Puncture-proof fabric with porous buffer structure and preparation method of puncture-proof fabric

A buffer structure and fabric technology, applied in protective equipment, offensive equipment, other household appliances, etc., can solve the problems of absorbing stab-proof energy and contacting the position of the tip of the knife, and achieves enhanced stab-proof performance, reduced thickness, and excellent stab-proof. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

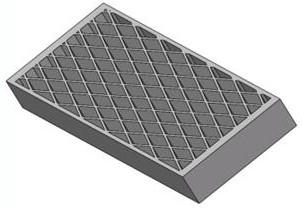

[0047]The preparation method of the stab-resistant fabric based on the present invention comprises the following steps:

[0048] Step S1: obtaining a porous buffer structure by 3D printing technology;

[0049] Step S2: obtaining the main stab-resistant structure through 3D printing technology, injection molding technology or hand lay-up technology;

[0050] Step S3: uniformly coat a layer of epoxy resin on the garment fabric, and neatly arrange the porous buffer structure in step S1 on the garment fabric;

[0051] Step S4: coating a layer of epoxy resin on the uniformly arranged porous buffer structure, and arranging the main body anti-stab structure in step S2 on the porous buffer structure as a whole;

[0052] Step S5 : pressing and curing the arranged integral stab-proof fabric on a flat-plate hot press to obtain a stab-proof fabric with a porous buffer structure.

[0053] The method for preparing the porous buffer structure by the 3D printing technology in step S1 of the...

Embodiment 1

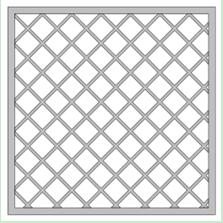

[0061] In this embodiment, the stab-proof fabric with porous buffer structure adopts aramid plain woven fabric as the base fabric, and the surface density is 200g / m 2 , the warp and weft density is 90×90 (root / 10cm), and the thickness is 0.26mm. The porous buffer structure in this embodiment is a square, and the main body anti-stab structure is consistent with the porous buffer structure. The material of the porous buffer structure is a polycarbonate wire with a wire diameter of 1.75mm. The main anti-stab material is carbon fiber composite material, the carbon fiber cloth is 3k plain weave cloth, and the surface density is 240g / m 2 , the resin is epoxy resin E44, curing agent polyamide resin 650. The preparation process of the stab-resistant fabric is as follows: (1) As attached figure 1 As shown, the top view of the porous buffer structure is a square with a side length of 25mm, in which the thickness of the outer shell is 1mm, the side length of the inner diamond-shaped v...

Embodiment 2

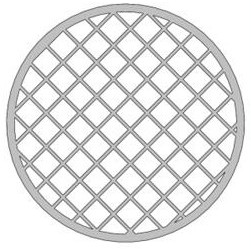

[0065] In this embodiment, the stab-proof fabric with porous buffer structure adopts polyester plain woven fabric as the base fabric, and the surface density is 200g / m 2 , the warp and weft density is 304×316 (root / 10cm). The porous buffer structure in this embodiment is circular, and the main body anti-stab structure is consistent with the porous buffer structure. The material of the porous buffer structure is a polycarbonate wire with a wire diameter of 1.75mm. The main body anti-stab material is polycarbonate. The preparation process of the stab-resistant fabric is as follows: (1) As attached figure 2 As shown, the top view of the porous buffer structure is a circle with a diameter of 30mm, the thickness of the outer shell is 1mm, the side length of the inner diamond-shaped void is 2.59mm, the distance between the diamonds is 0.4mm, and the angle of the diamonds in the thickness direction is vertical Downward, the thickness of the porous buffer structure is 2 mm. The 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com