High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

A technology of ceramic cutting tools and base metals, which is applied in the field of high wear-resistant Ti-based cermet cutting tools and its preparation, can solve the problems of difficult to control uniform dispersion, high cost, and limited wide use, and achieve the goal of anti-oxidative wear and anti-diffusion wear Increased capacity, reduced cutting costs, and facilitated mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

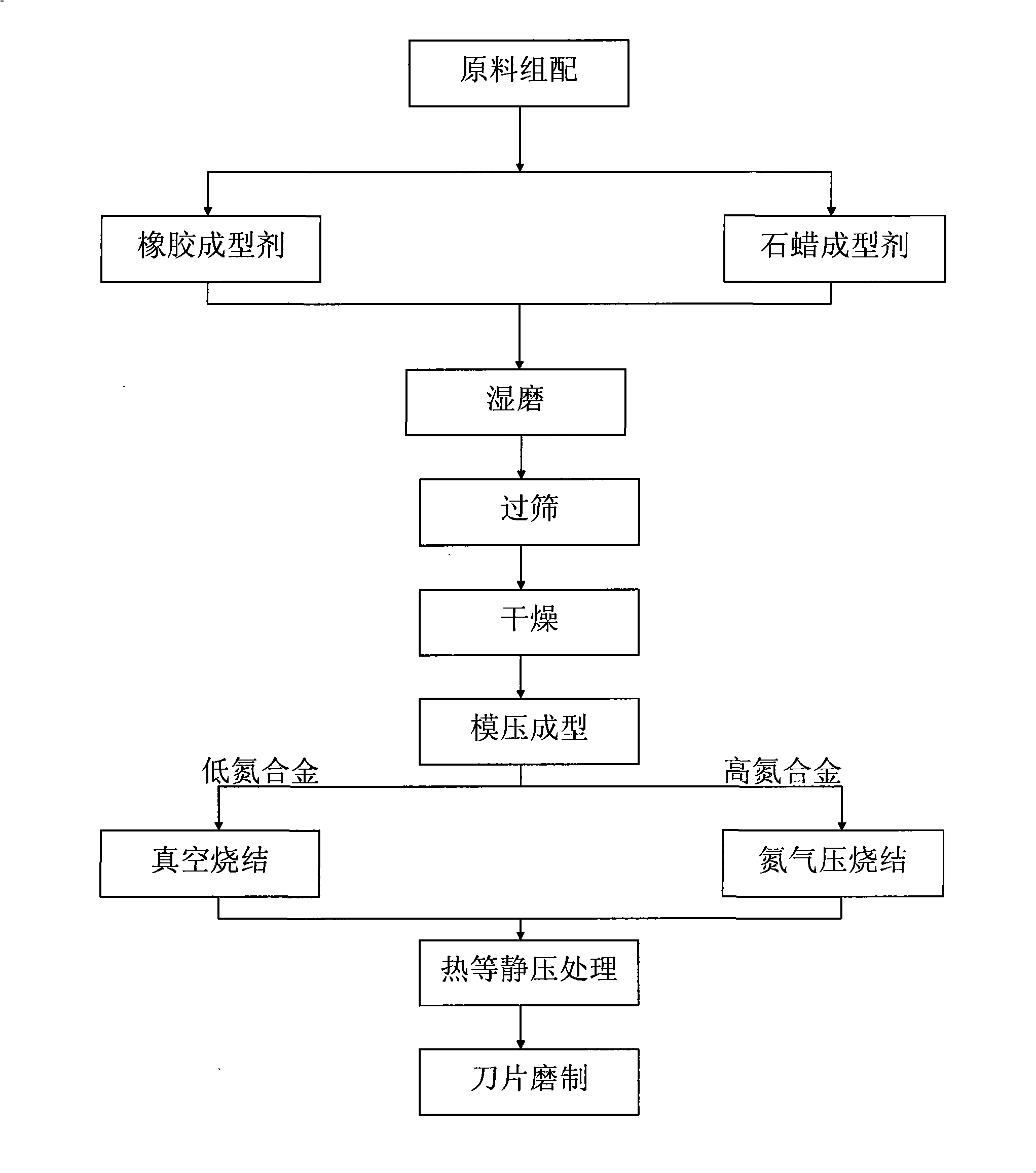

[0117] Sub-implementation mode (divided into high-nitrogen alloy preparation process and low-nitrogen alloy preparation process according to the amount of nitrogen content)

[0118] Referring to the accompanying drawings, it is prepared by powder metallurgy process, with Ni and Co as the binder phase, and adding Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x At least one carbonitride is a highly wear-resistant Ti(C,N)-based cermet tool with a basic coordination composition, wherein the X value of the carbonitride added is: 0.4≤X≤0.5 or 0.5<X≤0.7;

