A kind of sheet and its manufacturing method

A manufacturing method, sheet technology, applied in chemical instruments and methods, textiles and papermaking, nanotechnology for materials and surface science, etc., which can solve problems such as handling and processability are not necessarily good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091]

[0092] Sodium dodecylbenzenesulfonate (SDBS) was used as a dispersant, water was used as a dispersion medium, and 500 mL of SDBS 1 mass % aqueous solution was prepared. 1.0 g of SGCNT (manufactured by Zeon Nano Technology Co., Ltd., "ZEONANO (registered trademark) SG101" as a single-layer CNT) was added thereto, BET specific surface area: 1050 m 2 / g, average diameter: 3.3nm, average length: 400μm, t-curve convex upward (inflection point position: 0.6nm), internal specific surface area S2 / total specific surface area S1: 0.24), to obtain a coarse dispersion containing SDBS as a dispersant liquid. This crude dispersion containing monolayer CNT was filled into a high-pressure homogenizer (manufactured by Beryu corp., product name "BERYUSYSTEM PRO") having a multi-stage pressure control device (multi-stage pressure reducer) that loads back pressure at the time of dispersion , the dispersion treatment of the coarse dispersion was carried out at a pressure of 100 MPa. S...

Embodiment 2

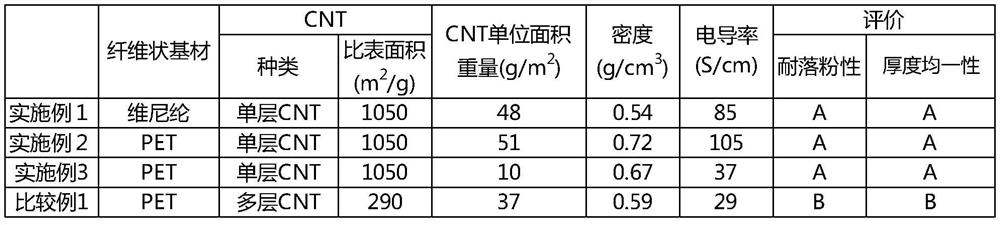

[0098] Instead of vinylon nonwoven fabric, PET nonwoven fabric (manufactured by Hirose seikou co., ltd., product number: 05TH-36, air permeability: 20cc / cm 2 / s) except having used it as a fibrous base material, it carried out similarly to Example 1, and obtained the sheet|seat. Various measurements and evaluations were performed on the obtained sheet according to the above-mentioned methods. The results are shown in Table 1.

Embodiment 3

[0100] A sheet was obtained in the same manner as in Example 2, except that the conditions of the contact step and the cleaning step were changed during production of the sheet. Various measurements and evaluations were performed on the obtained sheet according to the above-mentioned methods. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com