A kind of preparation method of lead storage battery positive plate

A lead-acid battery, positive plate technology, applied in lead-acid battery electrodes, positive electrodes, active material electrodes, etc., can solve problems affecting industrial application, low reliability of tab casting, poor tab strength, etc. high-rate and high-rate discharge performance, improved high-current charge-discharge capacity, and uniform plate current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

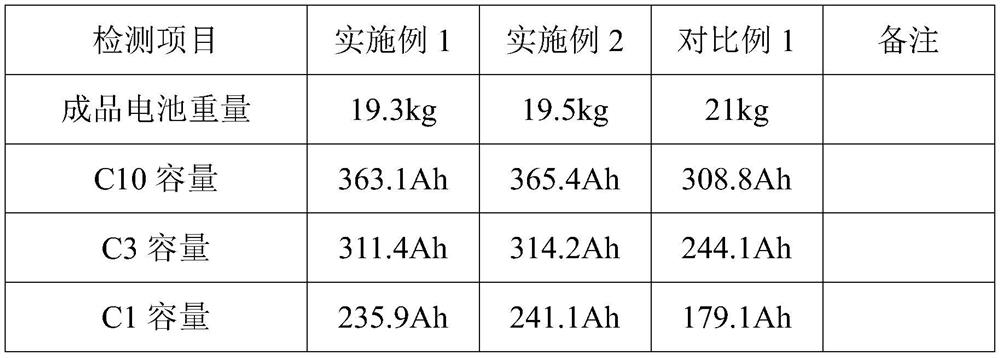

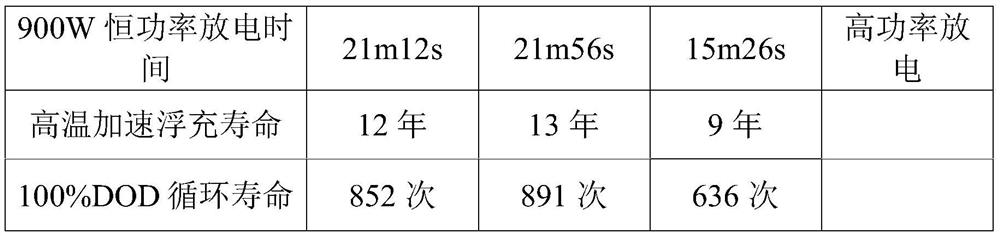

Examples

Embodiment 1

[0038] 1. Use lead foam material with a thickness of 5mm, a porosity of 95%, and a minimum pore diameter of 6mm. After 4 calendering, it is pressed to a thickness of 3.8mm, and punched into a grid lattice material with a length of 234mm and a width of 141mm.

[0039] Die-cast lead-tin alloy lugs and upper frames with a tin weight percentage of 1.8% in the width direction of the grid body. The thickness of the tabs is 4mm and the width is 18mm. The distance between the tabs and the edge of the grid body is 37.5mm. , equal to the length of the lattice body, 1mm higher than the lattice body in the width direction, and the size of the completed grid frame is 141mm wide, 235mm high, and 4mm thick.

[0040] 2. Lead paste components: lead powder 100kg, 1.4g / cm 3 4.13kg of dilute sulfuric acid, 19.3kg of deionized water, and 0.05kg of Teflon solution with a mass concentration of 30%.

[0041] Plate spraying, spray gun pressure 0.08MPa, finished plate size is 141mm wide, 235mm high, 4...

Embodiment 2

[0044] 1. Use lead foam material with a thickness of 8.5mm, a porosity of 90%, and a minimum pore diameter of 10mm. After 9 calendering, it is pressed to a thickness of 3.8mm, and punched into a grid lattice material with a length of 234mm and a width of 141mm.

[0045] Die-cast lead-tin alloy tabs and upper frames with a tin weight percentage of 30% in the width direction of the grid body. The tabs are 4mm thick and 18mm wide. The distance between the tabs and the edge of the grid body is 37.5mm, and the upper frame is 4mm thick and 4mm wide. , equal to the length of the lattice body, 1mm higher than the lattice body in the width direction, and the size of the completed grid frame is 141mm wide, 235mm high, and 4mm thick.

[0046] 2. Lead paste components: lead powder 100kg, 1.4g / cm 3 2.56kg of dilute sulfuric acid, 20.5kg of deionized water, and 0.1kg of Teflon solution with a mass concentration of 15%.

[0047] Plate spraying, spray gun pressure 0.04MPa, finished plate siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com