Large-diameter and super-long reinforcement cage and construction method thereof

A technology of super-long steel cage and construction method, which is applied in the direction of foundation structure engineering, structural elements, sheet pile walls, etc., can solve the problems of welding quality inspection and technical intermittent time, and cannot meet the requirements of construction technology and construction period, and achieve promotion It has high application value, meets the construction period and quality requirements, and solves the effect of super-long reinforcement cage extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

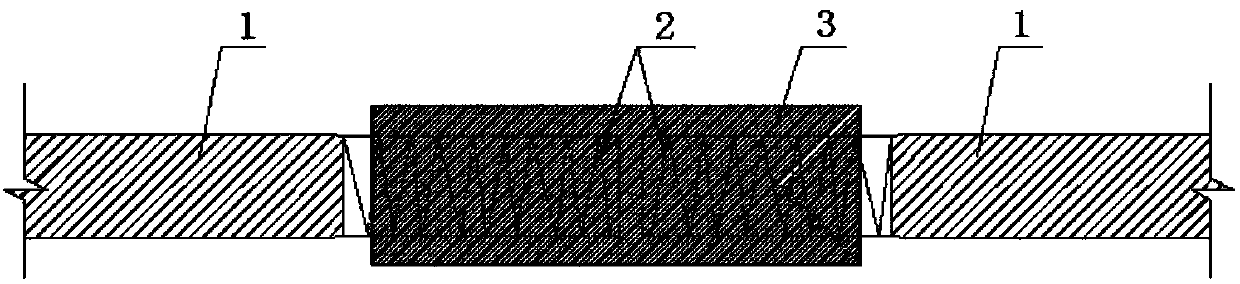

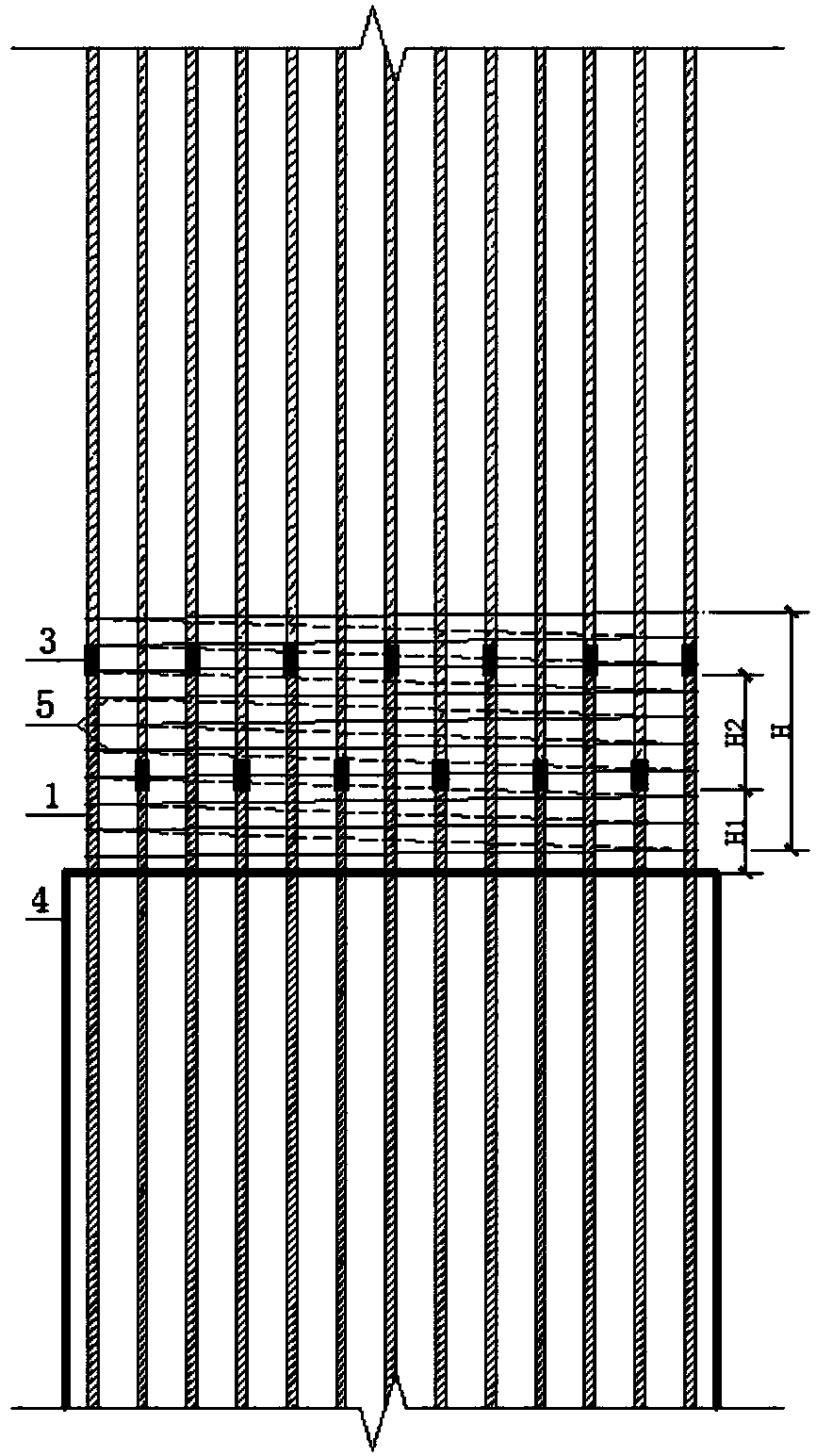

[0030] like figure 1 and figure 2 As shown, the present invention provides a large-diameter super-long reinforcement cage, which includes several sections of reinforcement cage units, each section of reinforcement cage unit includes several spaced and parallel arranged stiffeners, and the circumferential direction of several stiffeners Several main reinforcements 1 are arranged at equal intervals, and the main reinforcements 1 are welded together with the stiffeners. Both ends of each main reinforcement 1 are screw rods 2. The tubes 3 are connected as a whole, and stirrups 5 are also arranged in the circumferential direction of the joints of two adjacent steel cage units. Wherein, the length of the main reinforcement 1 is 12-15 meters, the diameter of each reinforcement cage unit is 800-2000 mm, and the distance between two adjacent stiffeners is 2 meters. In addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com