Retractor for safety belt and safety belt assembly

A retractor and seat belt technology, applied in the field of seat belts, achieves the effects of simple and controllable stress conditions, improved accuracy, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

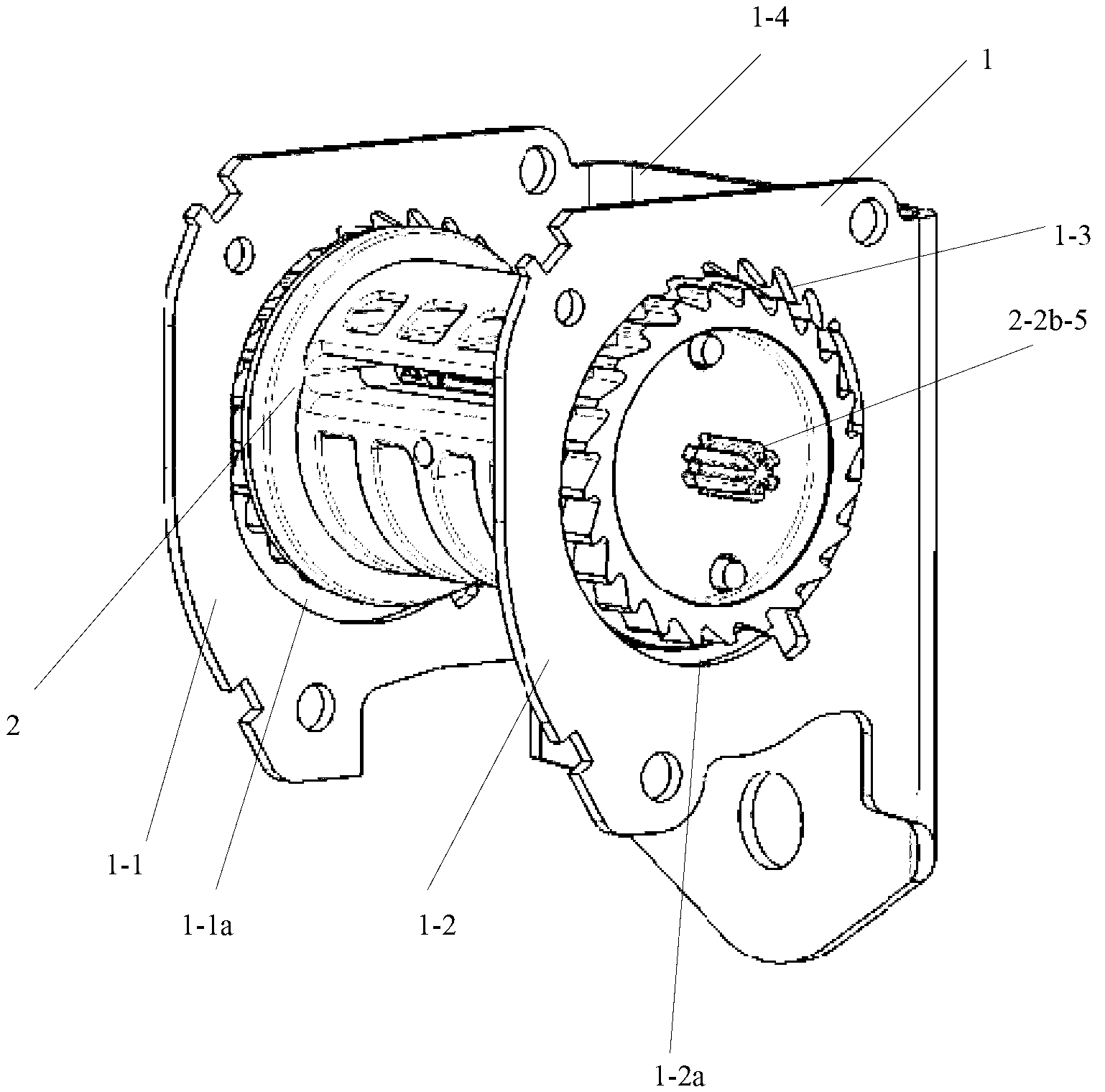

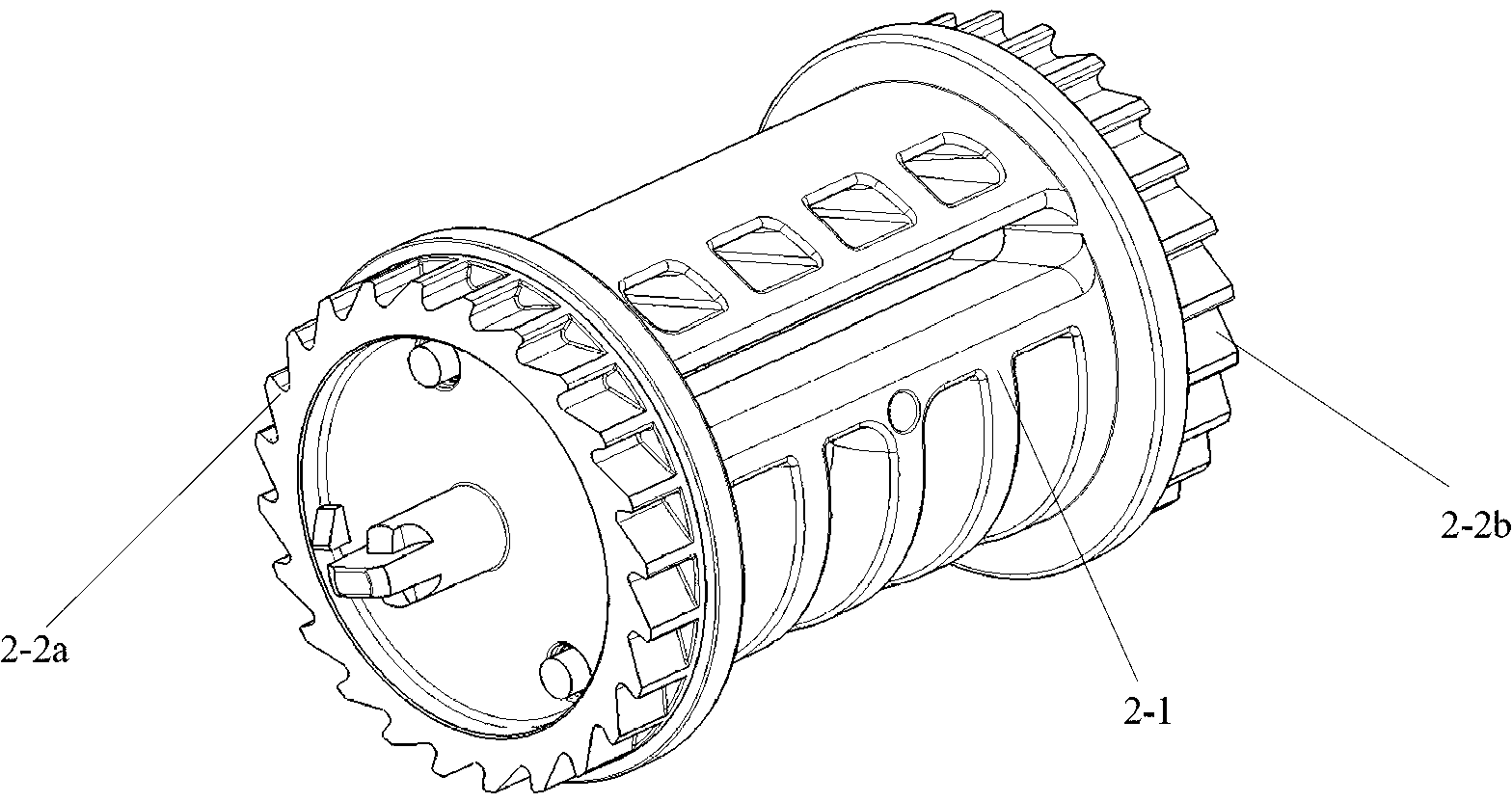

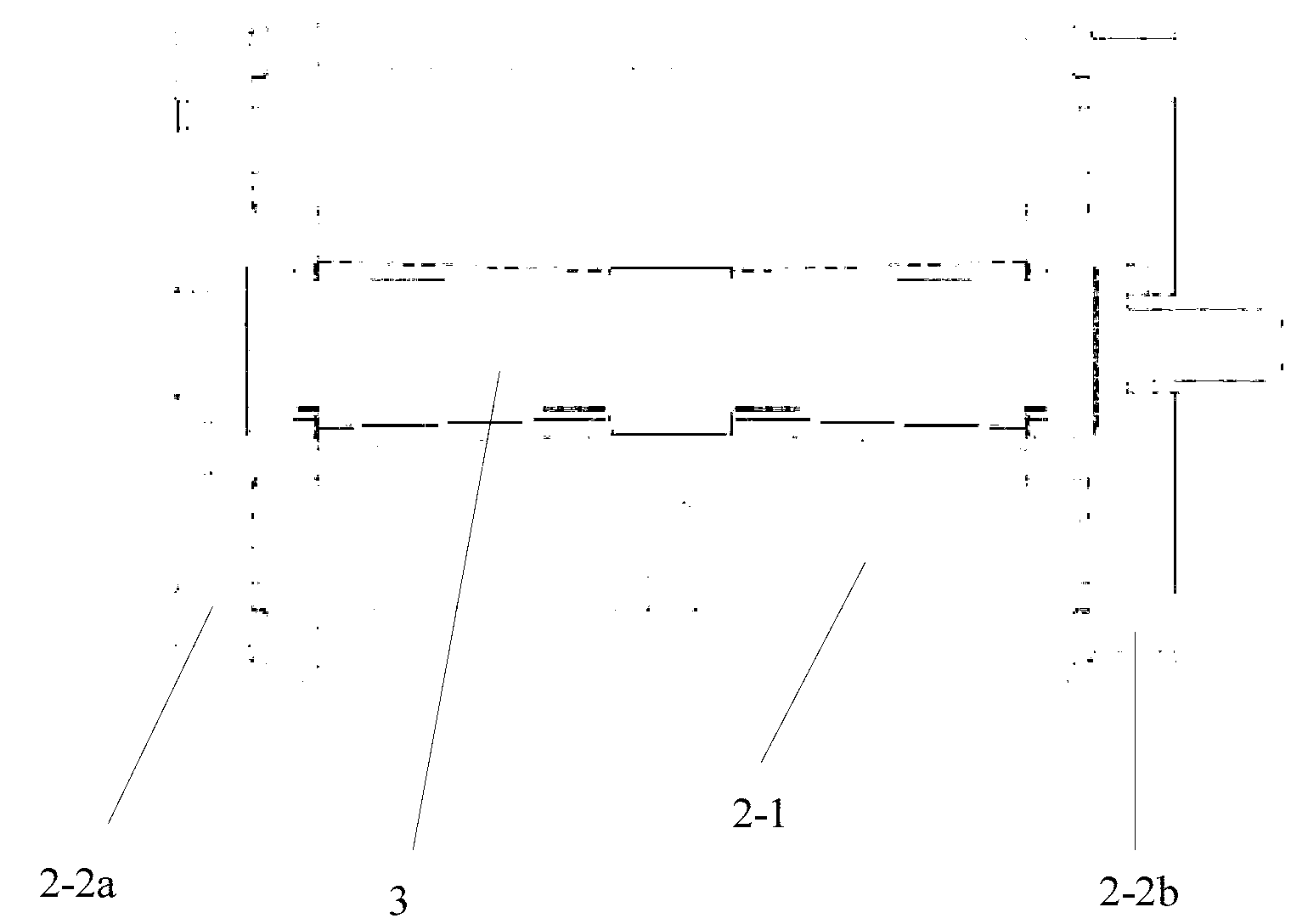

[0051] figure 1 It is a structural schematic diagram of the first embodiment of the retractor for safety belts of the present invention, figure 2 for figure 1 Schematic diagram of the scroll structure in ; image 3 for figure 2 A cross-sectional view along the axis of the reel; Figure 4 An exploded view of the assembly for the reel and torsion bar.

