Engage the shift fork of the shifting mechanism

A switching mechanism and shift fork technology, which is applied to clutches, mechanical equipment, mechanical drive clutches, etc., can solve the problems of sheet shedding, prevent peeling or cracks, reduce processing hours, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

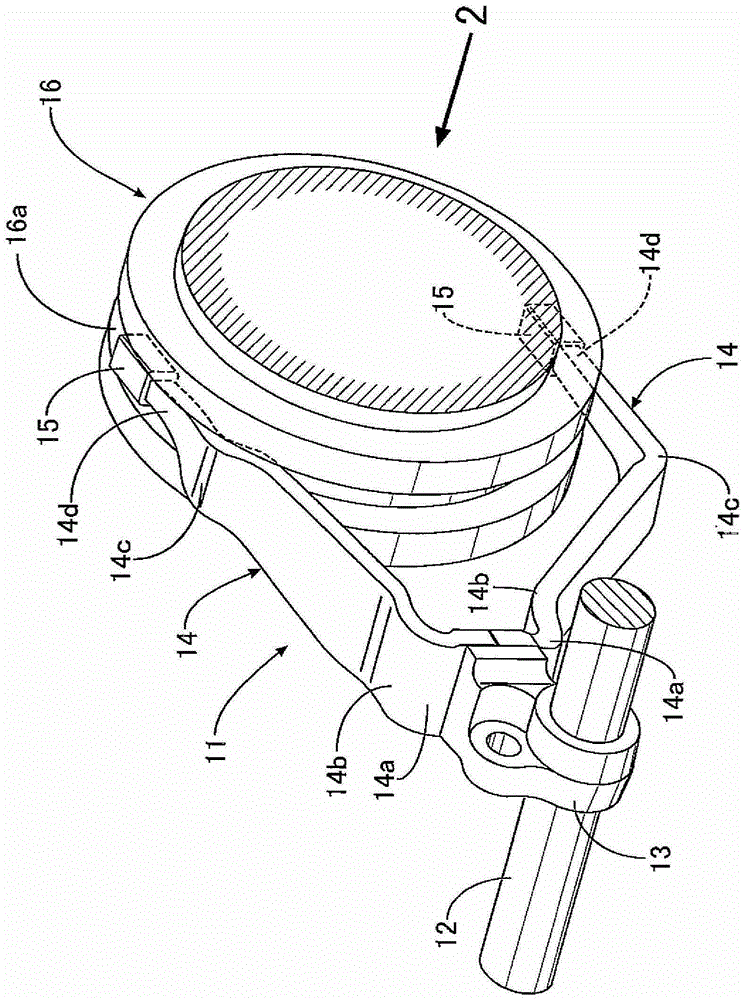

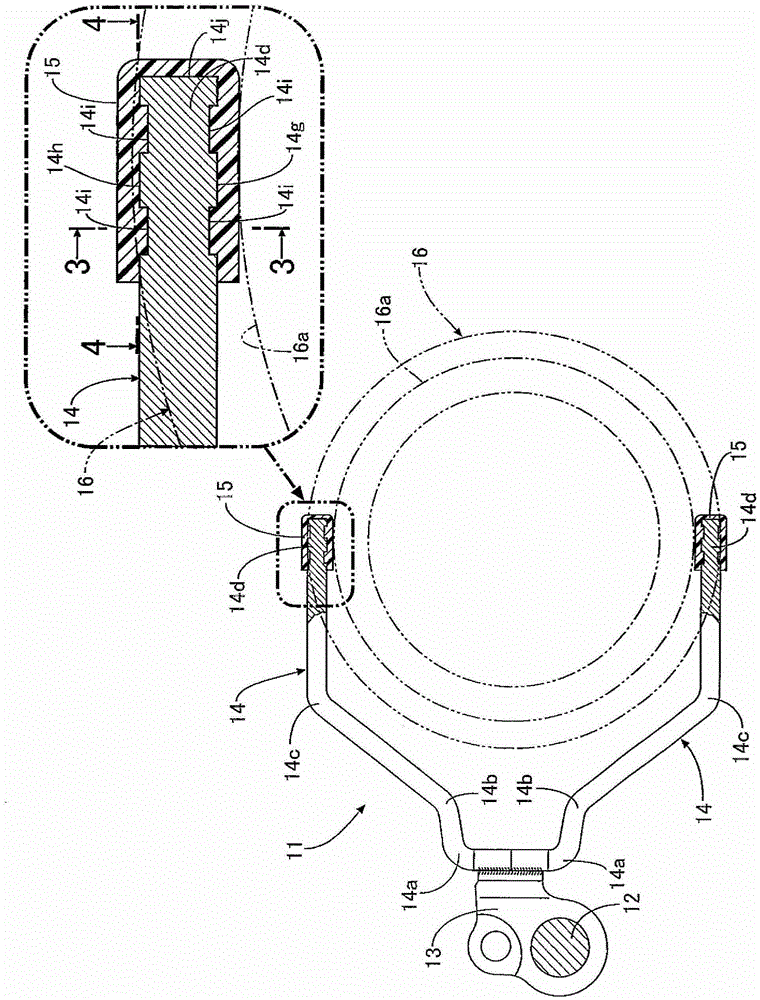

[0038] Below, based on Figure 1 ~ Figure 4 A first embodiment of the present invention will be described.

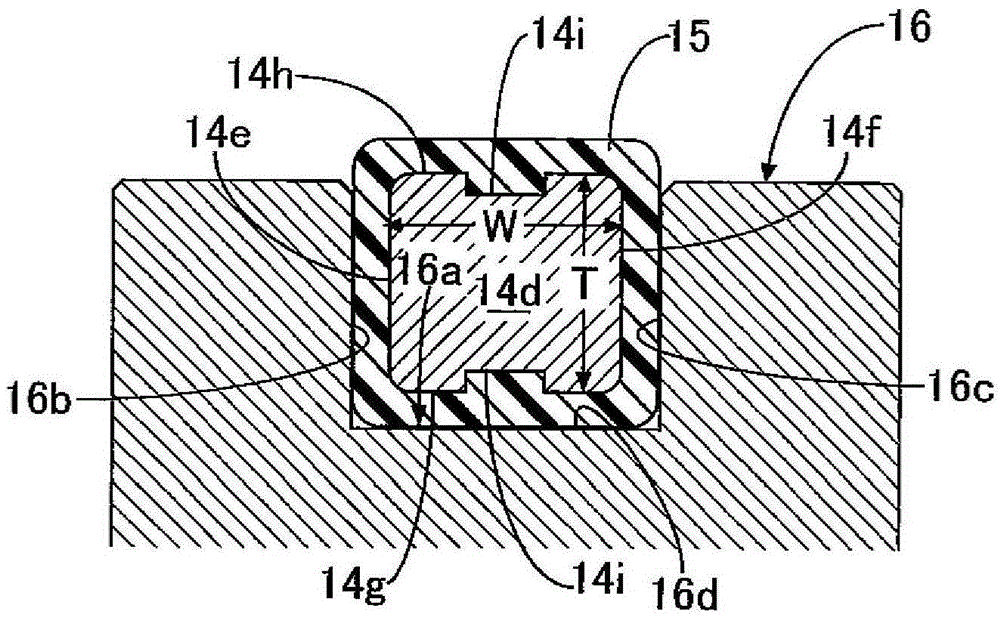

[0039] Such as figure 1 and figure 2 As shown, the shift fork 11 that operates the synchronous device of the motor vehicle transmission includes: a bushing portion 13 that is fixed to the shift fork shaft 12, and the shift fork shaft 12 is connected to the shift lever or the actuator operated by the driver. and a pair of shift fork parts 14, 14 branched from the sleeve part 13 in a double-fork shape. Each shift fork portion 14 is manufactured by punching a metal plate of a fixed thickness into a predetermined shape by shearing and punching, and then bending the first to third bending portions 14a, 14b, and 14c in the thickness direction. It is joined to the boss portion 13 by welding. A wear-resistant resin thin piece 15 is provided at a distal end portion 14d of the shift fork portion 14, and the thin piece 15 is fitted in an annular fork groove 16a formed on an o...

no. 2 Embodiment approach

[0054] Next, based on Figure 5 A second embodiment of the present invention will be described.

[0055] In the first embodiment, the width W of the distal end portion 14d of the shift fork portion 14 is constant, but in the second embodiment, the width W increases toward the distal end side of the distal end portion 14d. As a result, even if the load to remove the sheet 15 from the terminal portion 14d increases, the sheet 15 is less likely to fall off, thereby further improving durability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com