Adhesive used for preparing stab-resistant fabrics

An adhesive and solvent technology, applied in the directions of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of poor creep performance of adhesives, no flame retardancy, and stab-resistant fabrics that are flammable in case of fire. Creep resistance, flame retardancy, improved adhesive strength, and wider application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

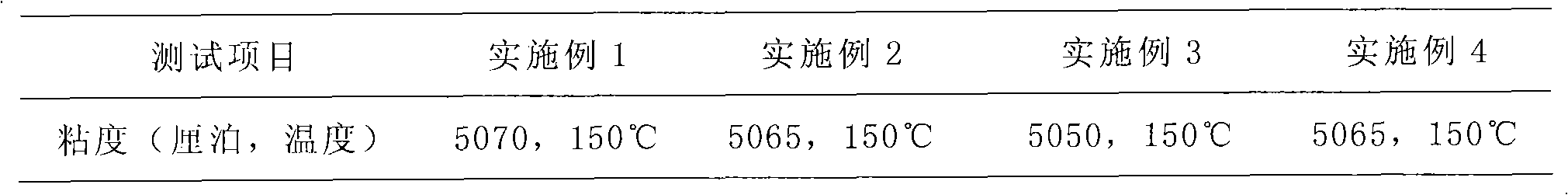

Embodiment 1

[0039] 1. Provide adhesive raw materials with the following ingredients:

[0040] KARTON D-1107 8.2wt%;

[0041] Rosin glyceride 2.2wt%;

[0042] Epoxidized soybean oil 0.91wt%;

[0043] Halogen-free flame retardant 2.3wt%;

[0044] Antioxidant 0.8wt%;

[0045] No. 120 solvent naphtha (2,3-butanedione) balance.

[0046] 2. Preparation of adhesive: Add KARTON D-1107, antioxidant and 20wt% No. 120 solvent oil into the mixer that has been preheated to 185°C, mix well and lower the temperature to 160°C, and then add them to the mixer in turn Halogen-free flame retardant, epoxidized soybean oil, rosin glyceride and the balance of No. 120 solvent oil were mixed for 25 minutes and then the mixing process was stopped to obtain an adhesive.

Embodiment 2

[0048] 1. Provide adhesive raw materials with the following ingredients:

[0049] KARTON G-1650 8.1wt%;

[0050] Rosin 2.5wt%;

[0051] Epoxidized soybean oil 0.90wt%;

[0052] Halogen-free flame retardant 2.1wt%;

[0053] No. 120 solvent naphtha balance.

[0054] 2. Preparation of adhesive: Add KARTON G-1650 and 20wt% No. 120 solvent oil into the mixer that has been preheated to 185°C, mix well and lower the temperature to 157°C, then add halogen-free flame retardant into the mixer in turn Agent, epoxidized soybean oil, rosin and the balance of No. 120 mineral spirits were mixed for 30 minutes and then the mixing process was stopped to obtain an adhesive.

Embodiment 3

[0056] 1. Adhesive raw materials with the following components are provided, and the HIPSPH-88E is provided by Taiwan Chi Mei Industrial Co., Ltd.:

[0057] HIPS PH-88E 5.1wt%;

[0058] Rosin 1.2wt%;

[0059] Epoxidized soybean oil 0.53wt%;

[0060] Halogen-free flame retardant 1.1wt%;

[0061] No. 120 solvent naphtha balance.

[0062] 2. Preparation of adhesive: Add HIPS PH-88E and 20wt% No. 120 solvent oil into the mixer that has been preheated to 180°C, mix well and lower the temperature to 150°C, then add halogen-free flame retardant into the mixer in turn Agent, epoxidized soybean oil, rosin and the balance of No. 120 mineral spirits were mixed for 25 minutes and then the mixing and mixing process was stopped to obtain an adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com