Polishing device for sawtooth on serrated wheel

A serrated wheel and sawtooth technology is applied in the field of processing devices for serrated wheels to achieve the effects of improving work efficiency, ingenious structural design and good practical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

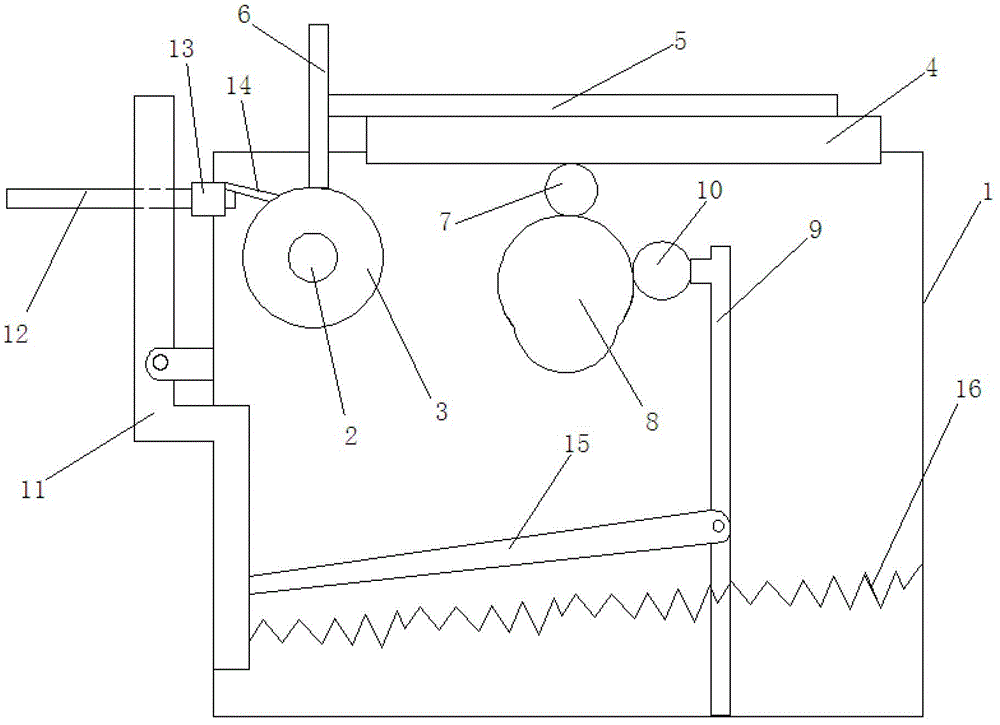

[0015] see figure 1 , a grinding device for saw teeth on a saw gear, comprising a frame 1, a horizontal shaft 2 is fixed on the frame 1, a saw gear 3 is installed on the horizontal shaft 2, and a horizontal support plate 4 is set on the frame 1 , the rotating shaft 5 is installed on the horizontal support plate, and the front end of the rotating shaft is equipped with a grinding wheel 6, and the grinding wheel 6 is pressed against the saw teeth of the saw gear 3 to grind it; the bottom surface of the support plate 4 A runner 7 is installed, and a cam 8 is installed on the frame 1 below the support plate, and the cam 8 rotates 7 against the runner, and the horizontal support plate 4 rotates with the cam 8, Swing down; the frame 1 is provided with a vertical support plate 9 on one side of the cam 8, and the second runner 10 is installed on the vertical support plate 9, and the described cam 8 rotates against the second cam 10, The vertical support 9 plate swings back and forth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com