Intelligent steel cord butt welding machine and working method thereof

A steel cord and butt welding machine technology, applied in other manufacturing equipment/tools, furnace types, manufacturing tools, etc., can solve problems such as unqualified steel cord solder joints, broken steel cord joints, and user losses. Achieve the effect of improving the success rate and quality of solder joints, smooth and round solder joints, and consistent head shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

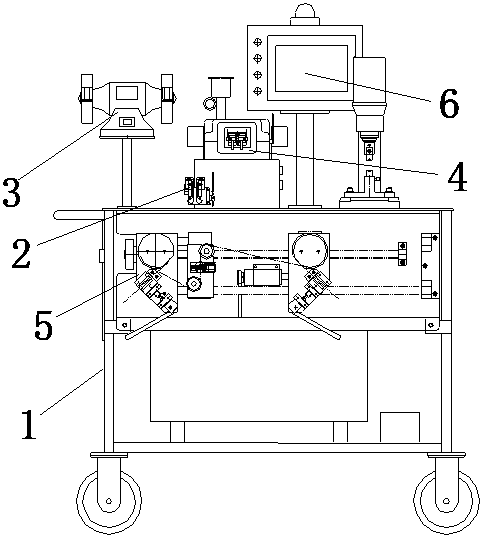

[0038] See Figure 1 to Figure 8 , The present invention relates to an intelligent steel cord butt welding machine, which includes a frame 1, a steel cord welding device 2, a grinding wheel grinding device 3, a welding mechanism 4, an inspection device 5 and a display screen 6. The steel curtain The wire welding device 2, the grinding wheel grinding device 3, the welding mechanism 4 and the display screen 6 are all set on the top of the frame 1, and the inspection device 5 is set in the middle of the frame 1. The steel cord welding device 2 is used to make steel The head of the cord before welding is not loose, the size is uniform, and the head shape is uniform. The grinding device 3 of the grinder passes through the grinding hole on the device to grind away the oxide layer on the surface of the steel cord head due to the welding head to make the steel cord Reliable contact during welding.

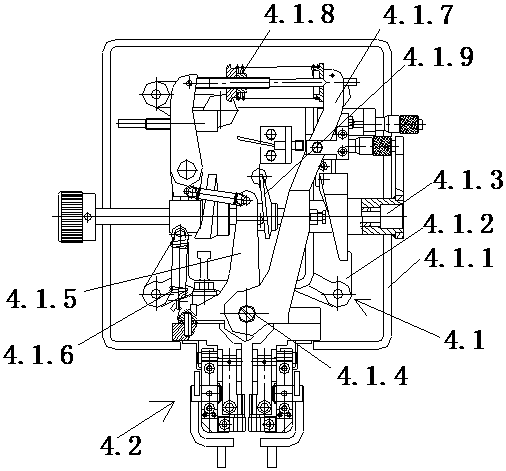

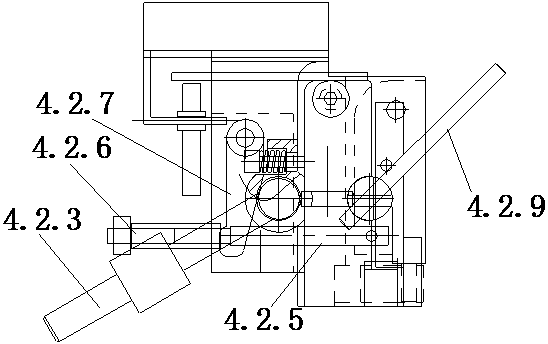

[0039] The welding mechanism 4 includes a mechanism movement part 4.1 and a mechanism fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com