Tackifying and reinforcing modified polysiloxane and preparation method and application thereof

A technology of polysiloxane and methyl vinyl polysiloxane, which is applied in the field of modified polysiloxane for tackifying and reinforcing and its preparation, can solve the problem of surface stickiness, insufficient adhesion of packaging materials, LED The problems such as the decrease of the light transmittance of the glue, to achieve the effect of improving the bonding strength, good light transmittance and tensile strength, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

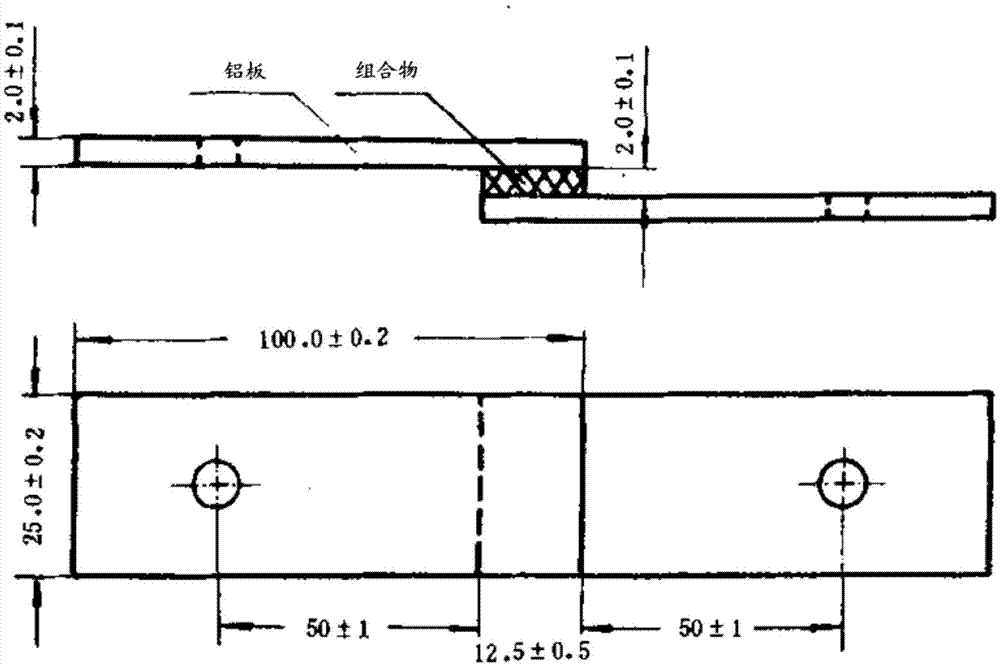

Image

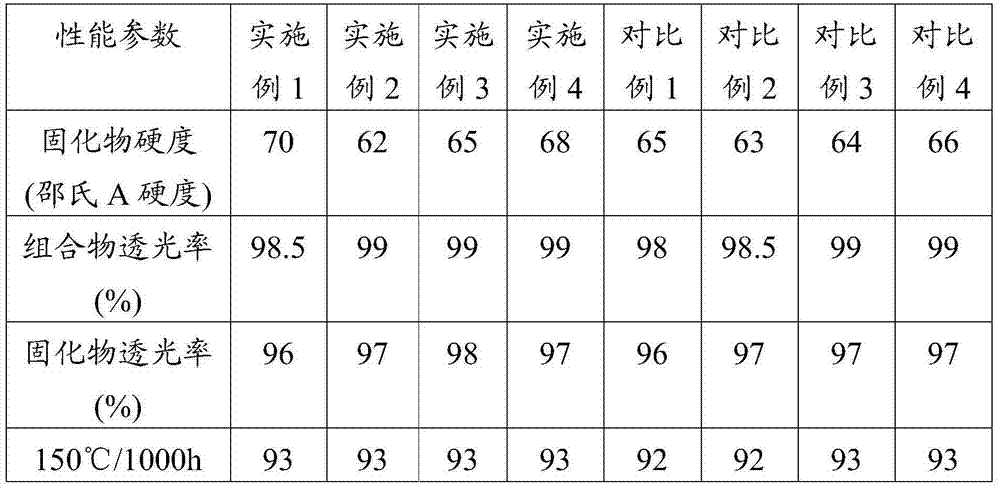

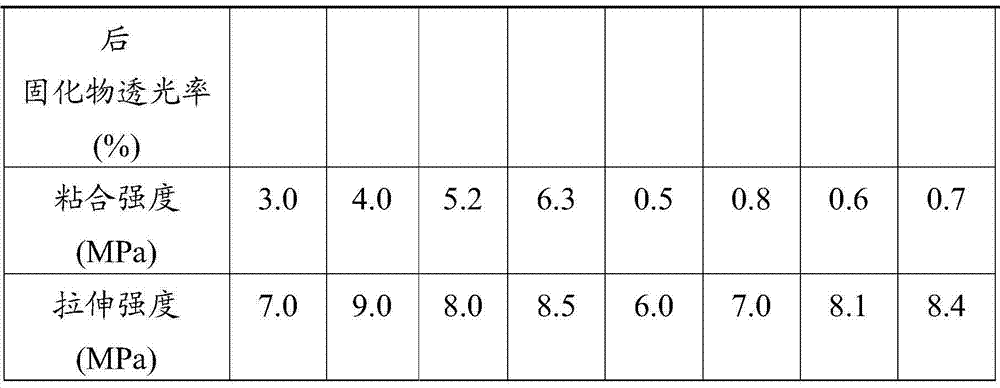

Examples

Embodiment 1

[0102]To 100 parts by mass of methyl vinyl polysiloxane, add 60 parts by mass of toluene and 2 parts by mass of tetramethyldisiloxane, after the methyl vinyl polysiloxane is dissolved, Heat up to 80°C, add 0.05 parts by mass of p-toluenesulfonic acid, stop heating and stirring after 8 hours to obtain a toluene solution of the intermediate polysiloxane product, cool to room temperature, and wash with deionized water 3 times to medium properties, put anhydrous calcium chloride into the solution of the intermediate polysiloxane product to remove the moisture in the solution. After the solution is clarified, anhydrous calcium chloride is filtered off, 100 parts by mass of toluene is added, and the intermediate polysiloxane product solution is slowly added dropwise to 7 parts of allyl glycidyl ether, 8 parts of vinyl In the mixed solution of trimethoxysilane and 0.04 parts by mass of chloroplatinic acid isopropanol solution (Pt content is 8000ppm), after reacting for 6 hours, the t...

Embodiment 2

