Forging process of golf club head in complex shape

A golf head and complex shape technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of complex shape of the golf head body, forging and direct forming of the groove of the ball head body, difficulty in making golf heads, etc. Achieve the effect of low technical requirements for workers, high yield rate, and changing material characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

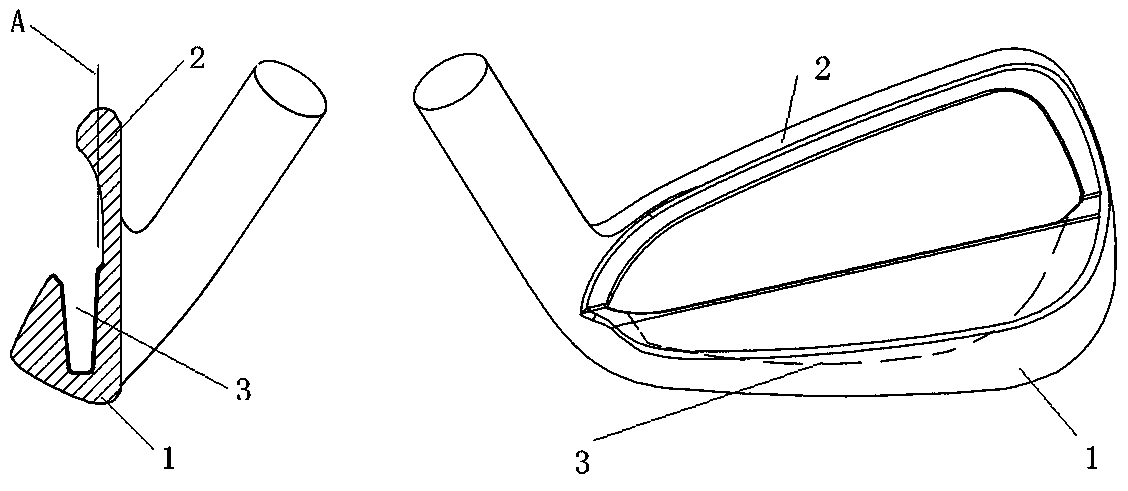

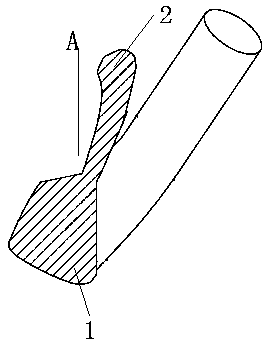

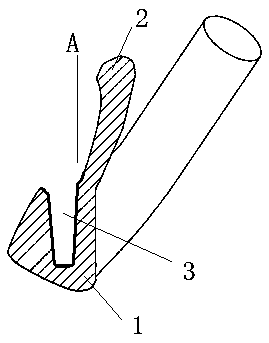

[0021] The forging process of complex-shaped golf heads, including the head body, striking face and weight.

[0022] In order to achieve a good hitting effect, the position of the center of gravity of the golf head is often customized by the user according to his own hitting habits. When designing a golf head, the middle part of the ball head body is designed as a hollow structure to reduce the weight of its shell, and the reduced weight is installed on the ball head body at a suitable position by means of counterweights, thereby changing the position of its center of gravity to meet the needs of users.

[0023] figure 1 Shown is a ball head body structure designed according to user needs. In order to change the center of gravity of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com