Melamine decorative veneer hot-pressing concavo-convex forming process

A melamine, forming process technology, applied in the direction of manufacturing tools, wood processing appliances, wood veneer joints, etc., can solve the problems of cracking, easy bending and deformation of products, uneven thickness of products, etc., and achieve the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] As shown in the figure, a hot pressing concave-convex forming process for melamine decorative veneer includes the following steps:

[0019] A. Mix the softening agent and water to make a softening liquid, spray the softening liquid on both sides of the melamine veneer substrate until both sides are wetted, and fully soften the melamine veneer substrate, which is resistant to hard, brittle, curved, and easily broken The substrate is softened and modified, so that the fiber of the substrate wood has good flexibility and lubricating permeability;

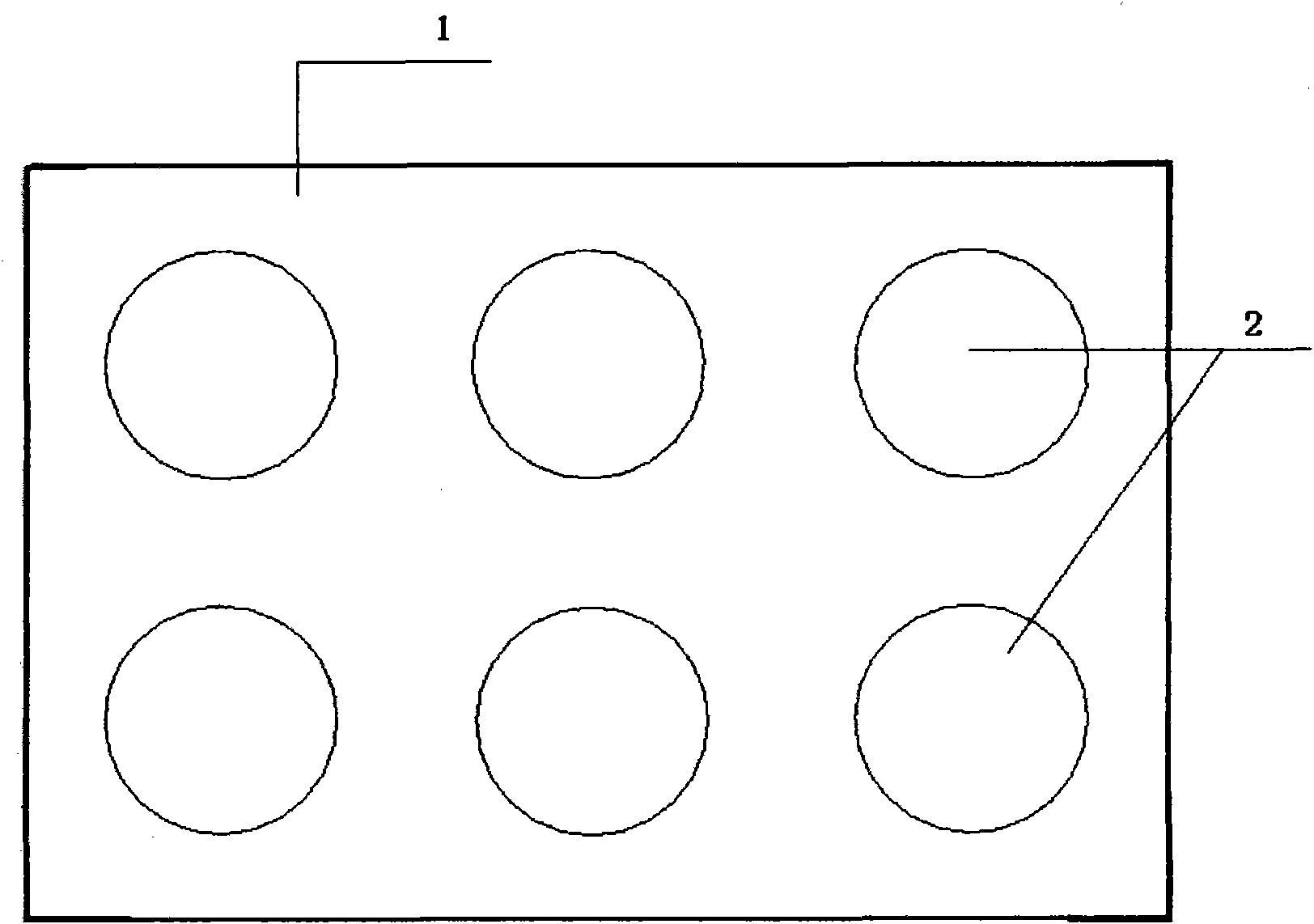

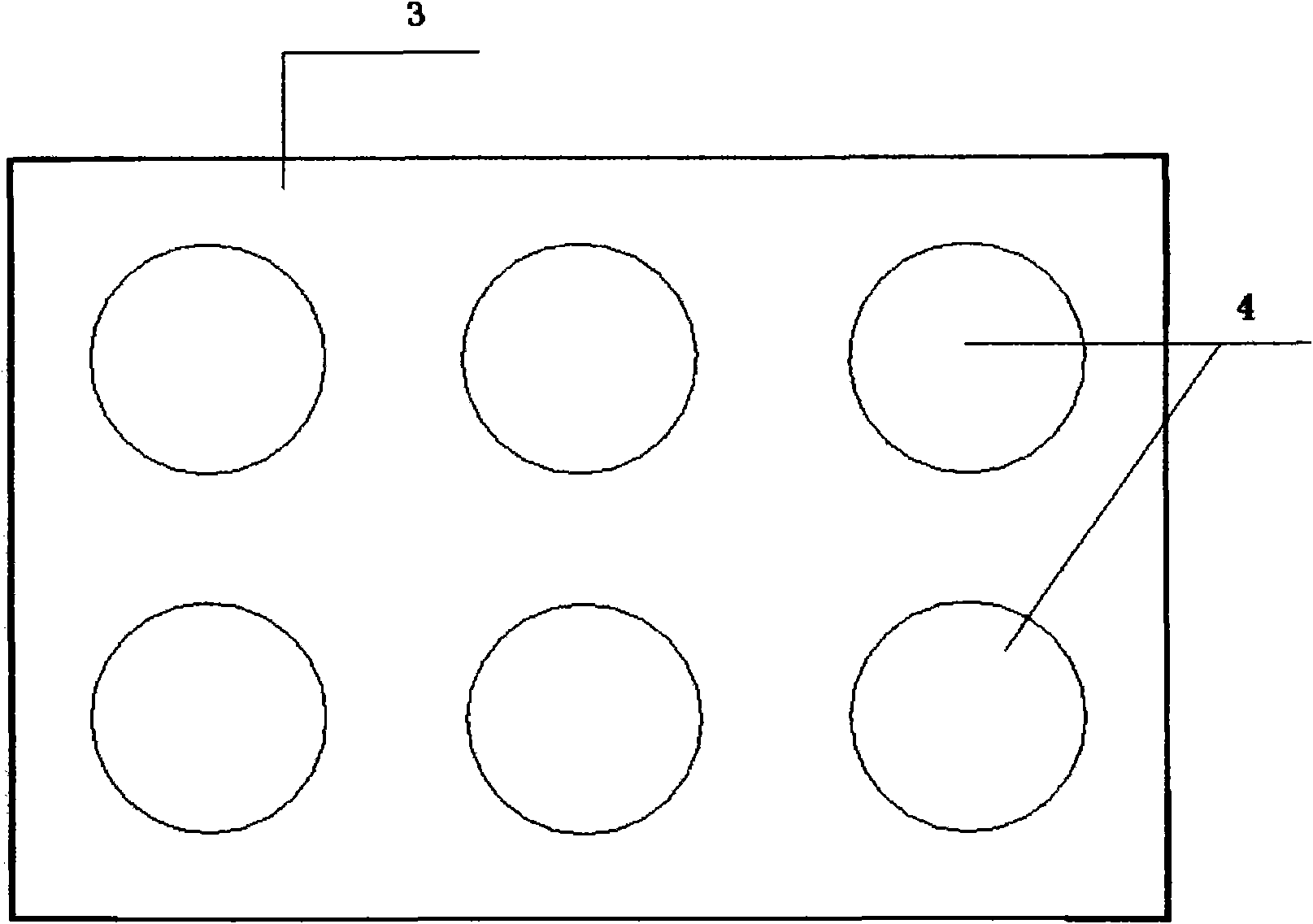

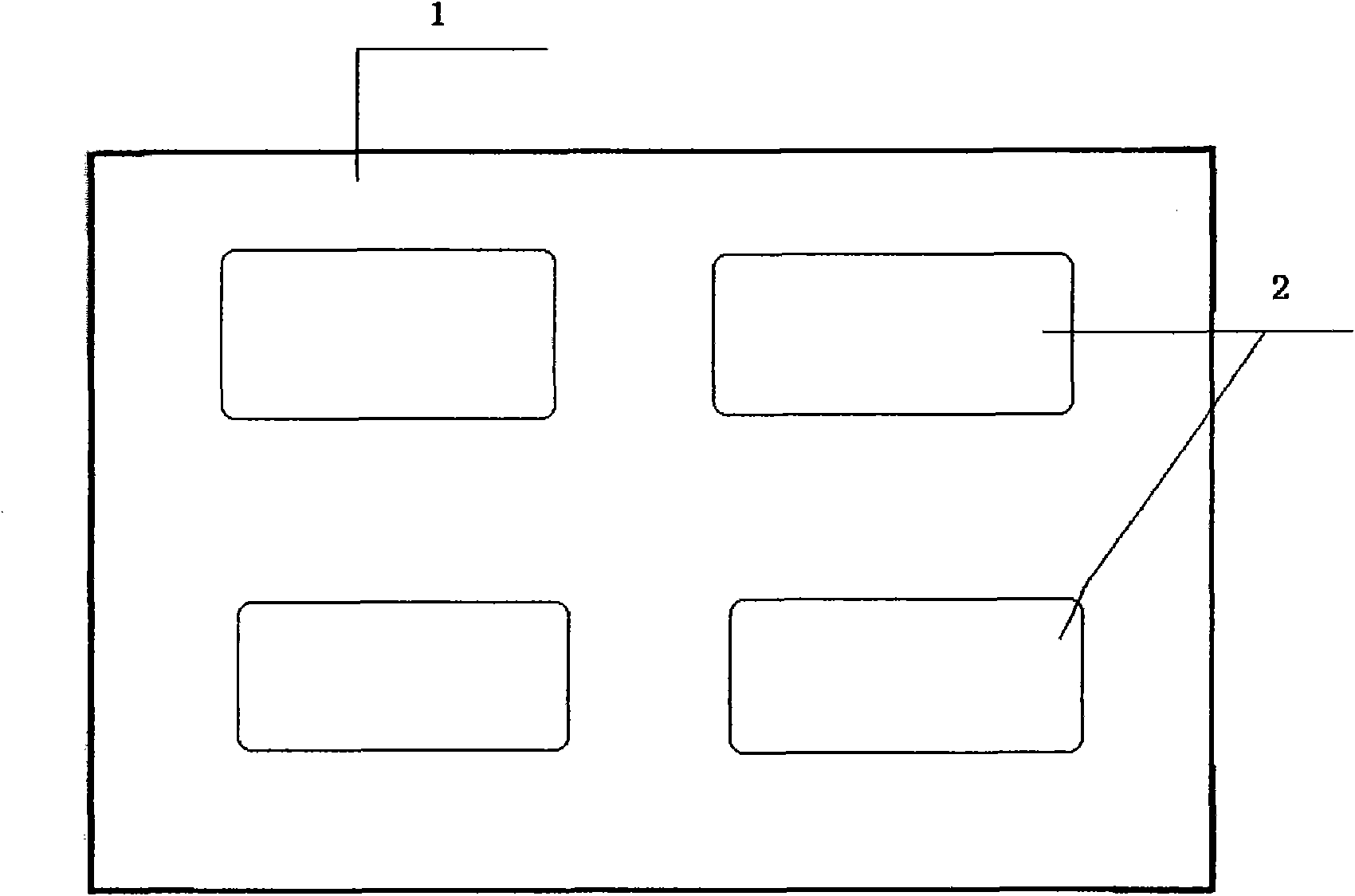

