Automatic circulating feeding device for battens

A technology of automatic circulation and feeding device, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of insufficient chain gap, inability to achieve manipulator clamping action, low work efficiency, etc., to improve transfer efficiency, not easy The effect of bending deformation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

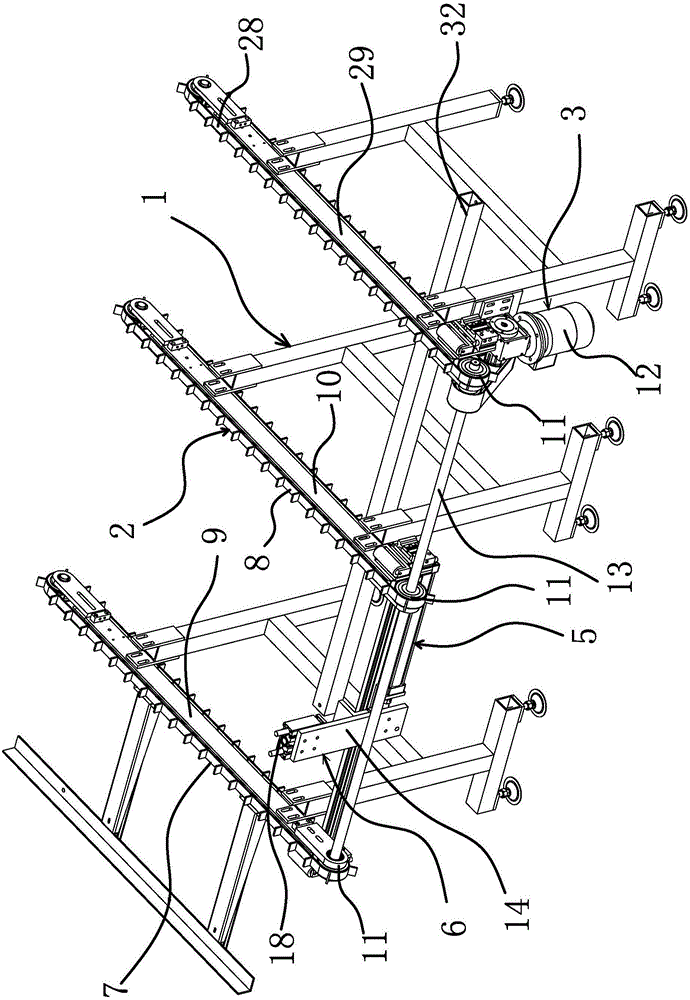

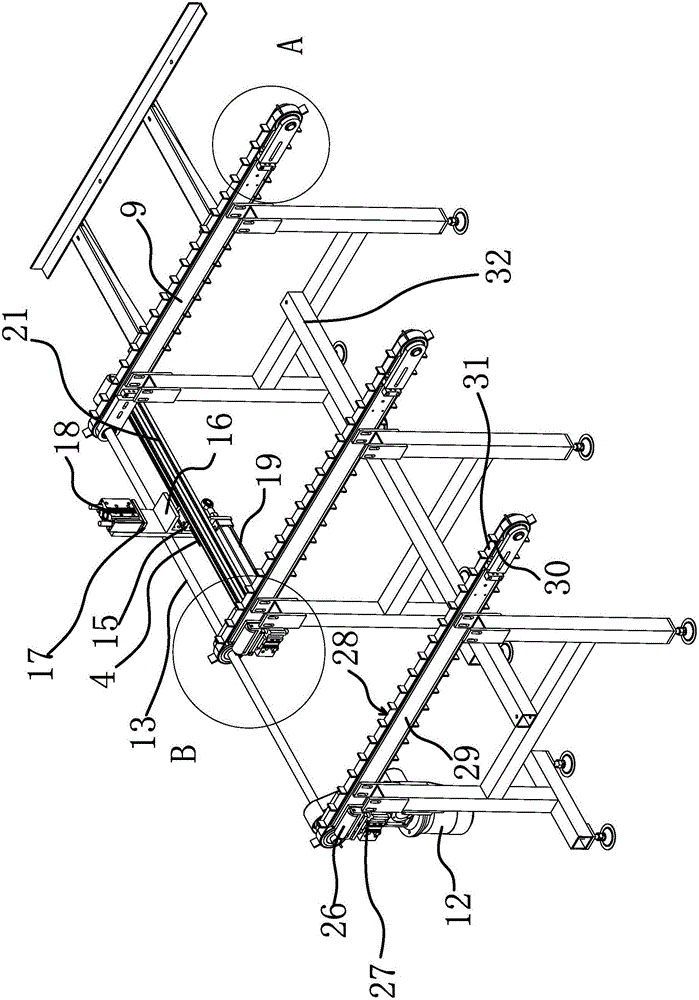

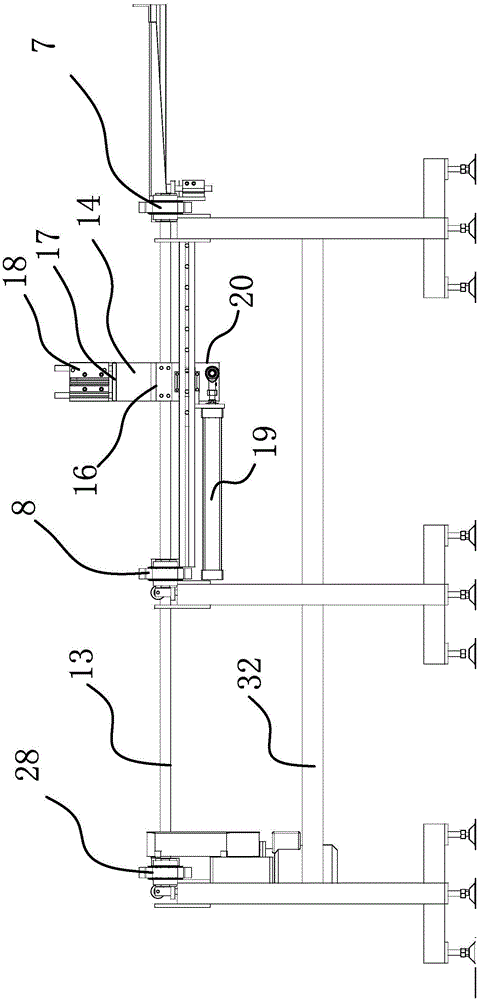

[0029] like figure 1and figure 2 Shown, this wooden bar automatic cycle feeding device comprises frame 1, and frame 1 comprises horizontal crossbeam one 9, horizontal crossbeam two 10 and the support 32 that is fixedly connected with the former two, the two of horizontal crossbeam one 9 and horizontal crossbeam two 10 The ends are connected with pulleys 11, and the frame 1 is also fixed with a horizontal guide rail 4, the sliding direction of the horizontal guide rail 4 is perpendicular to the transport direction of the conveyor belt assembly 2, and the horizontal guide rail 4 is slidably connected with a belt for clamping the conveyor belt assembly 2. The manipulator 6 for placing wooden strips, the frame 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com