Steel wire structured anti-burst tyre

A motorcycle tire and steel wire technology, applied in motorcycle tires, motorcycles, tire parts, etc., can solve the problems of weak tire load capacity, carcass and rim damage, imperviousness to puncture, etc., and achieve the improvement of stab resistance , The effect of small tire deformation and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

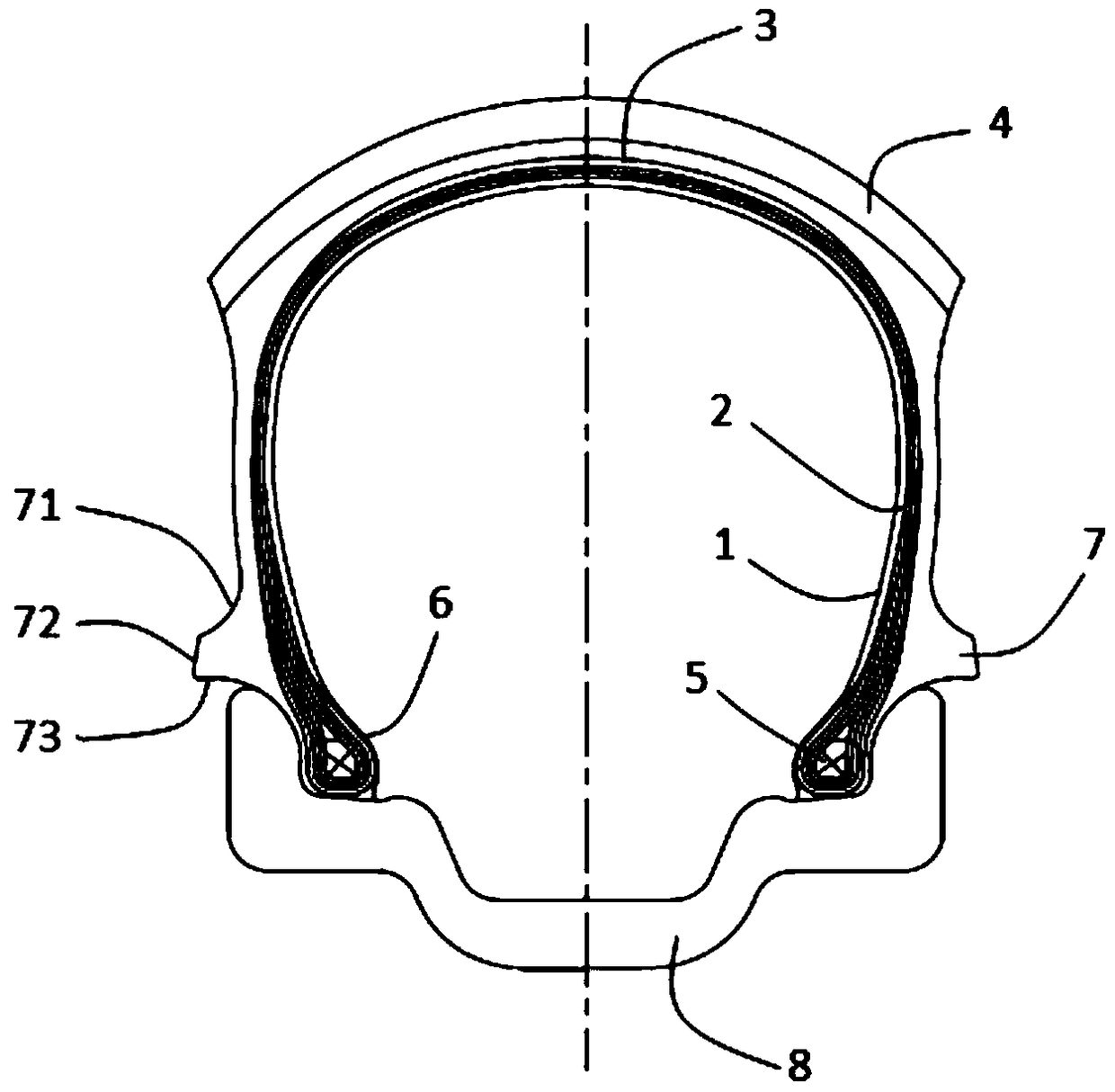

[0027] like figure 1 As shown, the explosion-proof motorcycle tire with steel wire structure includes an inner surface layer 1, a reinforcement layer 2, a steel wire ring belt buffer layer 3 and a tread layer 4 arranged sequentially from the inside to the outside, wherein: the inner surface layer 1 and the reinforcement layer 2 are sequentially arranged One circle is formed around, and the reinforcement layer 2 is arranged on the outer periphery of the inner surface layer 1 , the steel wire hoop buffer layer 3 is arranged on the outer periphery of the reinforcement layer 2 , and the tread layer 4 is arranged on the outer periphery of the steel wire hoop buffer layer 3 .

[0028] like figure 1 As shown, the reinforcing layer 2 is a nylon bias cord layer, and the nylon bias cord layer is two overlapping layers, and the reinforcing layer 2 wraps around the bead ring 5 and extends to the bead roll. This setting ensures that the carcass And the wear resistance of the sidewall is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com