Indium tin oxide (ITO) stereo electrode, preparation method and preparation device thereof as well as preparation method of solar battery

A solar cell, indium tin oxide technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of large sheet resistance, damage, and high equipment cost, reduce the probability of damage, increase the contact area, The effect of uniform current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

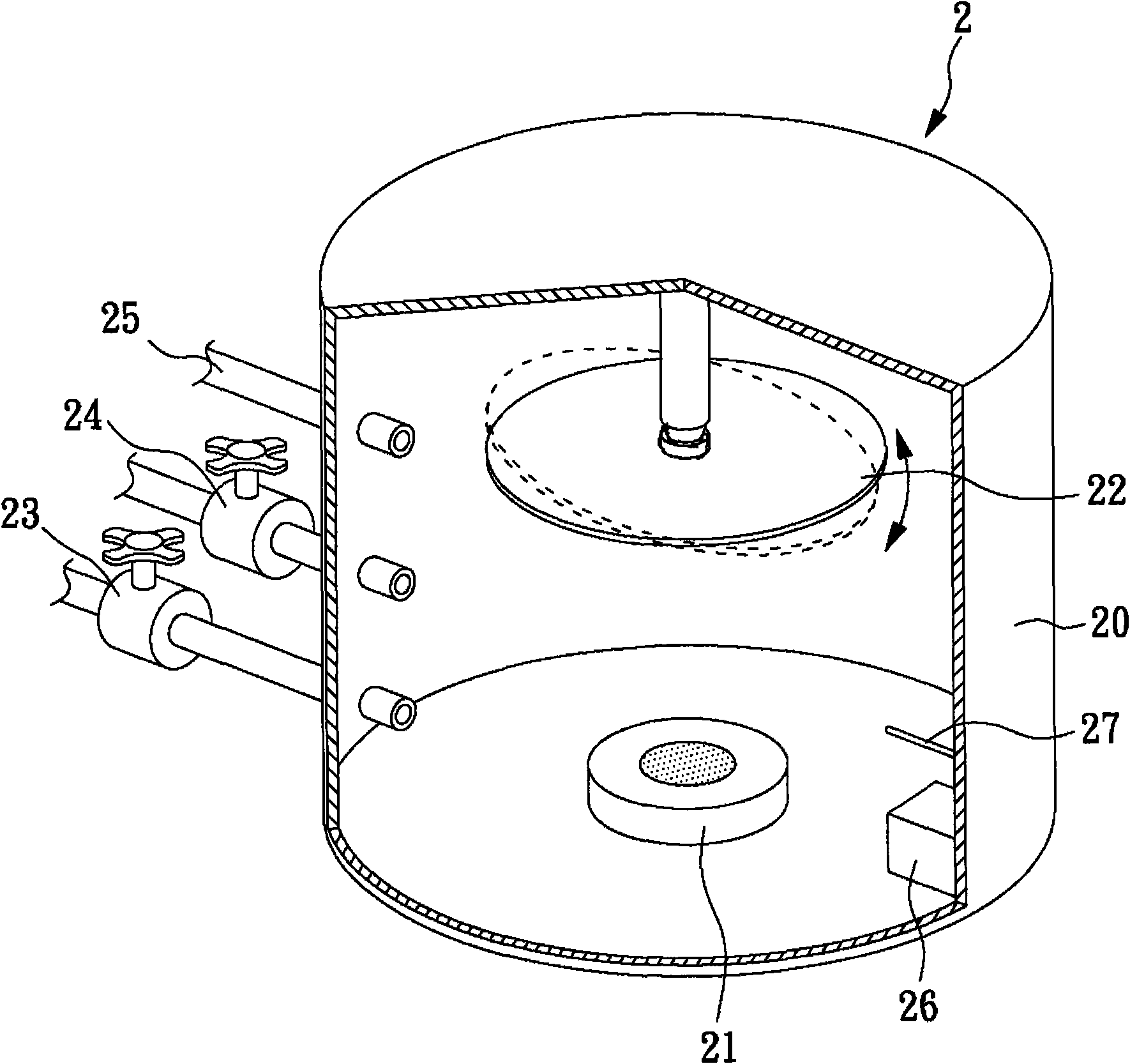

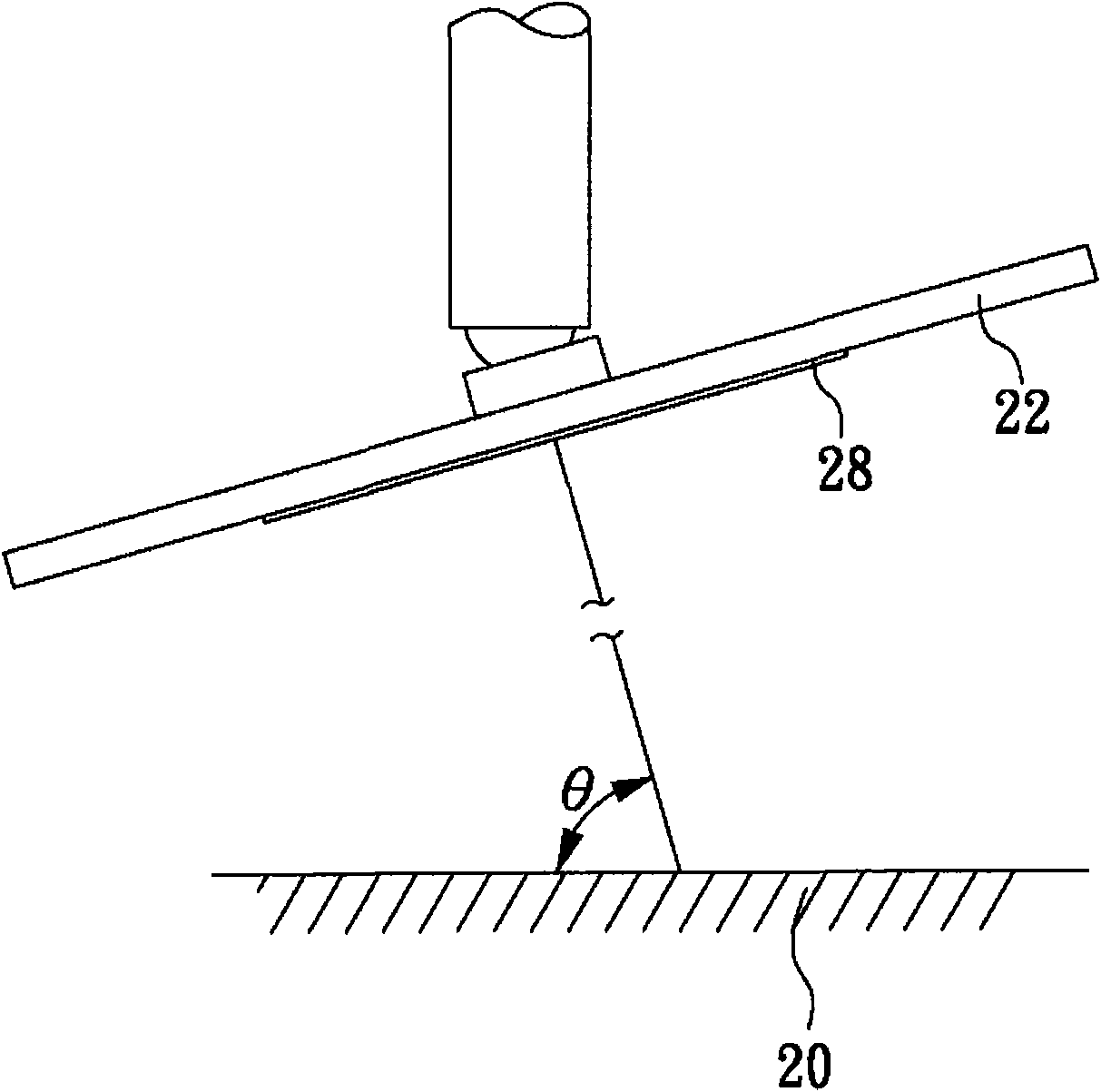

[0052] Such as figure 2 Shown is the vapor deposition machine 2 of this embodiment for vapor deposition of a substrate with conductive material attached to the surface, which includes: a reaction chamber 20, an vapor deposition unit 21, a substrate support base 22, and a nitrogen supply valve 23 , An oxygen supply valve 24, an exhaust pipe 25, a heater 26, and a thermometer 27. Wherein, the evaporation unit 21 is disposed at the bottom of the reaction chamber 20, and the substrate support base 22 is disposed at the top of the reaction chamber 20. When the substrate support 22 is equipped with a substrate 28 (such as image 3 When shown), the normal direction of the substrate 28 and the bottom of the reaction chamber 20 can be adjusted to form an included angle θ of 0 to 90 degrees.

Embodiment 2

[0054] Such as Figure 4 Shown is the vapor deposition machine 2 of this embodiment for vapor deposition of a substrate with a conductive material on its surface. In addition to having the same features as the vapor deposition machine 2 of Embodiment 1, the vapor deposition machine 2 of this embodiment also It includes a rotating table 29, which is arranged between the substrate support base 22 and the top of the reaction chamber 20. The rotation of the rotating table 29 allows the substrate support base 22 to revolve relative to the position of the evaporation unit 21 in the reaction chamber 20. Transform.