[0105] To 100 parts by mass of methyl vinyl polysiloxane, add 80 parts by mass of toluene and 5 parts by mass of tetramethyldisiloxane, after the methyl vinyl polysiloxane is dissolved, Raise the temperature to 85°C, and add 0.1 parts by mass of phosphazene chloride, stop heating and stirring after 6 hours to obtain a toluene solution of the intermediate polysiloxane product, cool to room temperature, wash with deionized water 5 times until neutral, Anhydrous calcium chloride is put into the solution of the intermediate polysiloxane product to remove moisture from the solution. After the solution is clarified, anhydrous calcium chloride is filtered off, 200 parts by mass of toluene is added, and the intermediate polysiloxane product solution is slowly added dropwise to 5 parts by mass of γ-methacryloxypropane at 50°C. In a mixed solution of trimethoxysilane, 10 parts by mass of vinyltriethoxysilane and 0.04 parts by mass of chloroplatinic acid tetramethyldivinyldisiloxane comp...

Embodiment 3

[0108] To 100 parts by mass of methyl vinyl polysiloxane, add 100 parts by mass of toluene and 3 parts by mass of tetramethyldisiloxane, after the methyl vinyl polysiloxane is dissolved, Raise the temperature to 90°C, and add 0.06 parts by mass of Super acid, stop heating and stirring after 2 hours to obtain the toluene solution of the intermediate polysiloxane product, cool to room temperature, wash with deionized water 4 times until neutral, put anhydrous calcium chloride into the intermediate polysiloxane product solution to remove water from the solution. After the solution is clarified, anhydrous calcium chloride is filtered off, 150 parts by mass of toluene is added, and the intermediate polysiloxane product solution is slowly added dropwise to 6 parts by mass of allyl glycidyl ether, 9 parts by mass of Parts of vinyltrimethoxysilane and 0.04 parts by mass of hydrosilylation catalyst (Pt content: 8000ppm) in the mixed solution, after 4 hours of reaction, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com