Toroidal ring manifold for secondary fuel nozzle of a dln gas turbine

a gas turbine and secondary fuel technology, applied in the direction of machines/engines, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of incomplete effective mixing of fuel and air, elevated emissions of gas turbines, and inability to properly mix fuel and air, so as to promote the effect of reducing emissions and improving combustion dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

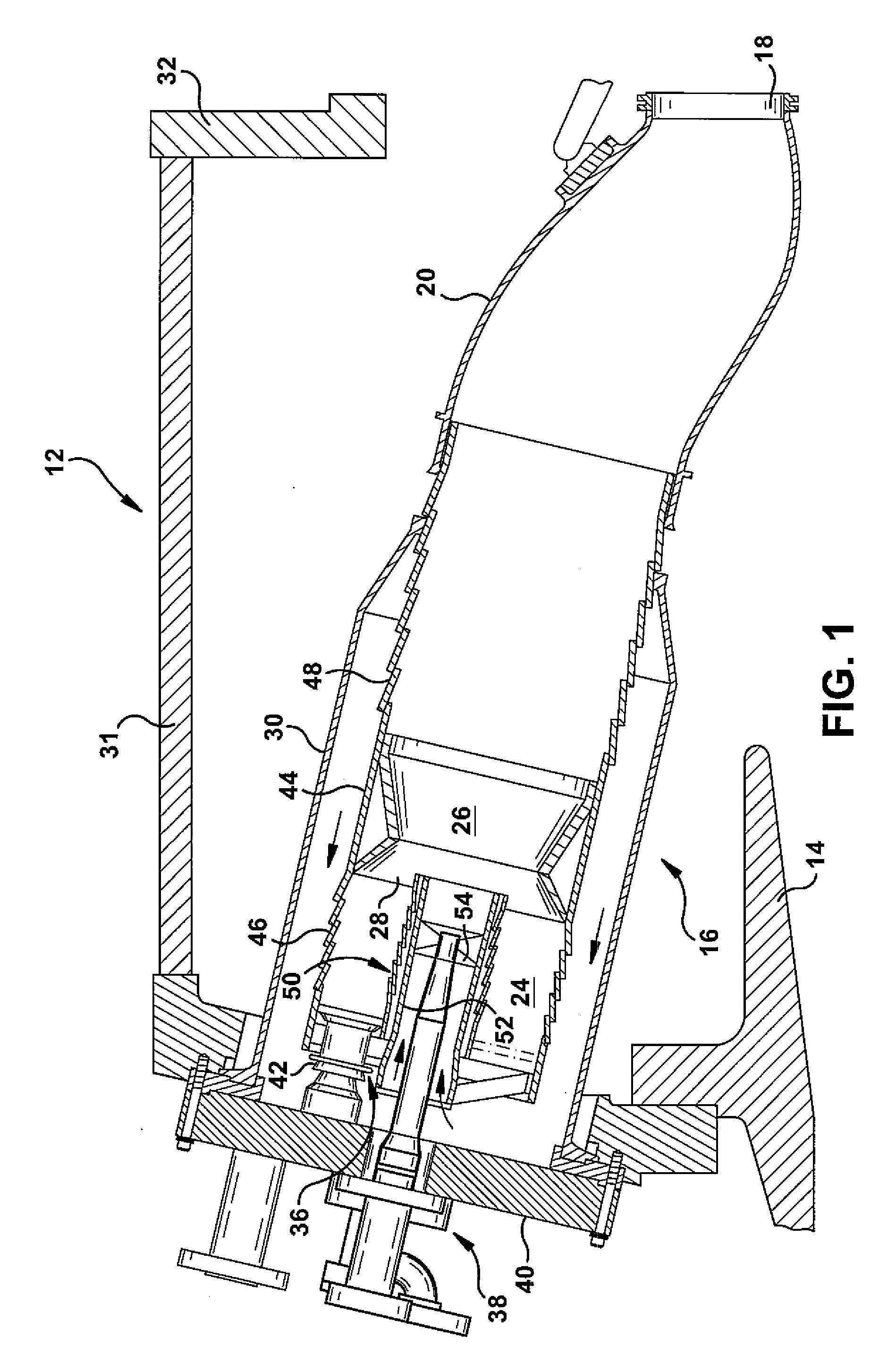

[0037]The following embodiments of the present invention have many advantages, including effectively dispersing premixing fuel with air in the secondary nozzle of a combustor for a Dry Low NOx (DLN) gas turbine, thereby providing stable combustion with low nitrogen oxide (NOx) emissions.

