Fuel cell stack bandage type pressing assembly structure and design method thereof

A fuel cell stack and assembly structure technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of unstable expansion and contraction rate, uneven current distribution, inconvenient maintenance and maintenance, and achieves compact structure and current distribution. The effect of uniformity and thickness variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

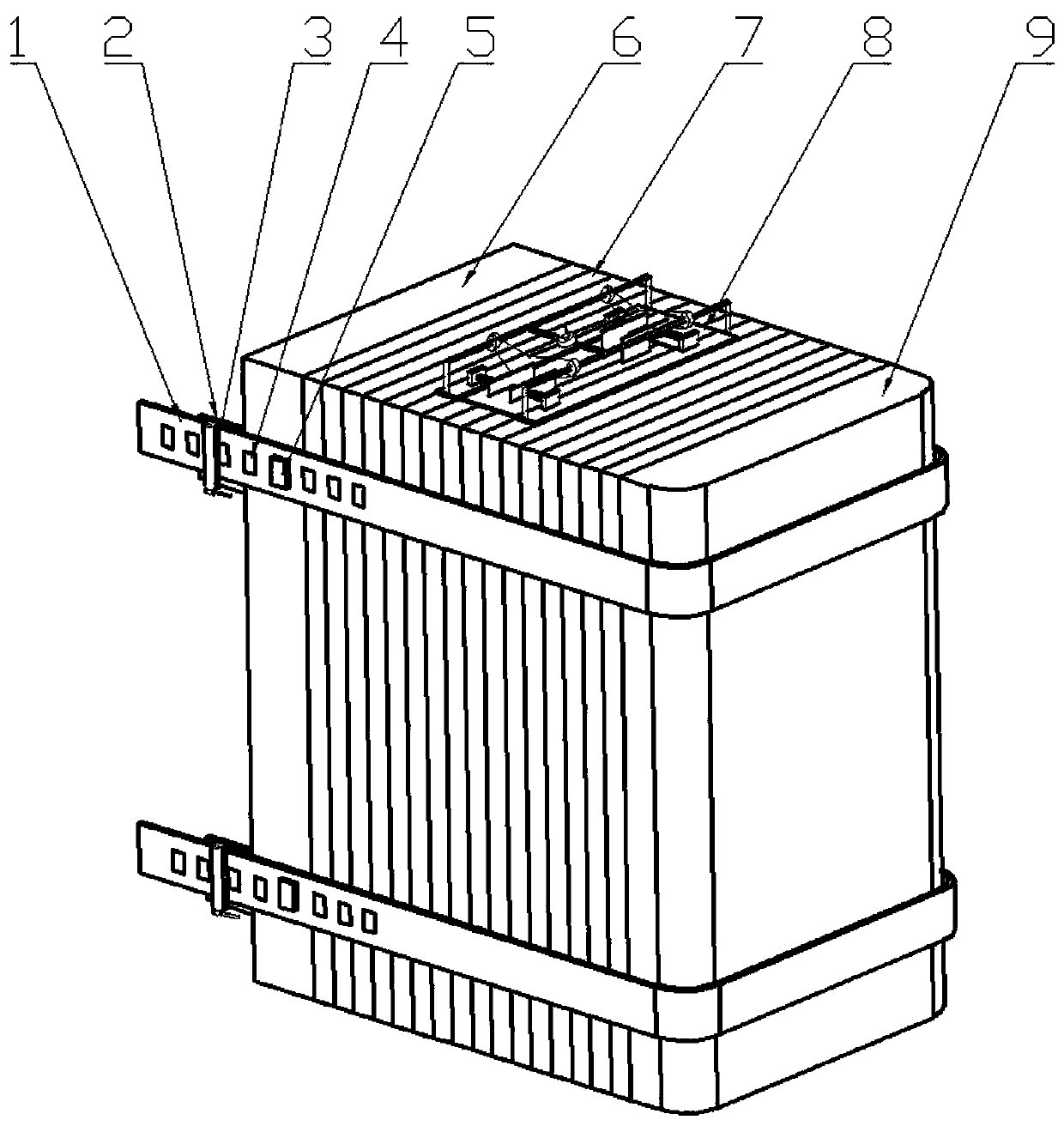

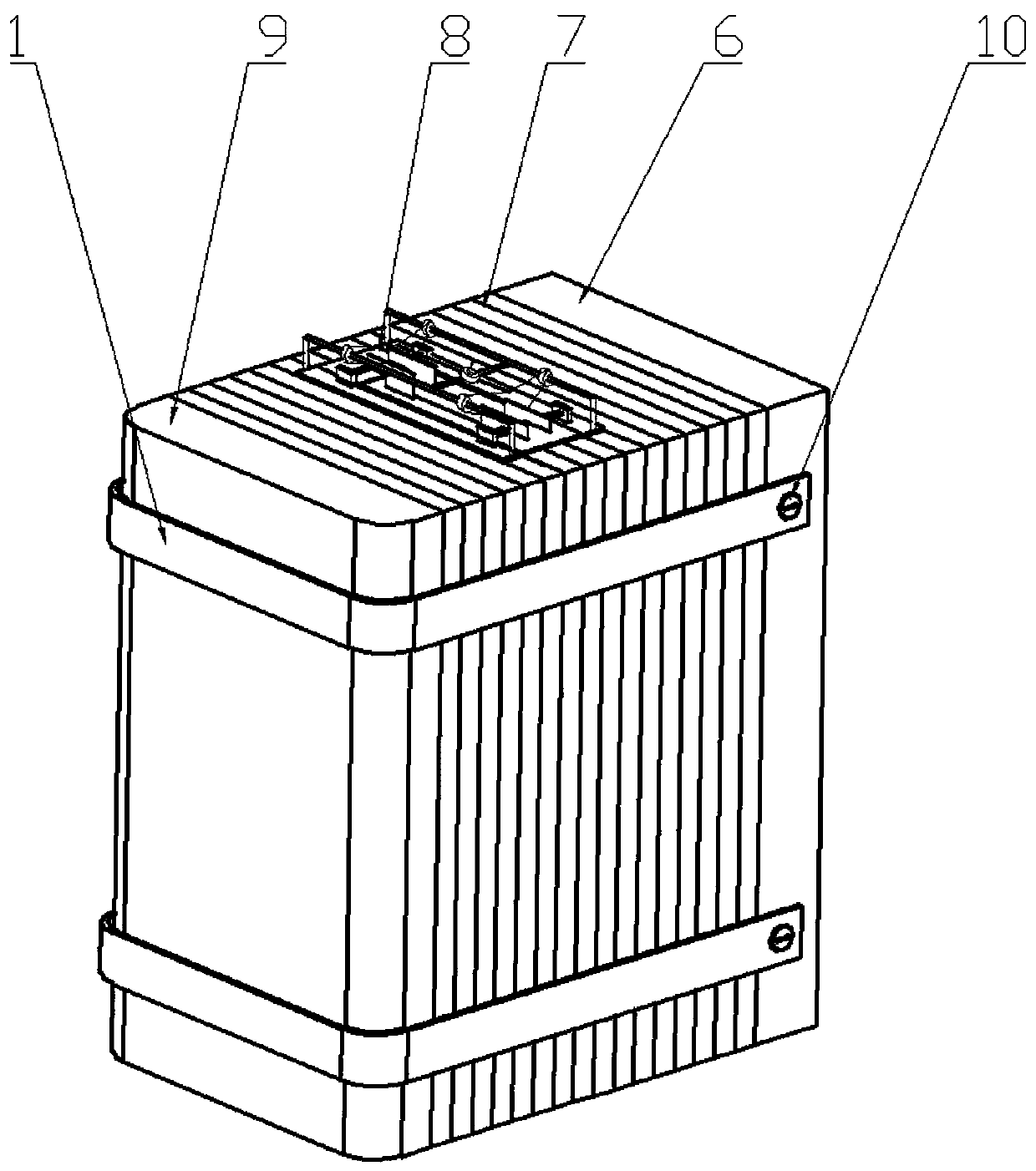

