High-strength anchor bolt and production method thereof

A technology for anchoring bolts and production methods, which is applied in the field of metallurgy, can solve the problems that the strength cannot be exceeded, achieve the effects of fast heating speed, fine microstructure, and improved safety reserve capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

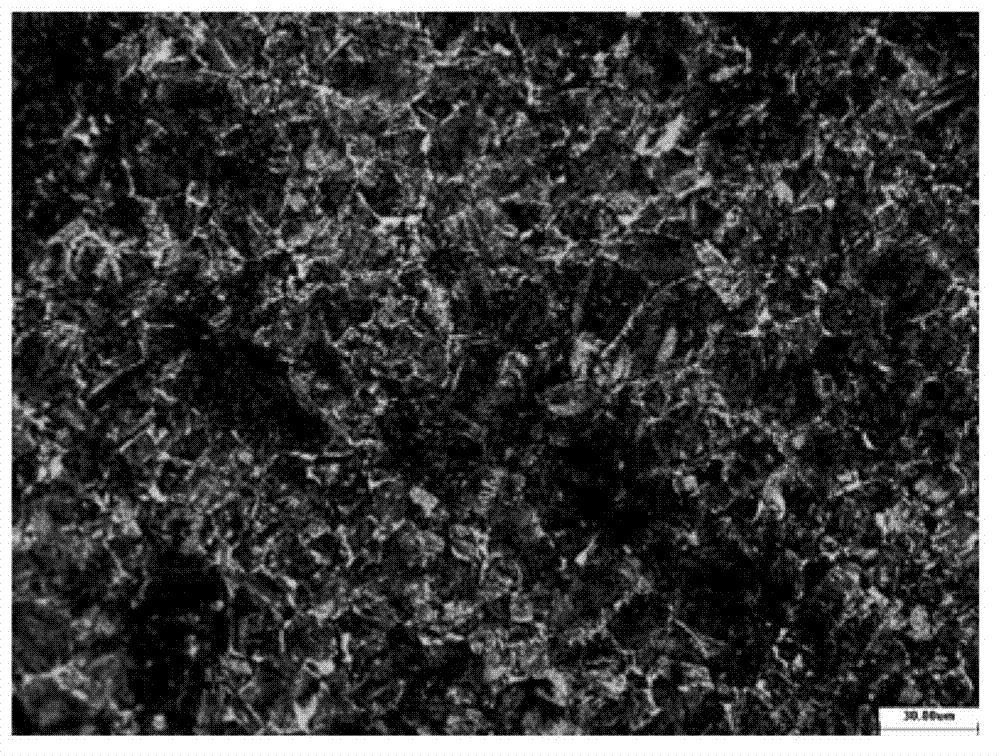

[0034] Utilize the method according to the present invention to prepare high-strength anchor bolts, which include C0.38%, Si0.27%, Mn0.61%, Cr0.88%, and the balance of iron and unavoidable impurities by weight percentage. The high-strength anchor bolts continuously complete feeding, roller conveying, front traction roller, quenching induction heating, quenching cooling, tempering induction heating, tempering cooling, rear traction roller, roller conveying, unloading, etc. on the induction heat treatment production line. Packaging and other production processes. Quenching heating temperature: 820°C, then cooling, tempering heating temperature: 450°C. The yield strength of the steel bar is 1030MPa, the tensile strength is 1165MPa, the elongation A after fracture is 16.0%, the shear strength is 827MPa, and the impact energy at 20°C is 89J.

[0035] figure 1 shows a micrograph of the metallographic structure of the high-strength anchor bolt according to Example 1, according to ...

example 2

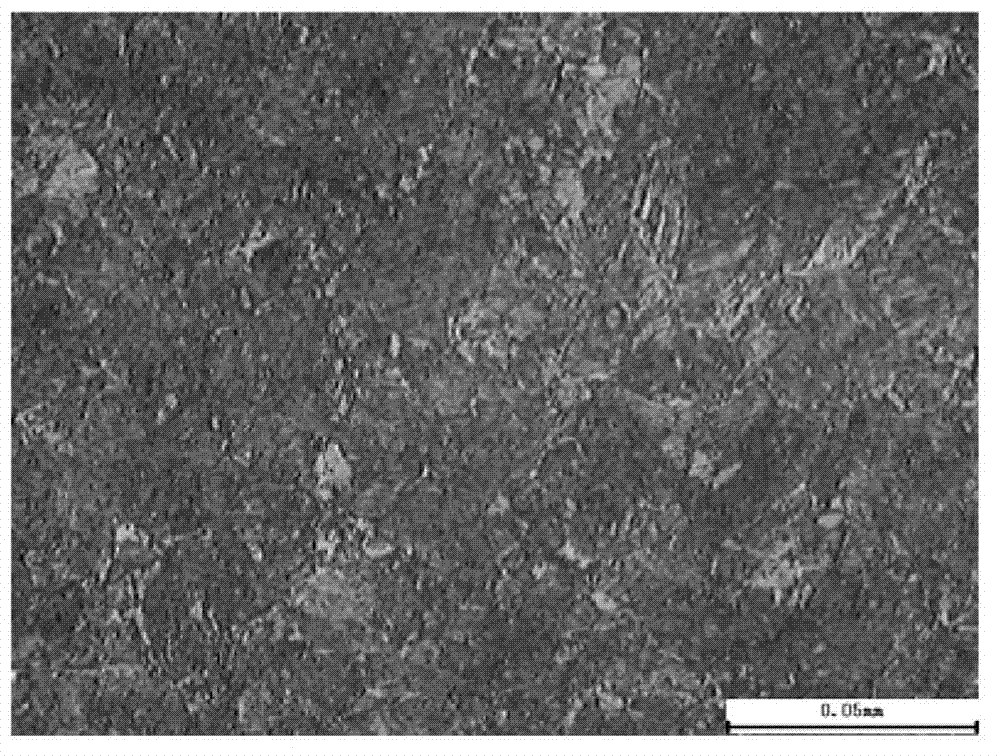

[0037] Utilize the method according to the present invention to prepare high-strength anchor bolts, which include C0.42%, Si0.32%, Mn0.71%, Cr0.98%, and the balance of iron and unavoidable impurities by weight percentage. The high-strength anchor bolts continuously complete feeding, roller conveying, front traction roller, quenching induction heating, quenching cooling, tempering induction heating, tempering cooling, rear traction roller, roller conveying, unloading, etc. on the induction heat treatment production line. Packaging and other production processes. Quenching heating temperature: 780°C, then cooling, tempering heating temperature: 400°C. The yield strength of the steel bar is 860MPa, the tensile strength is 1020MPa, the elongation A after fracture is 18.0%, the shear strength is 719MPa, and the impact energy at 20°C is 109J.

[0038] figure 2 shows a micrograph of the metallographic structure of the high-strength anchor bolt according to Example 2, according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com