Tire retreading method

A tire retreading and tire technology, which is applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of resource waste of waste tires, high tire blowout rate, life-threatening and other problems, so as to reduce the blowout rate and achieve good balance , the effect of increasing the strength of the carcass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

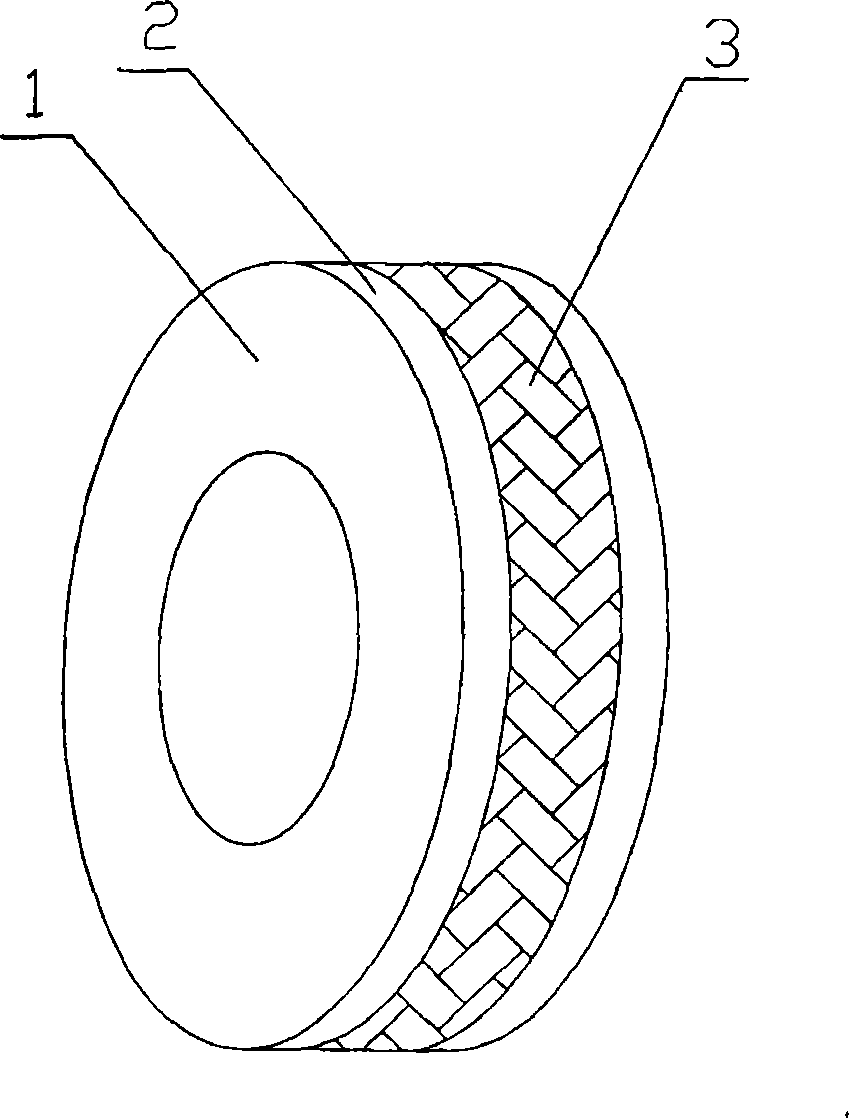

[0030] as attached figure 1 Shown, a kind of novel steel wire tire retreading method comprises the steps:

[0031] Step 1. The surface of the carcass 1 is ground, and the dirty tread is removed by grinding the steel wire tire, so that the surface is threaded and rough;

[0032] Step one includes:

[0033] Step 1.1 Grinding the surface of the carcass, grinding the tire crown to a certain size to remove the stained tread.

[0034] Step 1.2 Grinding: Grinding the punctures, punctures and rust on the 2 parts of the ground tire crown to remove the rust.