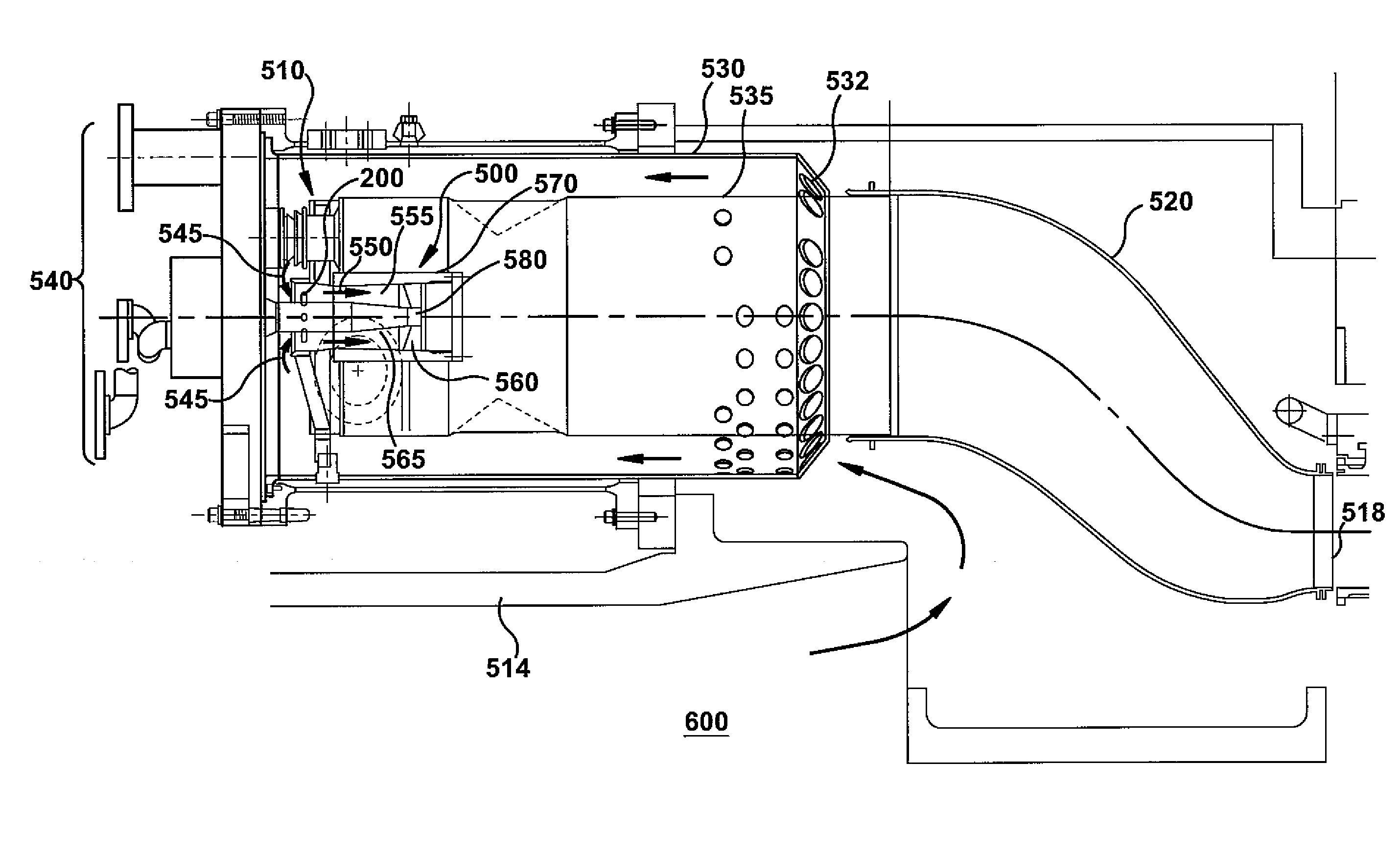

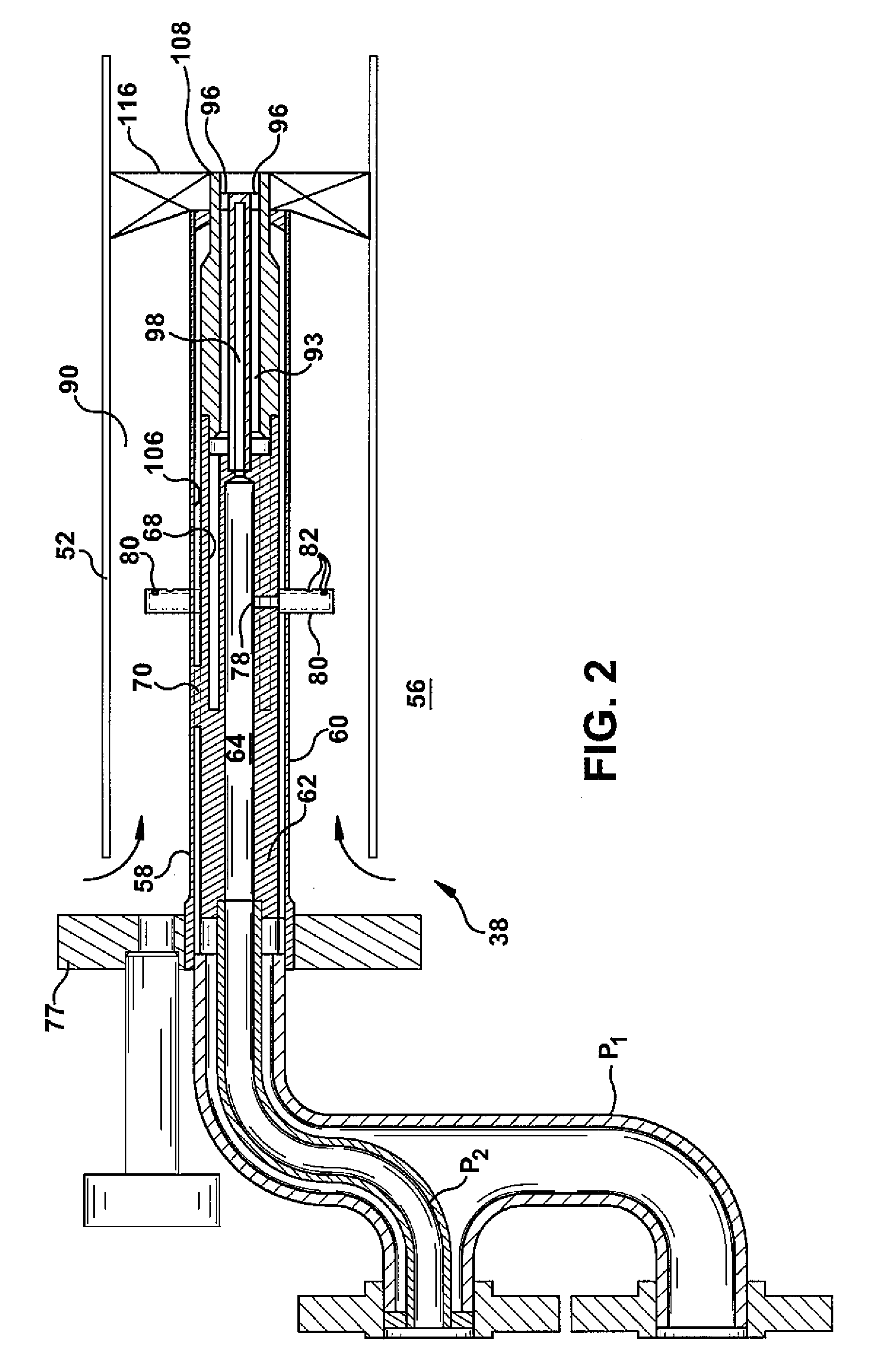

[0038]According to one aspect of the present invention a toroidal ring manifold is provided to disperse fuel into the premixing volume between a secondary nozzle body and the finer. FIG. 5A illustrates a cross-section of a toroidal shell. A toroidal ring manifold 200 may comprise a generally toroidal-shaped shell 210, with a circular ring cross section 215. The toroidal-shaped shell 210 is centered on a poloidal axis 220. When the toroidal ring manifold 200 is united with a nozzle body 400 (partially shown) as part of a secondary fuel assembly, the poloidal axis may be coincident with a longitudinal axis 305 of the nozzle body 400. A toroidal axis 225 runs through the center 230 of circular ring cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com