[0020] B. After the formed substrate is cooled, the veneer paper impregnated with melamine resin solution is laid on the substrate on the front of the substrate, and placed on the molding die for molding. The molding die includes an upper template 1 and a lower template 3, on the upper template There is a convex plate 2 and a groove 4 on the lower template 3. Place the substrate with the melamine veneer on the lower template 3 of the...

Embodiment 2

[0025] A hot pressing concave-convex forming process for melamine decorative veneer, which includes the following steps:

[0026] A. Mix the softener and water to make a softening liquid, spray the softening liquid on both sides of the melamine veneer substrate until both sides get wet to fully soften the melamine veneer substrate;

[0027] B. Lay the melamine veneer coated with melamine resin glue on both sides on the substrate, and place it on the molding die for molding. The molding die includes an upper template 1 and a lower template 3. The upper template 1 has a convex plate 2 and the lower template 3 There is a groove 4, the substrate with the melamine veneer is placed on the lower template 3 of the molding die, the upper template 1 is settled and pressed, the convex plate 2 on the upper template 1 and the groove 4 on the lower template 3 are closed and fully compressed. The substrate on which the melamine decorative veneer is pasted forms a concave-convex shape under the ac...

Embodiment 3

[0032] A hot pressing concave-convex forming process for melamine decorative veneer, which includes the following steps:

[0033] A. Mix the softener and water to make a softening liquid, spray the softening liquid on both sides of the melamine veneer substrate until both sides get wet to fully soften the melamine veneer substrate;

[0034] B. Lay the melamine veneer coated with melamine resin glue on both sides on the substrate, and place it on the molding die for molding. The molding die includes an upper template 1 and a lower template 3. The upper template 1 has a convex plate 2 and the lower template 3 There is a groove 4, the substrate with the melamine veneer is placed on the lower template 3 of the molding die, the upper template 1 is settled and pressed, the convex plate 2 on the upper template 1 and the groove 4 on the lower template 3 are closed and fully compressed. The substrate on which the melamine decorative veneer is pasted forms a concave-convex shape under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com