is an organic fiber .

[0021] Further, the inorganic fibers may be fibers made of hard materials such as glass fibers, quartz fibers, ceramic fibers or basalt fibers.

[0022] Further, the metal wire can be metal or alloy wire such as stainless steel wire, nickel alloy wire, titanium alloy wire, manganese alloy wire or tungsten alloy wire.

[0023] Further, organic fibers such as aramid fibers, ultra-high molecular weight polyethylene fibers, PBO fibers, PBI fibers, polyester fibers, high-strength nylon fibers, linear polyethylene fibers, and polysulfide fibers can be used as organic fibers.

[0024] Further, the knitting structure o...

Embodiment 2

[0026] This embodiment provides a method for making the anti-cut socks as described in Embodiment 1, specifically:

[0027] S1. Making cut-resistant yarn: use stainless steel wire with a diameter of 0.02mm as the core material, 400D ultra-high molecular weight polyethylene fiber as the covering material, and the twist is 400 turns / 10cm;

[0028] S2. Using the cut-resistant yarn produced in step S1, knitting to obtain cut-resistant cloth, cutting the cut-resistant cloth according to the template, and then sewing the sample according to the prescribed process to make cut-resistant socks.

[0029] The cut-resistant socks produced in this embodiment have a cutting resistance of 3 grades, a wear resistance of 3 grades, a tear resistance of 3 grades, and a puncture resistance of 3 grades.

Embodiment 3

[0031] This embodiment provides a method for making anti-cut socks as described in Embodiment 1, specifically:

[0032] S1. Making cut-resistant yarn: use 72tex glass fiber as the core material, 200D ultra-high molecular weight polyethylene fiber as the covering material, and the twist is 400 turns / 10cm;

[0033] S2. Using the cut-resistant yarn produced in step S1, the cut-resistant socks are obtained by knitting on a knitting machine.

[0034] The cut-resistant socks woven in this embodiment have a cut resistance of 4 grades, a wear resistance of 4 grades, a tear resistance of 3 grades, and a puncture resistance of 3 grades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com