Saw frame feeding system with constant saw cutting force and variable feeding speed and saw frame feeding method

A technology of feed speed and feed system, which is applied in the direction of metal sawing equipment, sawing machine devices, manufacturing tools, etc., can solve the problem that the technological strength is not as good as that of others, and the saw frame feed control system does not consider the entry and exit work. , the lack of countermeasures and other problems, to achieve the effect of simple and effective control scheme, reducing saw blade consumption and perfect solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

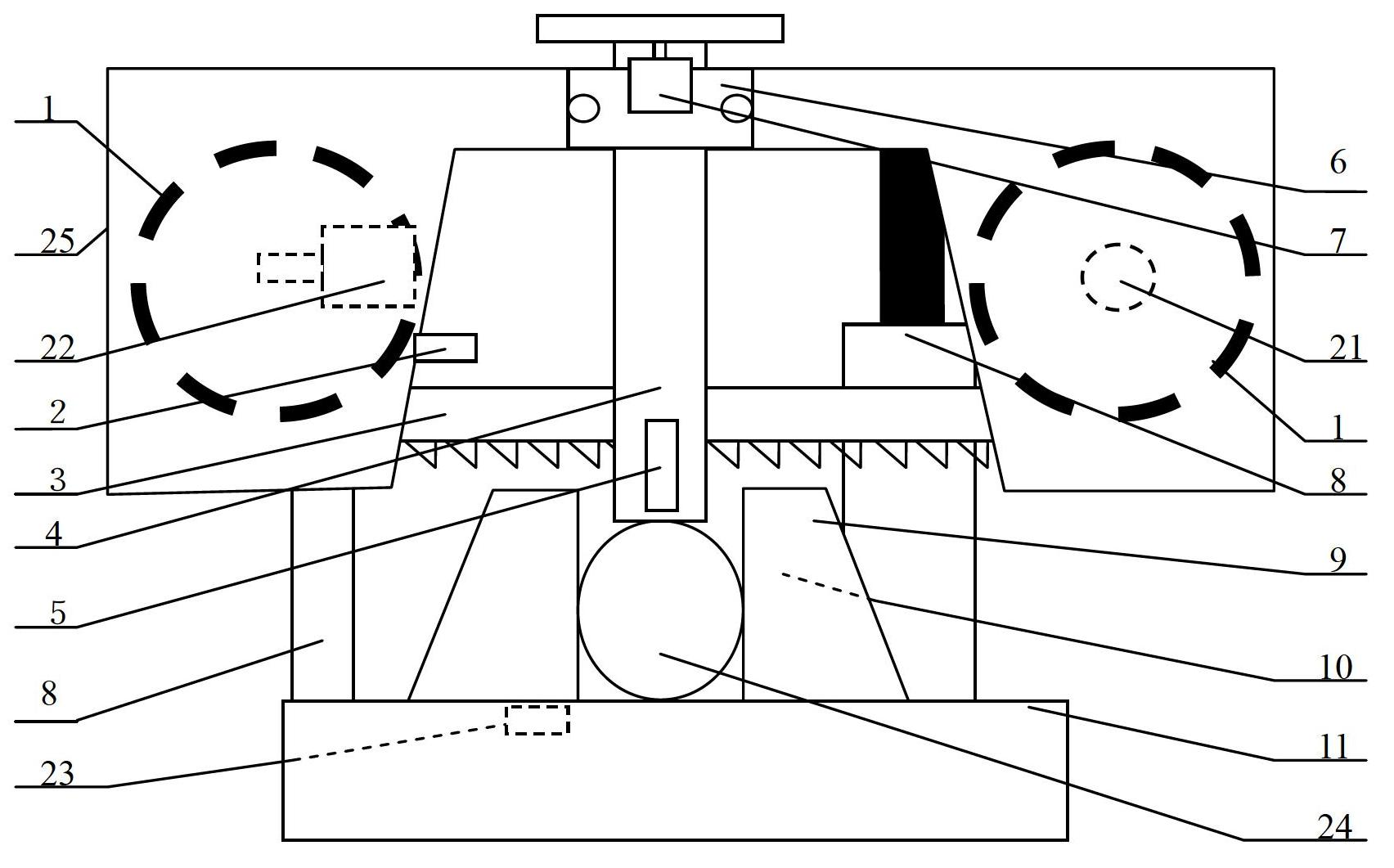

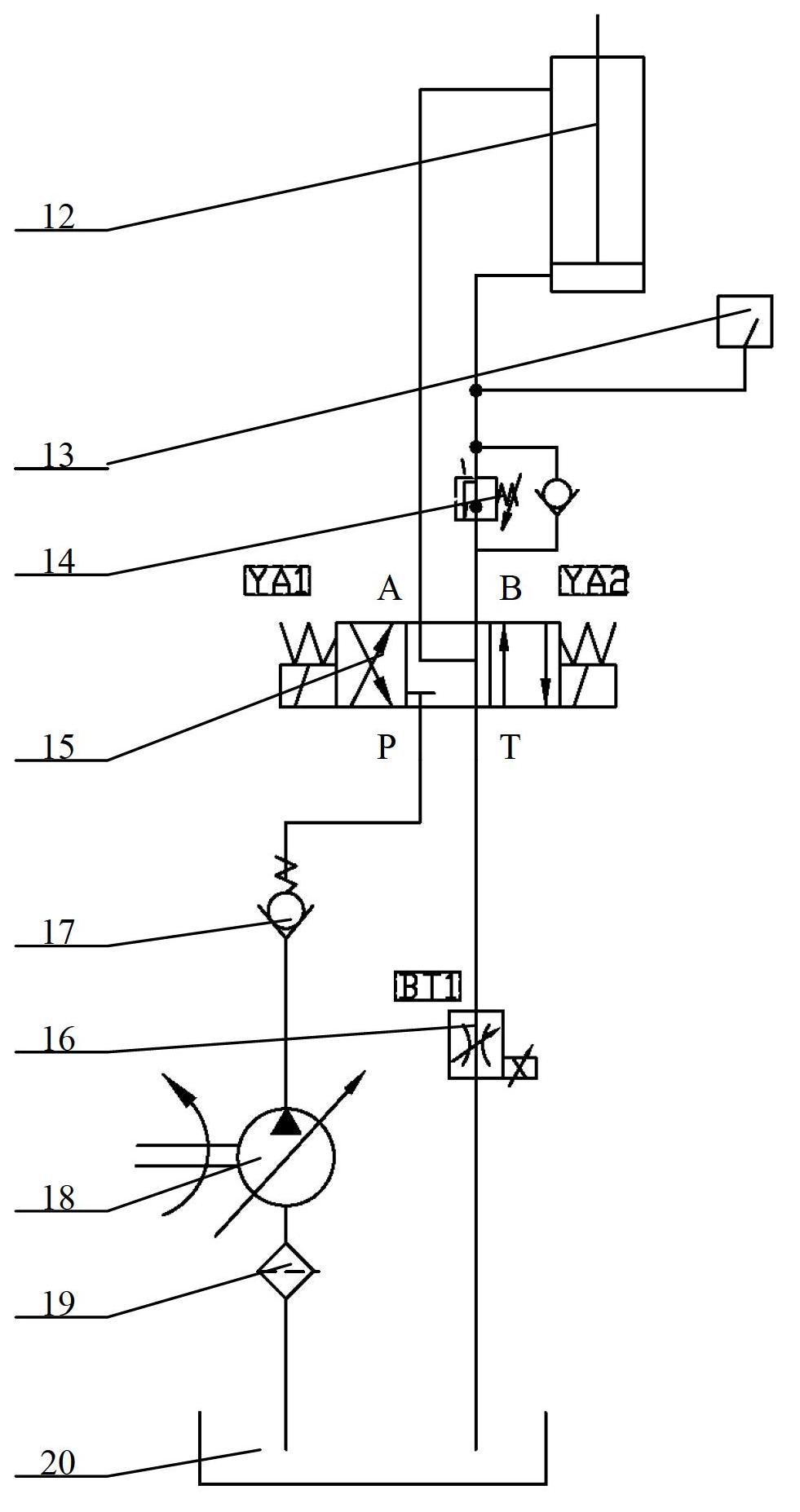

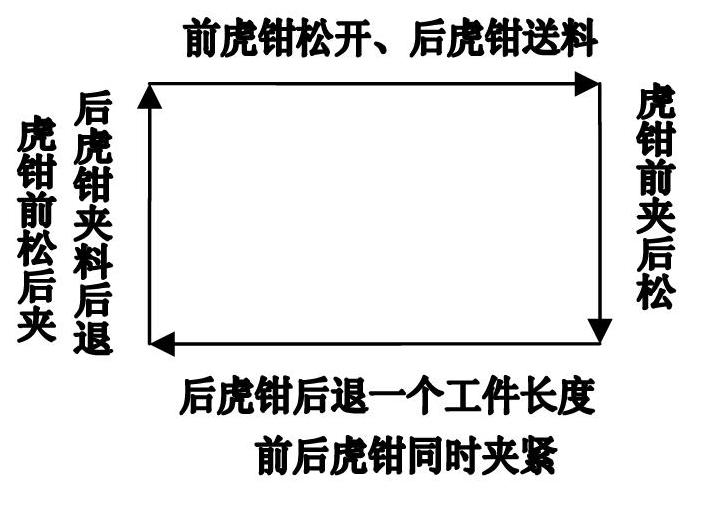

[0030] Such as figure 1 , 2 As shown, the saw frame feeding system with constant sawing force and variable feed speed includes saw frame, hydraulic system, and control system; the saw frame includes driving wheel 1, distance measuring sensor 2, saw blade 3, workpiece detection rod 4, Rich Hardness tester 5, guide rail 6, travel switch 7, saw frame fixed frame 25, driving wheel drive variable frequency motor 21, driven wheel tension oil cylinder 22 and grating ruler 23 used for feeding length detection; on the saw frame fixed frame 25 There are driving wheel 1, distance measuring sensor 2, Leeb hardness tester 5, guide rail 6, driving wheel drive variable frequency motor 21 and driven wheel tensioning oil cylinder 22, saw blade 3 is connected with driving wheel 1, driving wheel is connected with driving wheel The wheel drive frequency conversion motor 21 is connected, the driven wheel is connected with the driven wheel tensioning oil cylinder 22; the workpiece detection rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com