[0052] Please see figure 1 , in this embodiment, the retractor includes a retractor frame 1, a reel 2 and a torsion bar 3 ( Figure 4 shown in

[0053] Wherein, the retractor frame 1 is U-shaped, which includes two opposite side walls: a first side wall 1-1 and a second side wall 1-2. It also includes two third walls 1-4 connecting the first side wall 1-1 and the second side wall 1-2. Corresponding positions on the first side wall 1-1 and the second side wall 1-2 are respectively provided with a circular first through hole 1-1a and a second through hole 1-2a, on the two through holes The same position is provided with ...

no. 2 example

[0076] The difference between the retractor in this embodiment and the above-mentioned first embodiment is that the torsion bar is a separate two-stage structure, such as Figure 13 An exploded view of the reel assembly shown with the torsion bar assembly.

[0077] The torsion bar comprises two sections arranged coaxially: a first section 3a and a second section 3b. The two sections have the same axial length, and external teeth are arranged at the end of each section along the axial direction. When assembled as a whole, the two ends of the two torsion bars are butted together, the end faces are in contact with each other, and the outer teeth at the opposite ends are corresponding to each other. The external teeth at the opposite ends are generally equivalent to the peripheral external teeth in the middle of the torsion bar in the first embodiment. Its function and connection with the mandrel are the same as those of the above-mentioned first embodiment. The other two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com