Bamboo-wood composite board with high-strength bamboo plywood coated on the surface and manufacturing method thereof

A bamboo-wood composite and plywood technology, applied in the field of composite panels, can solve problems such as decay, loose and uneven material, and variability, and achieve the effects of high surface finish and flatness, long continuous use time, and increased product added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

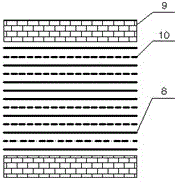

[0028] The structure of the bamboo-wood composite container floor covered with high-strength bamboo plywood is as follows: image 3

[0029] The manufacture method of the bamboo-wood composite container bottom plate covered with high-strength bamboo plywood is as follows:

[0030] a. Sorting and finishing of eucalyptus veneers, bamboo curtains, and bamboo mats. The moisture content of eucalyptus veneers is ≤8%. Add 10% flour, and add an appropriate amount of insecticide to the glue, the amount of glue is 250-380g / m 2 ,; and dry bamboo curtains and mats with different thicknesses to a moisture content below 12%, impregnated with phenolic glue and dry them at low temperature to a moisture content below 16% (bamboo curtain) and 20% (bamboo mat);

[0031] b. Assembling and hot pressing of bamboo plywood. Bamboo mats and curtains are assembled. The structure is that the top layer is a layer of bamboo mats, and the bottom is six layers of 1.2mm longitudinal bamboo curtains. The te...

Embodiment 2

[0040] The structure of the bamboo-wood composite truck compartment railing covered with high-strength bamboo plywood is as follows: Figure 4

[0041] The manufacturing method of the bamboo-wood composite truck compartment railing plate covered with high-strength bamboo plywood is as follows:

[0042]Sorting and finishing of fir veneers, bamboo curtains and bamboo mats. The moisture content of fir veneers is ≤12%. According to the requirements, fir veneers are coated with phenolic resin glue on both sides during secondary molding, and the amount of glue applied is 300g / m 2 ,; and dry bamboo curtains and mats with different thicknesses to a moisture content below 12%, impregnated with phenolic glue and dry them at low temperature to a moisture content below 16% (bamboo curtain) and 20% (bamboo mat);

[0043] b. Assembling and hot pressing of bamboo plywood. Bamboo mats and curtains are assembled. The structure is that the top layer is a layer of bamboo mat, and the bottom is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com