[0035] Step 2 sizing, brushing the mixture of glue and FRP resin on the tire surface;

[0036] Step 3 Wrap the brand-new rubber-coated steel wire cord fabric 3 on the tire crown, and attach the center rubber;

[0037] Step three includes:

[0038] Step 3.1 Divide: Divide the new rubber-coated steel cord fabric into widths of 1.3cm±0.3cm.

[0039] Step 3.2 Cleaning: Wash the divided new rubber-coated steel wire cord fabric wi...

Embodiment 2

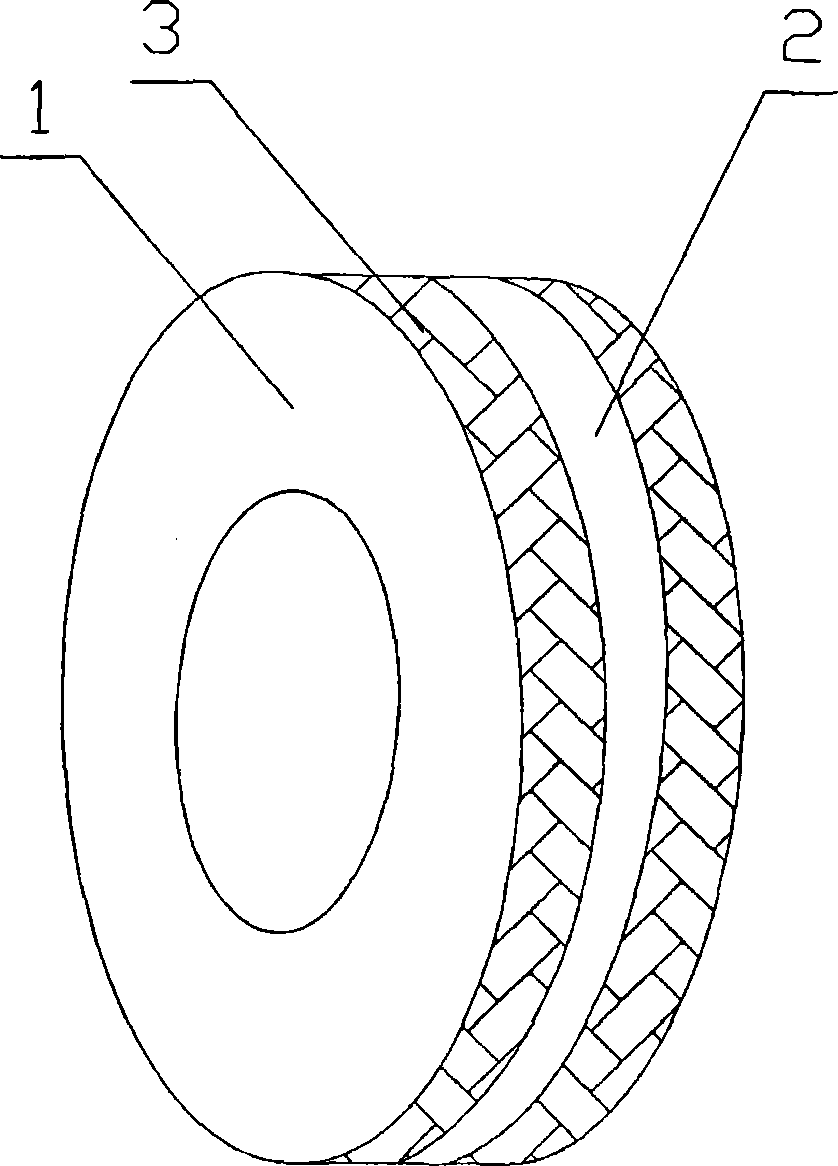

[0047] When the carcass has a lot of punctures, in step 3.3, use rubber-coated steel wire cord fabric 3 to wrap 8 to 10 times in the circumferential direction from 4 cm on both sides of the center line of the carcass to increase the strength of the crown. All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com