Drag plate structure of numerical control external cylindrical grinding machine

A cylindrical grinding machine, plate structure technology, applied in the direction of grinding machine parts, grinding drive devices, grinding/polishing equipment, etc. Oil mist, increase maintenance costs and other issues, to achieve the effect of simplifying the structure, improving waterproof performance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

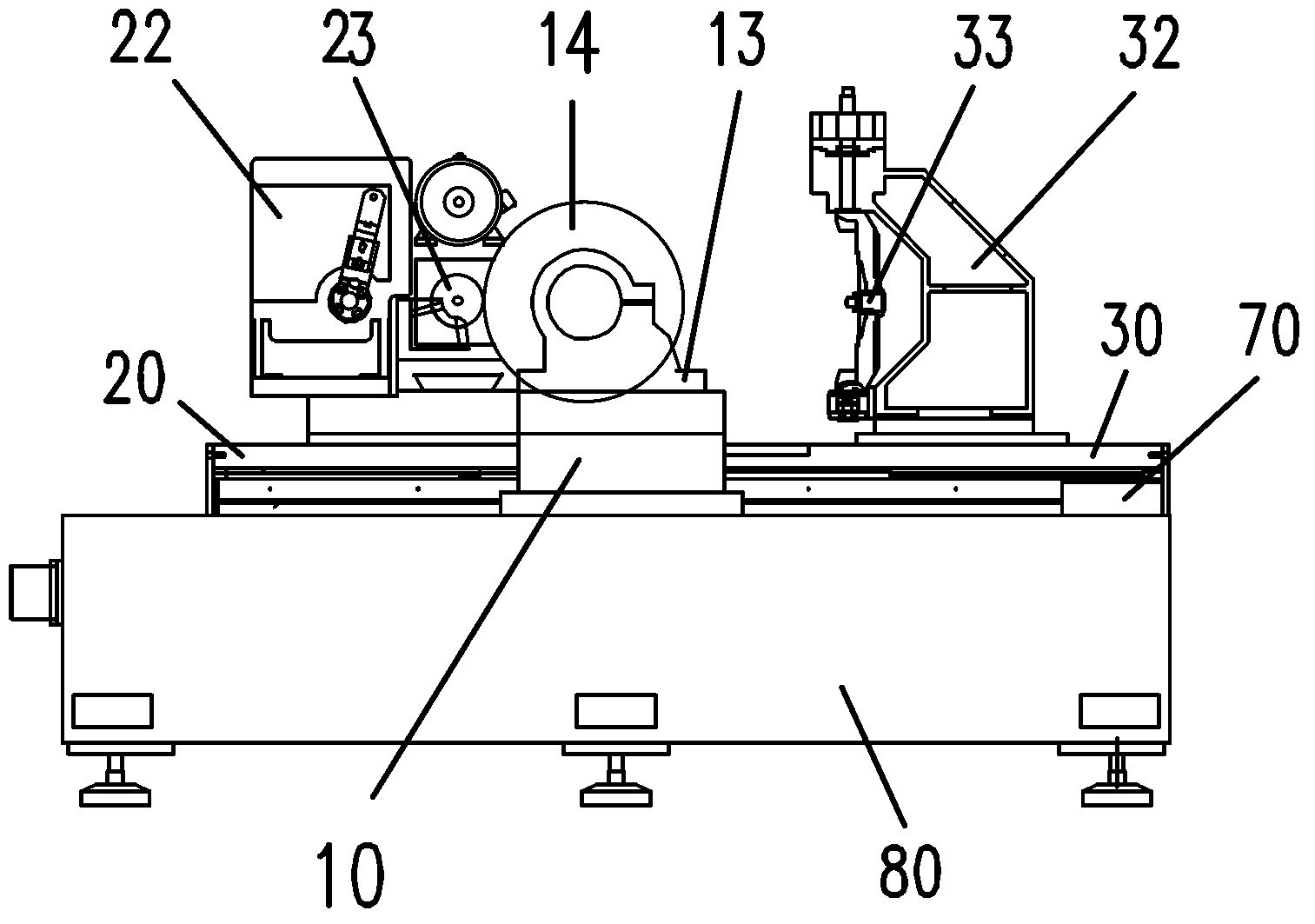

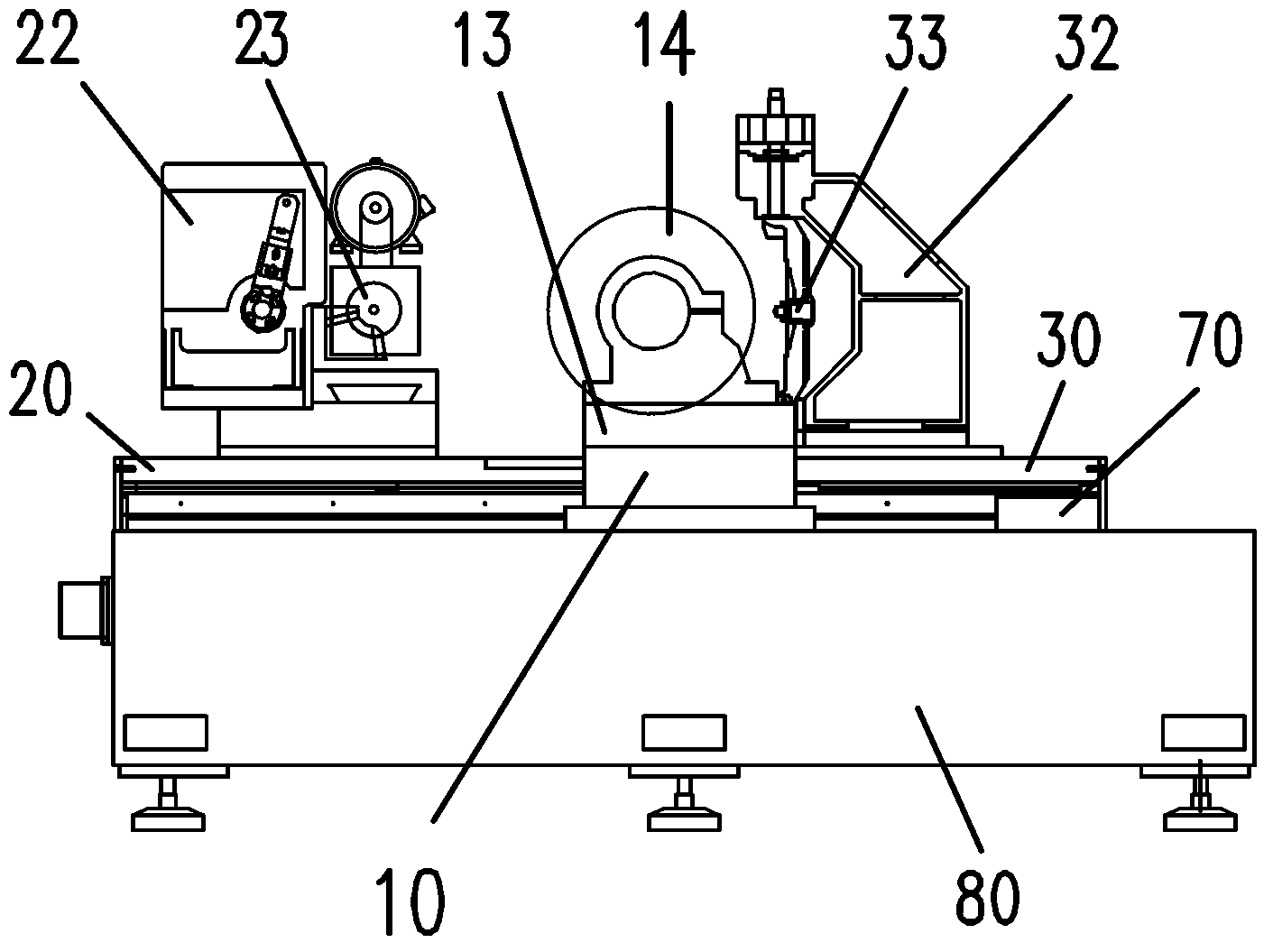

[0026] Such as Figure 1-2 As shown, the carriage structure of a CNC cylindrical grinding machine in the present invention includes a grinder base 10 , a workpiece carriage 20 and a dresser carriage 30 . The grinding wheel base 10 is fixed in the middle of the bed 80, and the workpiece moving mechanism 22 and the grinding wheel dresser 32 are separated on both sides; when the grinding machine is in the grinding state, the workpiece carriage 20 moves to the right, so that the surface of the workpiece 23 gradually approaches the grinding wheel 14, and accepts the grinding wheel. Cut; when the emery wheel surface damages, when needing reconditioning, the reconditioner carriage 30 moves to the left, allows reconditioning knife 33 near emery wheel 14, and emery wheel surface reconditioning is level off.

