Method for manufacturing solid wood floorings by utilizing densified fast growing woods

A technology for solid wood flooring and fast-growing wood, applied in the direction of manufacturing tools, wood compression, wood processing appliances, etc., can solve the problems of high surface strength, low overall density, etc., to expand the scope of application, improve dimensional stability, and eliminate compressive residual stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] ①Preparation of poplar wood boards: saw the fast-growing poplar wood into boards, dry, plan, and process them into poplar wood boards with a moisture content of 19% and a thickness of 24.0mm according to the densification rate of 25%.

[0023] ② Densification treatment: Put the above-mentioned poplar board in a hot press at a temperature of 112°C and perform densification treatment according to the set thickness of 18mm, the pressure is 2.8MPa, and the time is 70min. After turning off the heat source of the hot press, The densified plate is kept in the hot press for 15 minutes and then taken out from the press;

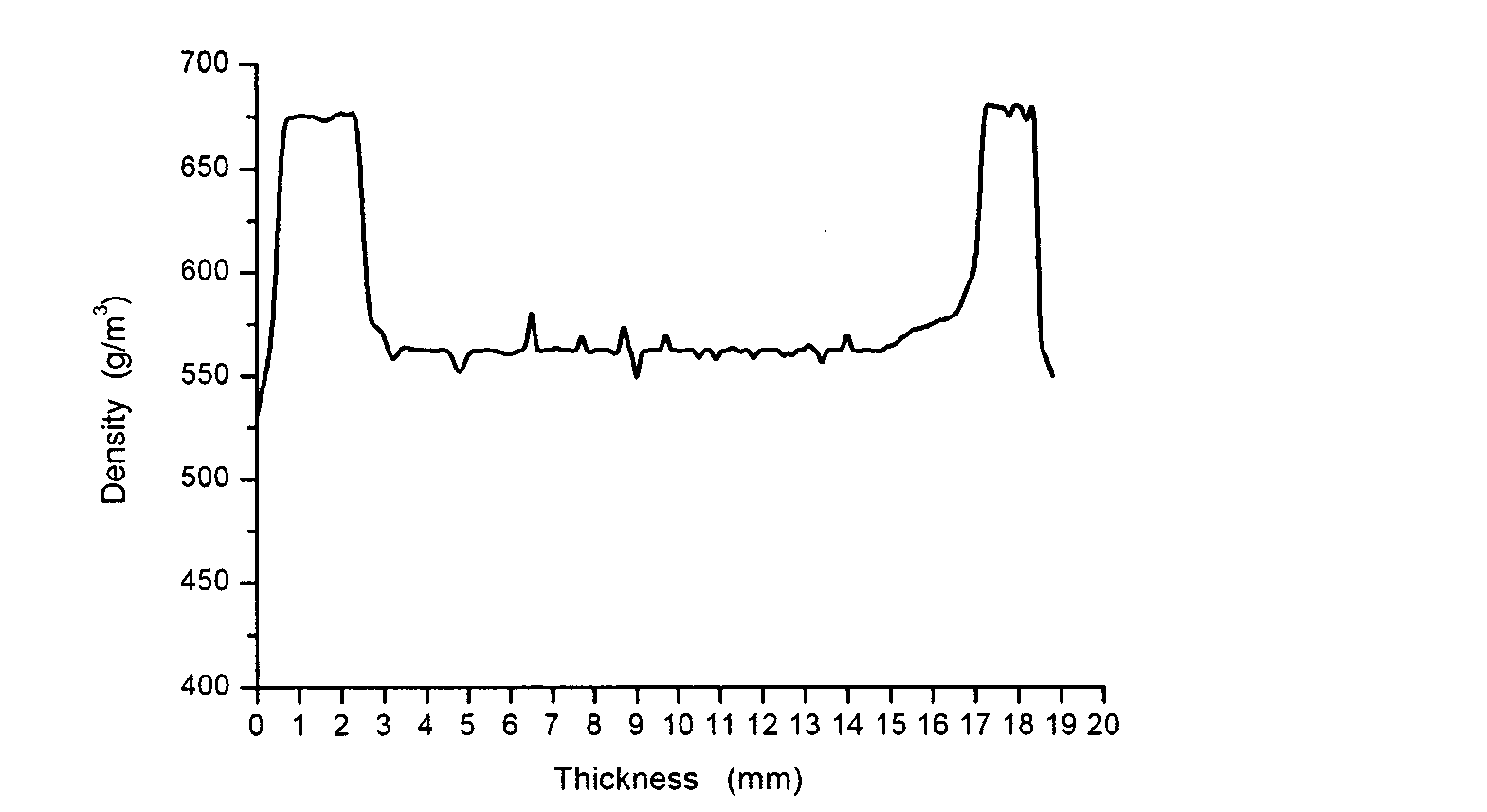

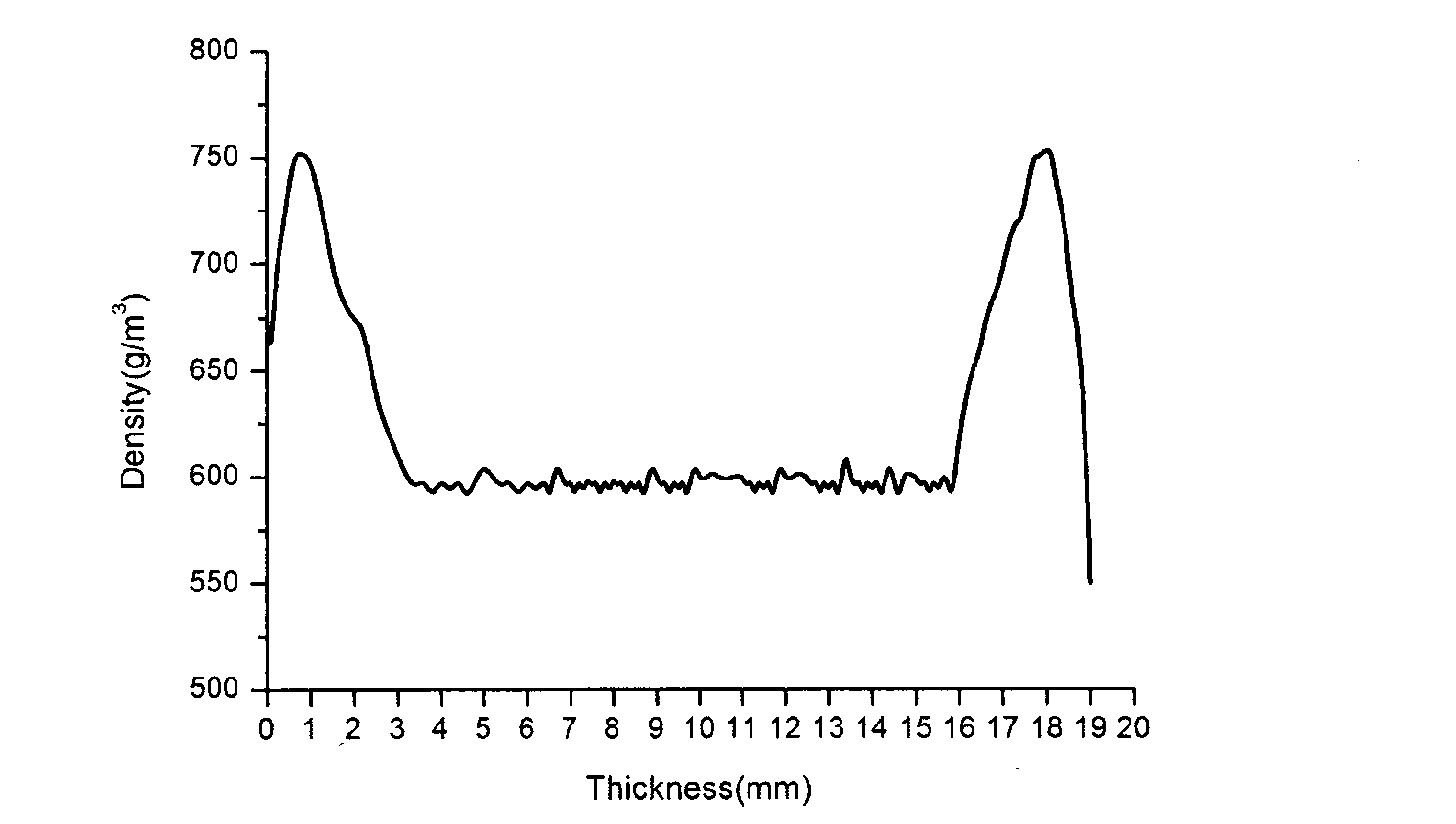

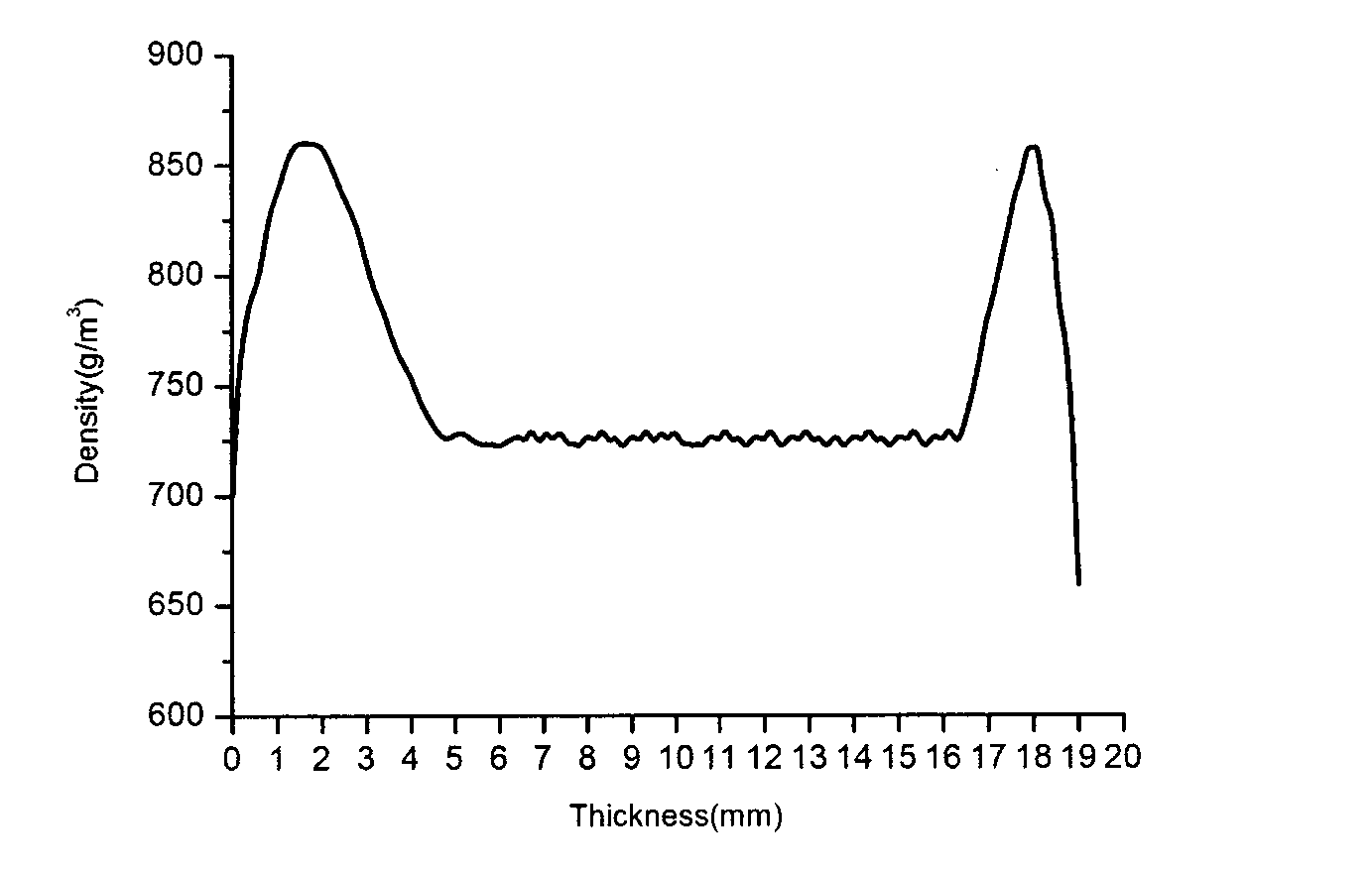