Embodiment 3

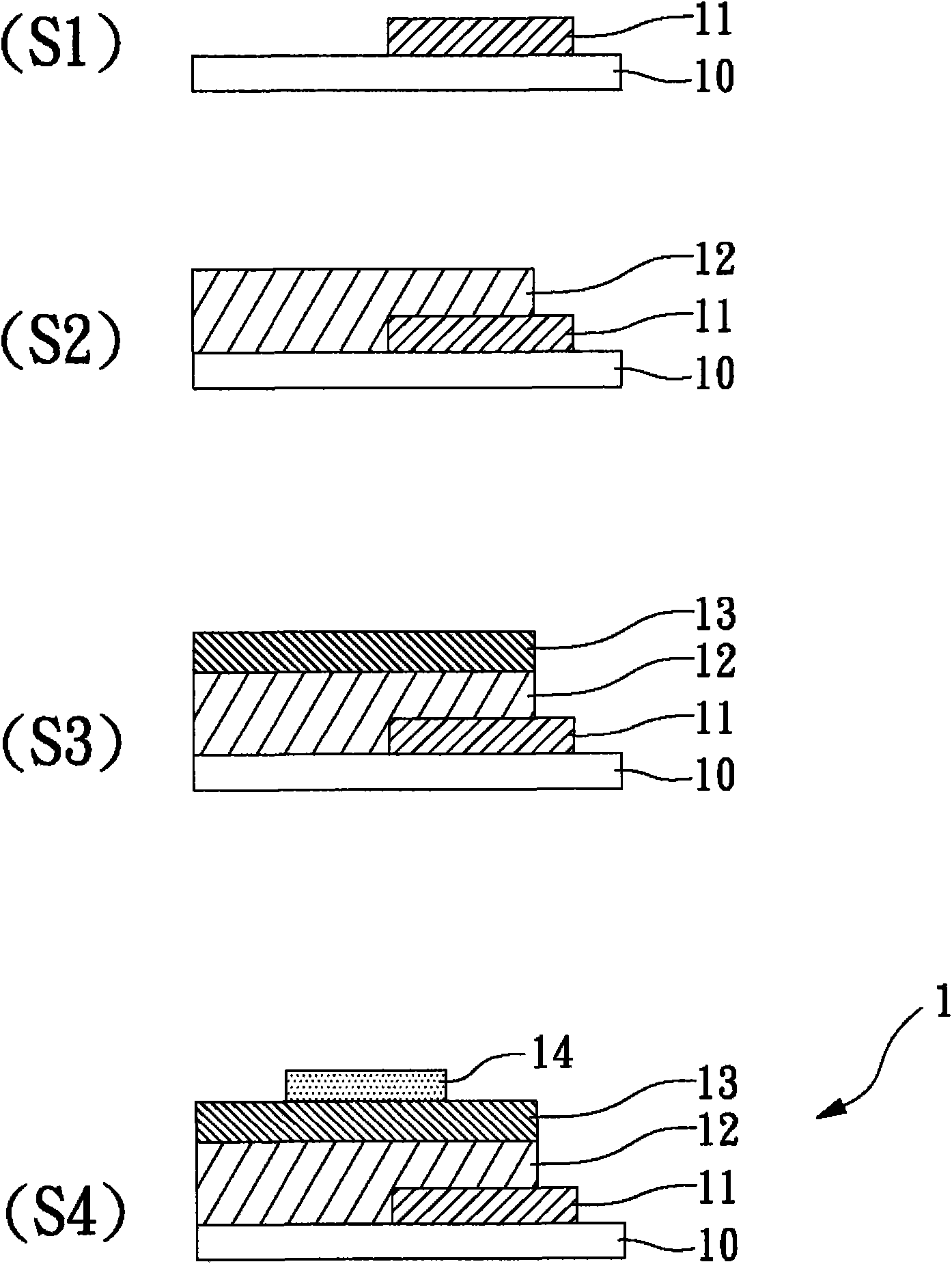

[0055] Example 3: Preparation of indium tin oxide three-dimensional electrode

[0056] Use as figure 2 The vapor deposition machine 2 of Embodiment 1 is shown to prepare the indium tin oxide three-dimensional electrode of this embodiment. Please also refer to figure 2 and image 3 , First, (A) mount the substrate 28 with a conductive layer on the surface on the substrate support 22 in the reaction chamber 20, and make the normal direction of the substrate 28 and the bottom of the reaction chamber form 0 to 90 degrees (preferably The included angle θ is about 5 to 85 degrees, and more preferably about 60 to 75 degrees), the included angle θ in this embodiment is 67 degrees. Next, (B) Nitrogen and oxygen are supplied from the nitrogen supply valve 23 and the oxygen supply valve 24, respectively, and the flow ratio of the supplied oxygen to the nitrogen is controlled to 0.5 or less, and the pressure in the reaction chamber 20 is maintained at 10 -6 To 10 -3 Within the pressure ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com