Flame-retardant veneer laminated fireproof door frame and manufacturing method

A technology of laminated veneer lumber and fire doors, applied in fire doors, window/door frames, sealing devices, etc., can solve the problems of difficult flame retardant treatment, poor flame retardant effect and high cost of solid wood, and achieve the protection of natural forests. The effect of resources, good flame retardant performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

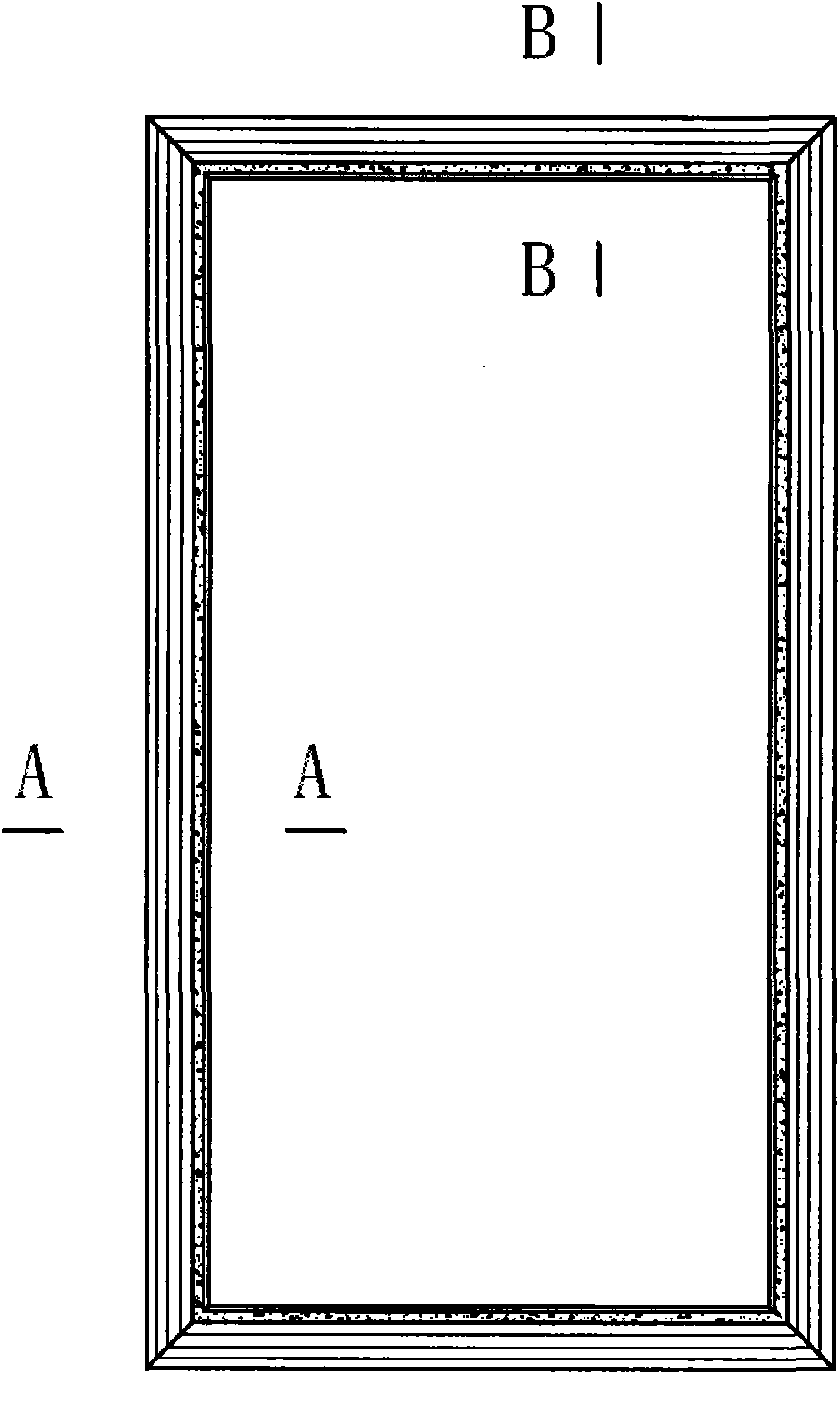

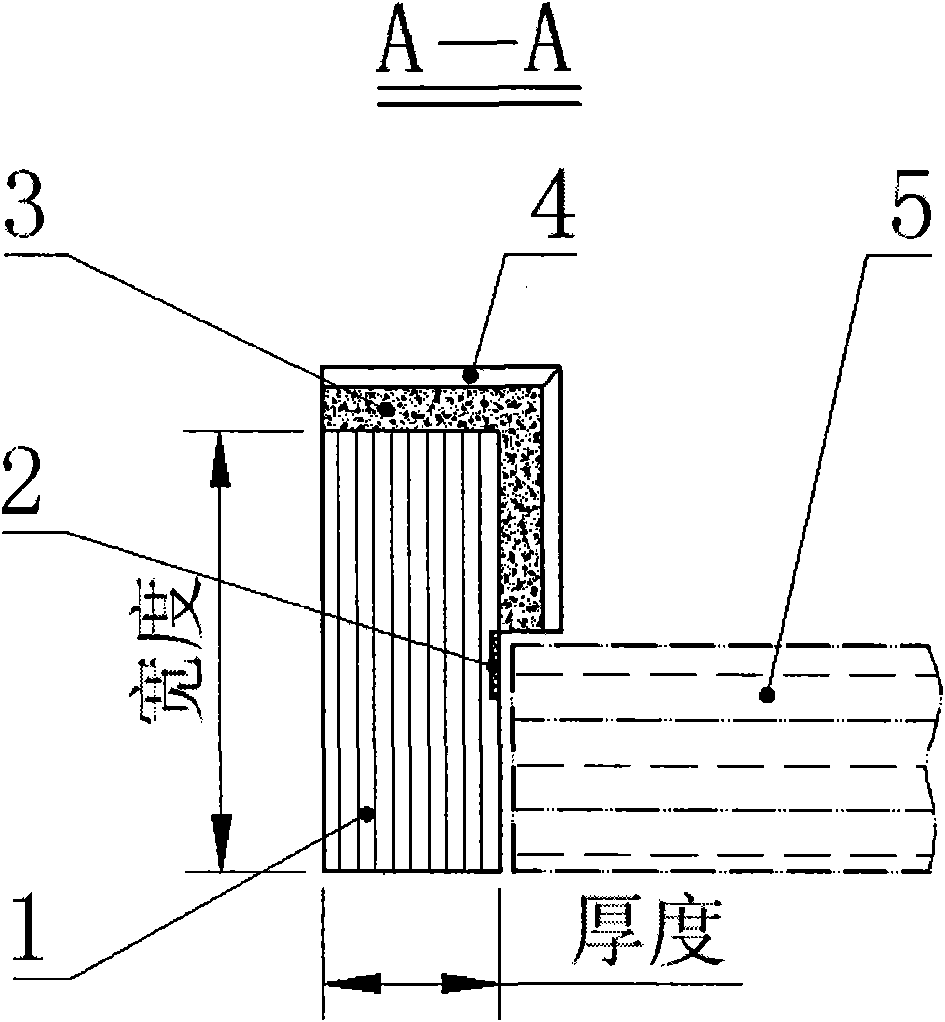

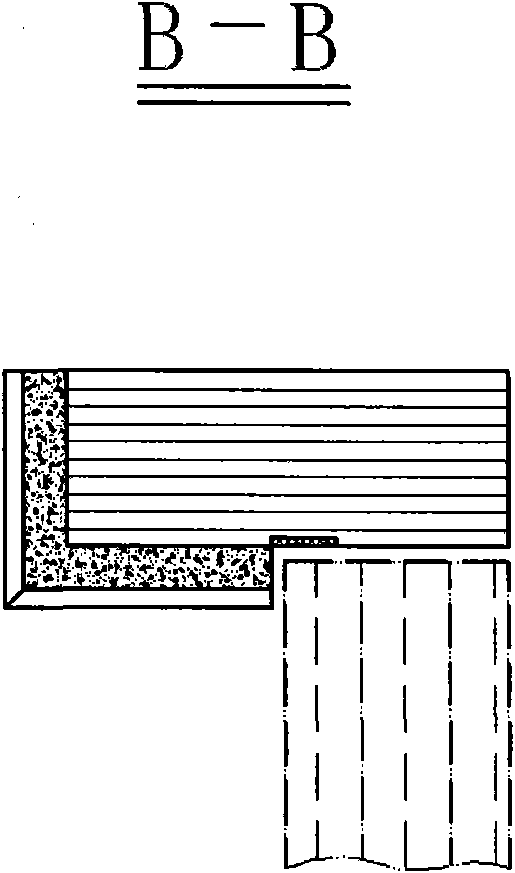

[0024] The specific implementation manner of the present invention will be described below in conjunction with the drawings. Such as figure 1 , figure 2 and image 3 As shown, the flame retardant laminated veneer lumber fire door frame provided by the present invention includes a frame 1, a fireproof expansion sealing strip 2, a fireproof board 3 and a decorative splint 4; the frame 1 is composed of vertical frames on the left and right sides and horizontal frames ; A fire-proof board 3 is pasted on the fire-receiving surface of the frame 1, and a decorative plywood 4 is pasted outside the fire-proof board 3; a groove is opened on the inner surface of the frame 1 in contact with the periphery of the door leaf 5, and a fireproof expansion board is pasted in the groove The sealing strip 2; the frame 1 is made of flame-retardant laminated veneer lumber, the longitudinal grain of the laminated veneer lumber is parallel to the vertical frame of the door frame or the length direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Border width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com