[0024] ③Health preservation: Place the densified poplar boards indoors for 24 hours to eliminate the residual stress formed during compression, and form a cross-sectional density gradient with low inside and high outside in the thickness direction of the board;

[0025] ④High-temperature heat treatment: place the cured poplar board in an oven at a temperature o...

Embodiment 2

[0030] ①Preparation of bamboo and willow boards: Saw the fast-growing bamboo willows into boards, dry, plan, and process them into bamboo and willow boards with a moisture content of 23% and a thickness of 27.1mm according to the densification rate of 30%;

[0031] ② Densification treatment: Put the above-mentioned bamboo and willow board in a hot press at a temperature of 115°C and perform densification treatment according to the set thickness of 19mm. The pressure is 2.5MPa and the time is 68min. After turning off the heat source of the hot press, The densified plate is kept in the hot press for 18 minutes and then taken out from the press;

[0032] ③Health preservation: Place the compacted bamboo and willow planks indoors for 24 hours to preserve the health, eliminate the residual stress formed during compression, and form a cross-sectional density gradient that is low inside and high outside in the thickness direction of the planks;

[0033] ④High-temperature heat treatment:...

Embodiment 3

[0038] ①Preparation of paulownia boards: sawing the fast-growing paulownia into boards, drying, planing, and processing into poplar boards with a moisture content of 28% and a thickness of 33.3mm according to a densification rate of 40%;

[0039] ② Surface densification treatment: Place the Paulownia board in a hot press at a temperature of 118°C and perform densification treatment according to the set thickness of 20mm. The pressure is 2MPa and the time is 66min. After turning off the heat source of the hot press, densification The plate is kept in the hot press for 22 minutes and then taken out from the press;

[0040] ③Preservation: Place the densified paulownia board indoors for 24 hours to cure the residual stress formed during compression, improve the dimensional stability of the densified wood, and form a cross-sectional density gradient that is low inside and high outside in the thickness direction of the board.

[0041] ④High-temperature heat treatment: place the cure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com