[0119] The preparation process is divided into high nitrogen alloy preparation process and low nitrogen alloy preparation process according to the nitrogen content:

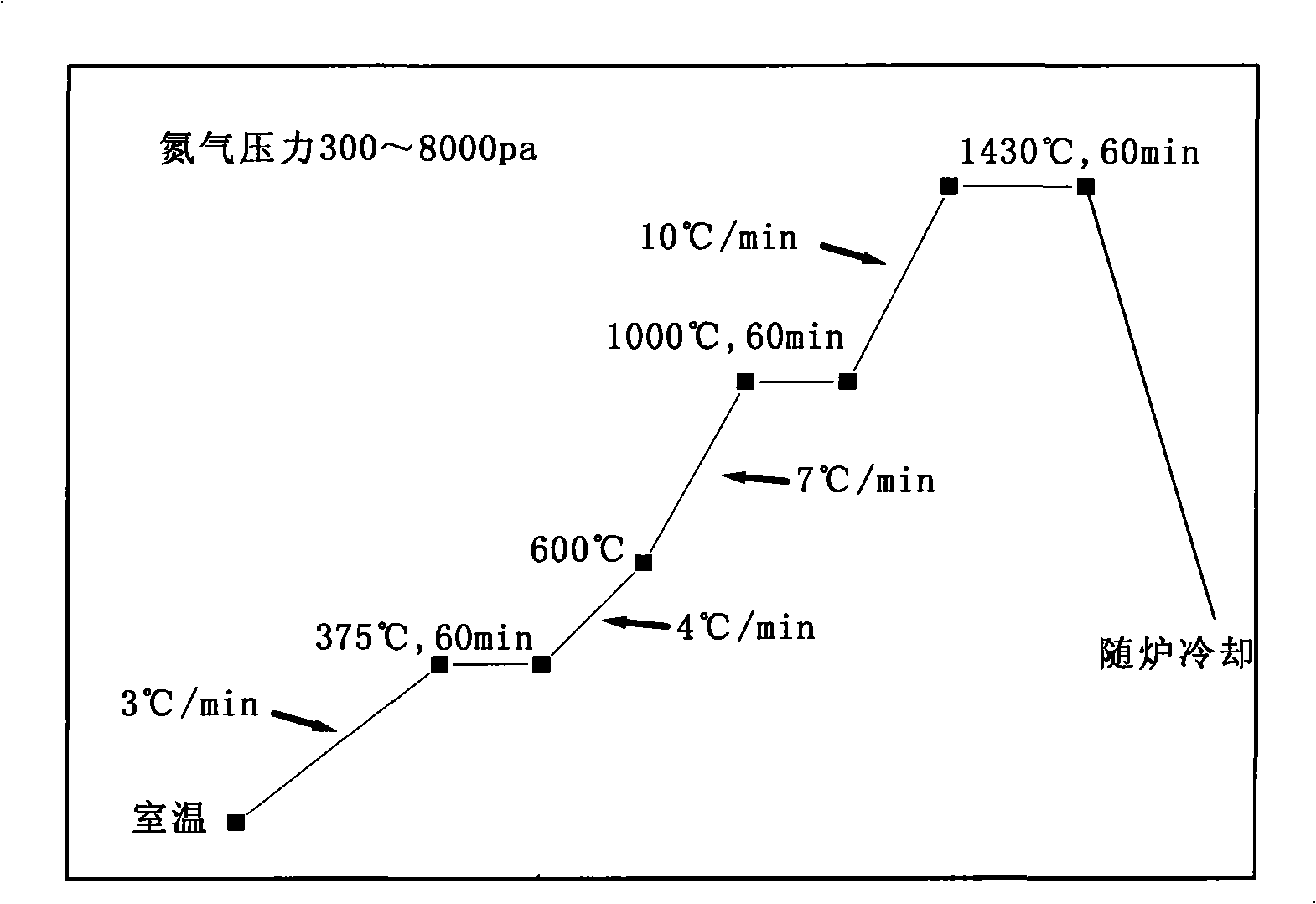

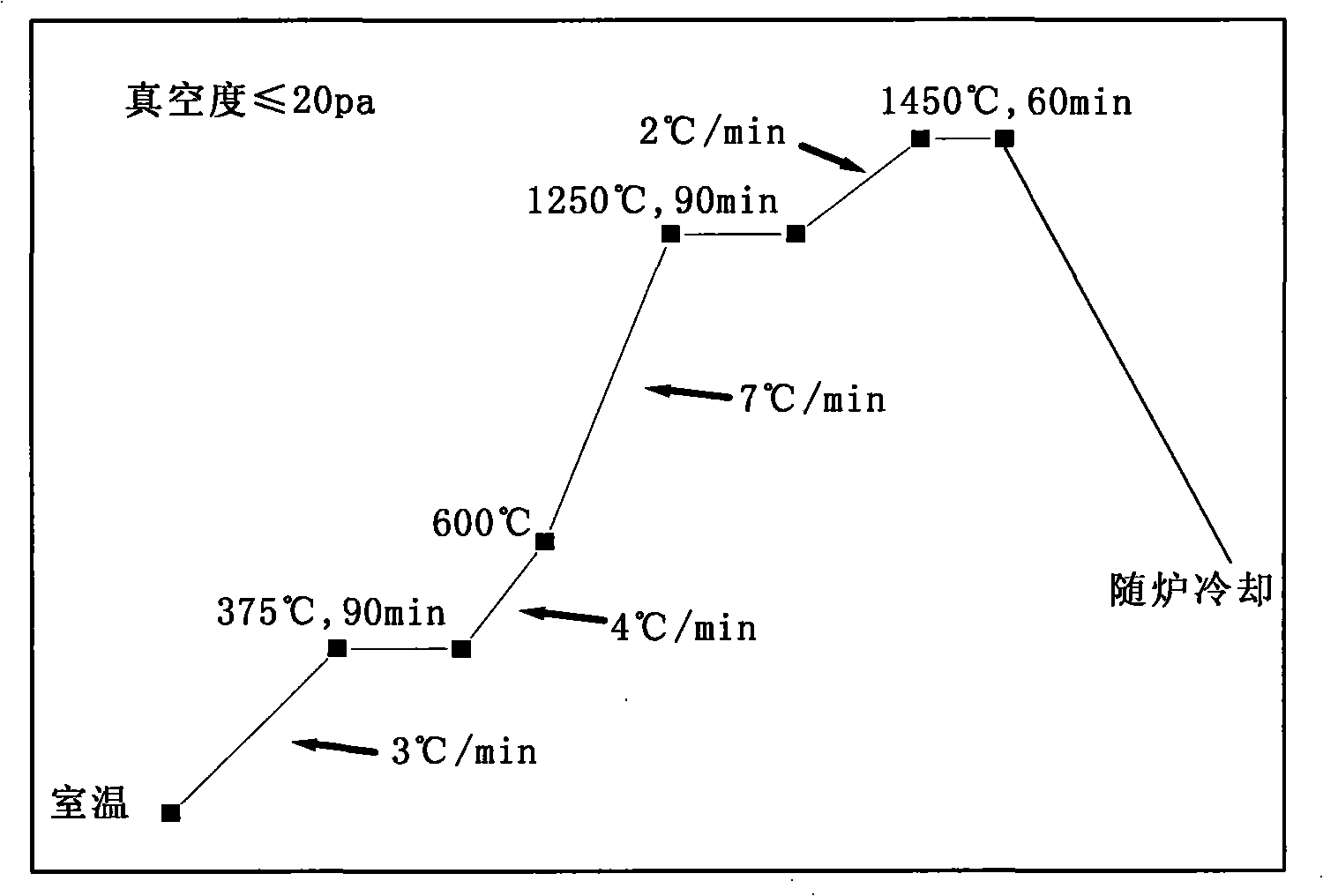

[0120] (a) When containing Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x When at least one carbonitride is the nitrogen content in the basic batch, the X value of the nitrogen content is 0.4≤X≤0.5 (X≤0.5) (called high-nitrogen alloy), and the nitrogen pressure sintering process ...

no. 1 approach 0

[0124] First Embodiment [0.50.5)]

[0125] For Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x In the base cermet, this embodiment is adopted when the X value of the nitrogen content of at least one carbonitride is 0.50.5).

[0126] In the present invention, the TiCN-based cermet cutting tool refers to a sintered body of compacted powder having the following basic composition. The basic composition of the compact contains at least:

[0127] WC 10~20wt%

[0128] Mo 2 C 5~15wt%

[0129] Co 5~15wt%

[0130] Ni 5~10wt%

[0131] ZrC 0.1~2wt%

[0132] Cr 3 C 2 0.1~2wt%

[0133] VC 0.1~2wt%

[0134] At the same time, the compressed powder should also contain at least one of the following compounds:

[0135] TaC 0.1~15wt%

[0136] NbC 0.1~15wt%

[0137] The margin is:

[0138] Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x Wherein, the value of nitrogen content X is: 0.50.5)

Embodiment approach 1

[0141] WC 10~20wt% TaC 5~15wt%

[0142] Mo 2 C 5~15wt% or (Mo 4.7~14.1wt%+C0.3~0.9wt%)

[0143] Co 5~15wt% Ni 5~10wt% ZrC 0.1~2wt%

[0144] Cr 3 C 2 0.1~2wt% VC 0.1~2wt%

[0145] Balance Ti(C x , N 1-x ) or (TiC) x +(TiN) 1-x Wherein, the value of nitrogen content X is: 0.50.5)

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com