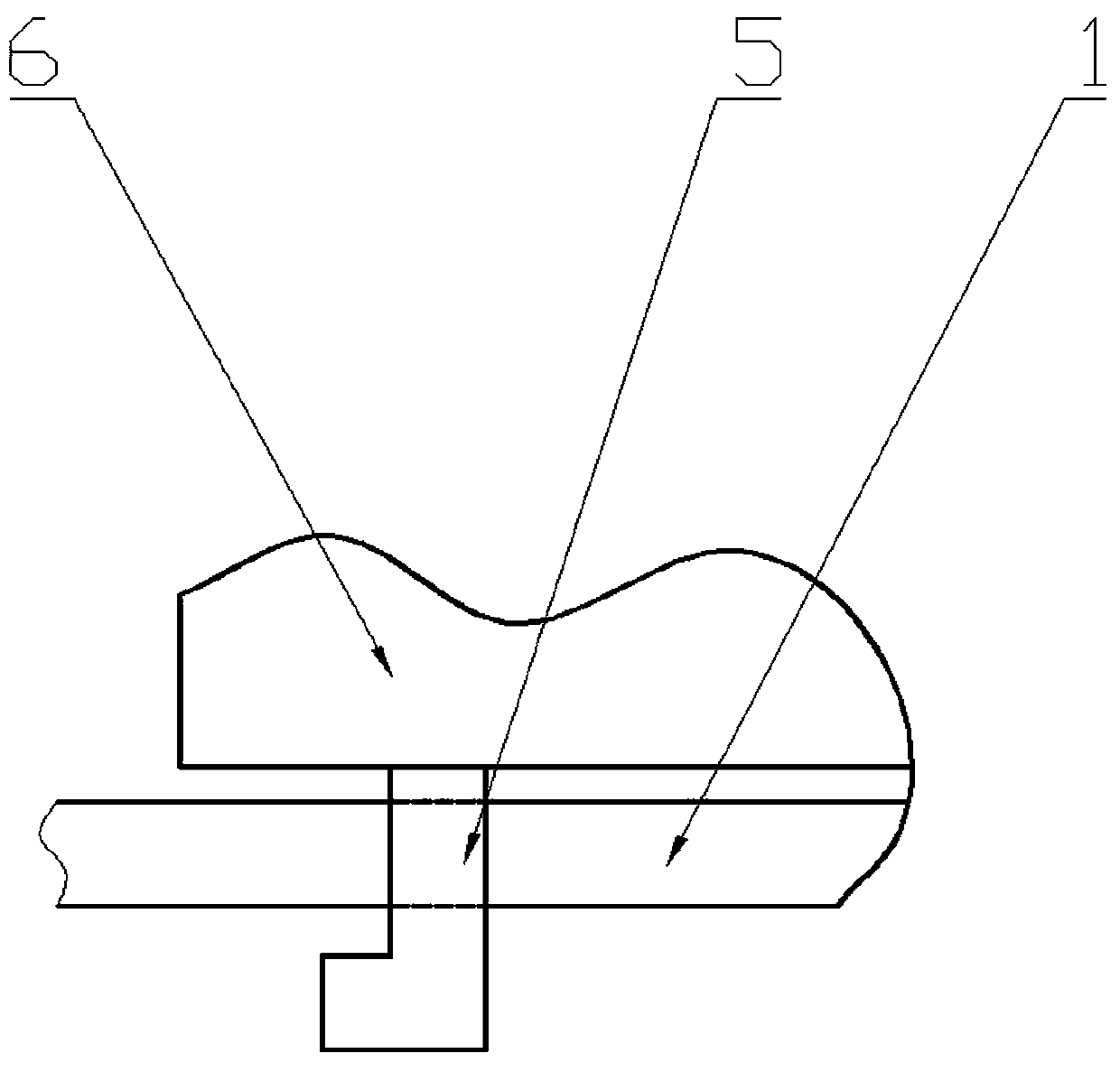

[0031] Example: such as Figure 1-6 As shown, a fuel cell stack strap-type compression assembly structure includes 16 fuel cells 7, one end of the fuel cell 7 is provided with a main end plate 6, the other end of the fuel cell is provided with an auxiliary end plate 9, and the main end plate 6 Two compression bands 1 are arranged between the outer wall and the outer wall of the auxiliary end plate 9, and a fixing screw 10 is threadedly connected and fixed to the main end plate 6 between one end of the compression band 1 and the outer wall of the main end plate 6, and the other end of the compression band 1 is connected to the outer wall of the main end plate 6. The outer wall of the main end plate 6 is provided with a hook pin 5 that is engaged and fixed with the main end plate 6 , and the compression belt 1 is provided with 8 belt holes 4 that are movable and limit nested with the hook pin 5 . The rear end of the hook pin 5 is provided with a clamping frame 2 integrated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com