Novel anti-explosion grinder

A grinding wheel and grinding wheel technology, which is applied in metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc. The protective cover of the machine does not meet the ergonomic and other problems, and achieves the effect of good operability, increased safety, and reliable safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Since the implementation forms of the barrier position adjustment and fixing mechanism can be various, the specific implementation modes of the present invention are also various. For the convenience of description, this section will be described in the following order:

[0043] A. Vertical and horizontal adjustment methods;

[0044] B. A solution using vertical and horizontal adjustment methods;

[0045] C. Radial and tangential direction adjustment methods;

[0046] D. Overall structure.

[0047] A. Vertical and horizontal direction adjustment implementation

[0048] In this embodiment, the barrier position adjustment mechanism is composed of a longitudinal position adjustment and fixing mechanism and a horizontal position adjustment and fixing mechanism.

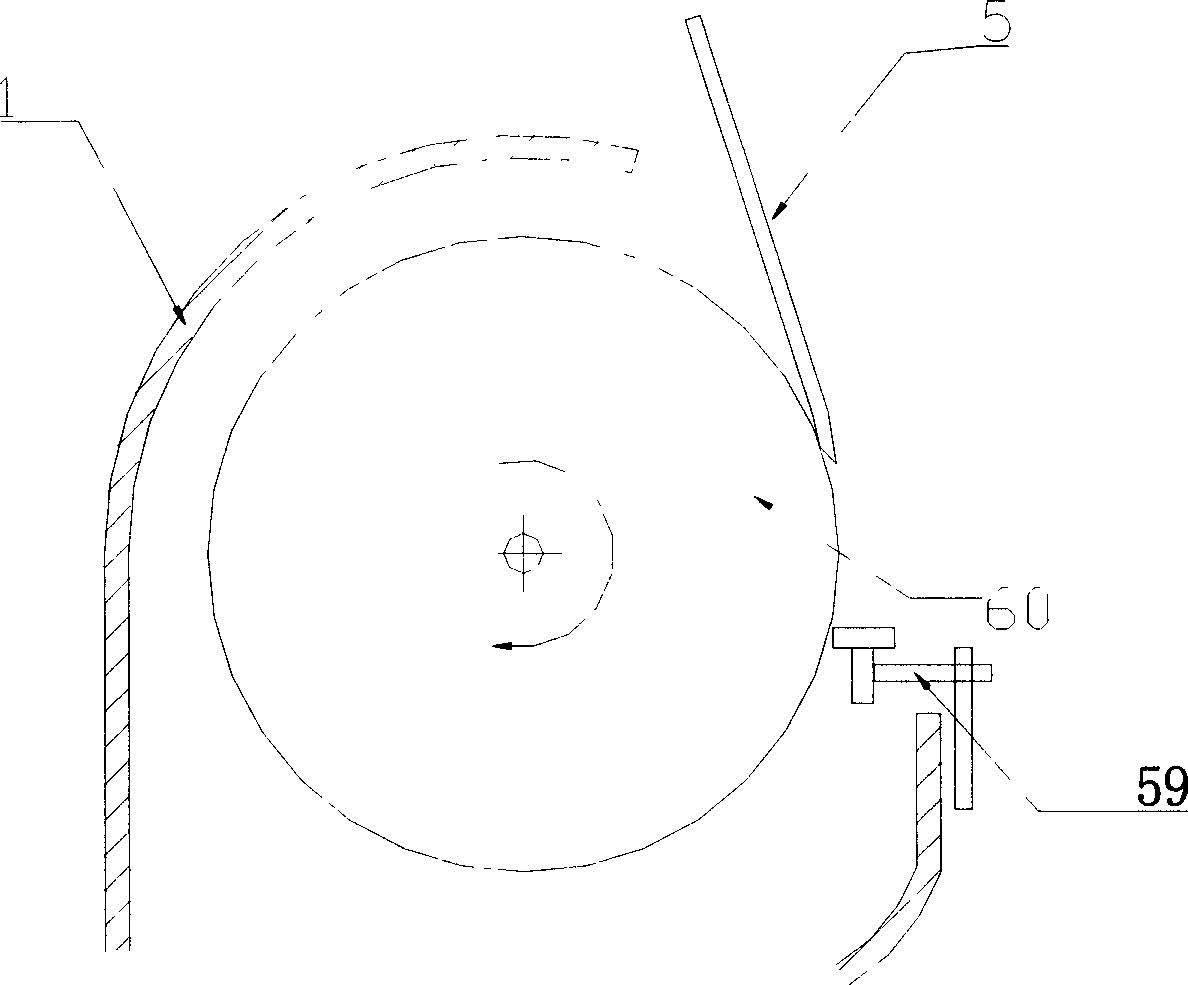

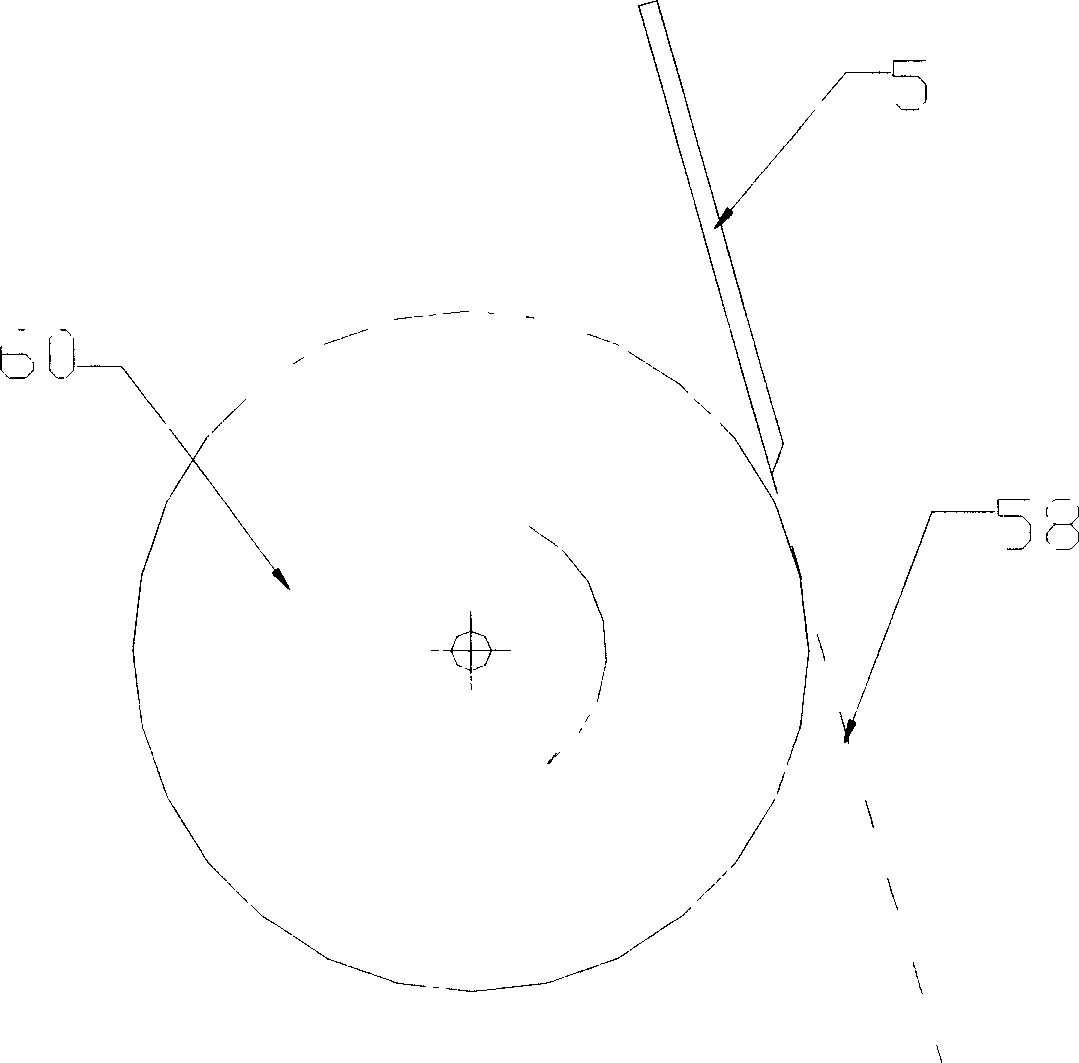

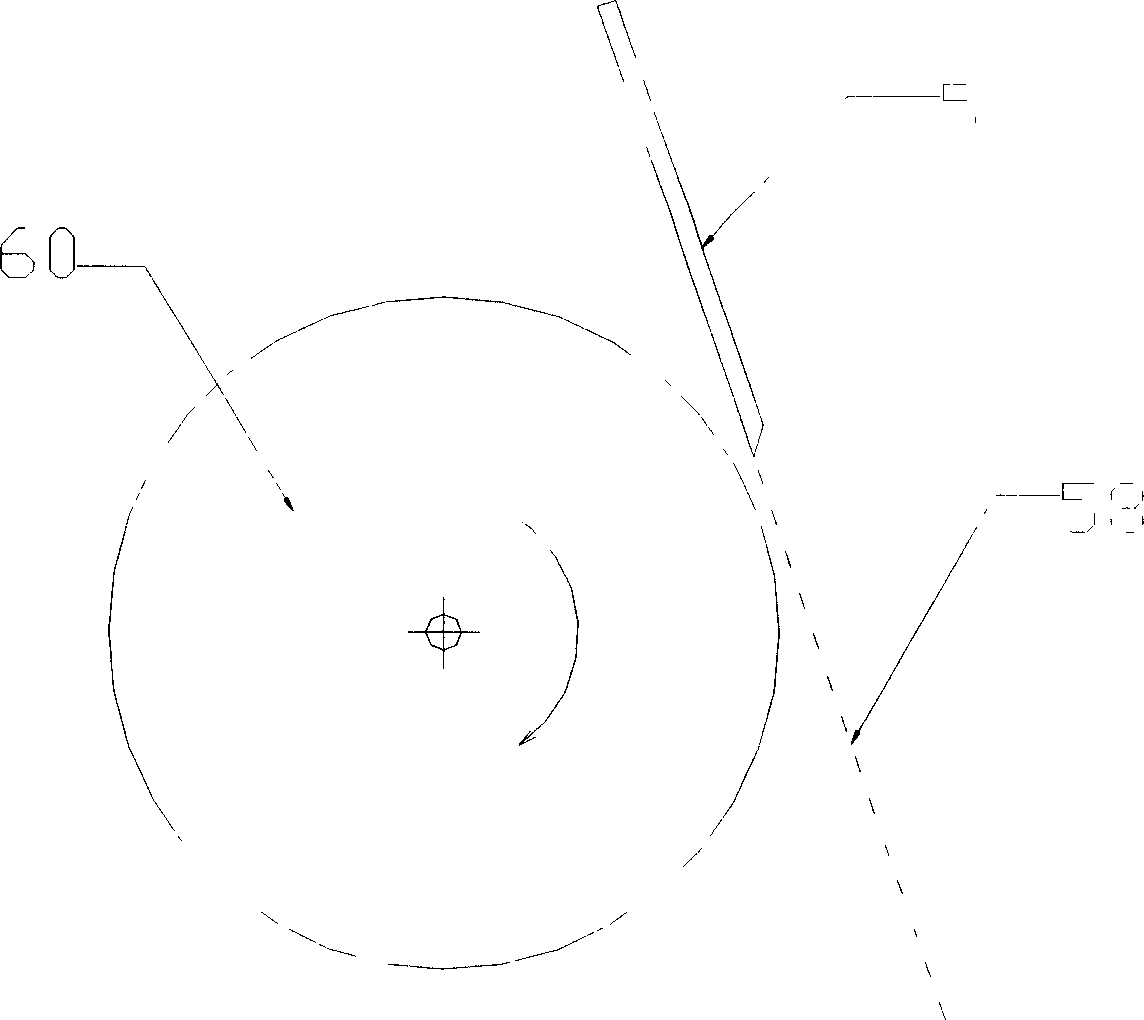

[0049] Figure 5 —— 8 shows a specific example of this embodiment, in which the longitudinal position adjustment mechanism and the horizontal position adjustment mechanism are both gear-rack transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com