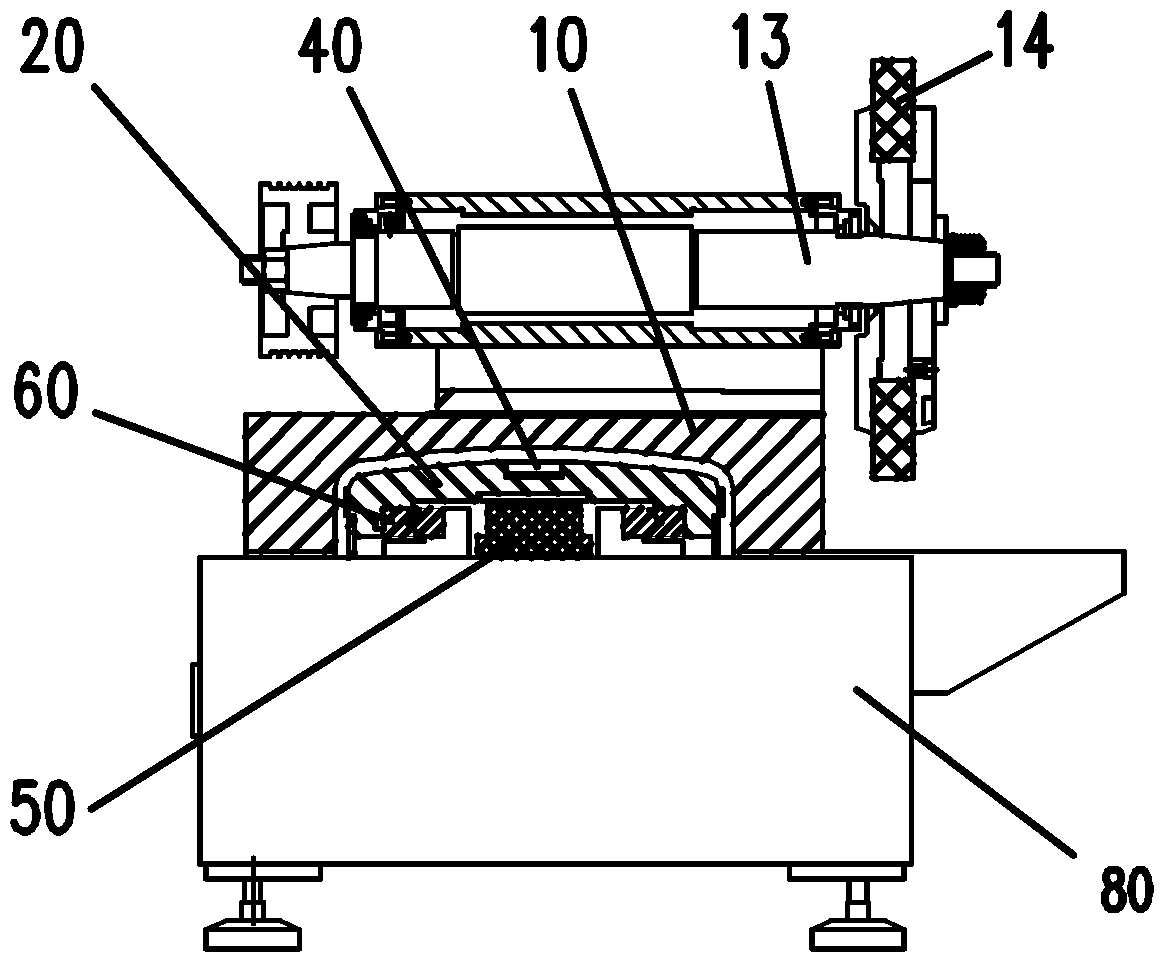

[0027] Such as image 3 As shown, the cross-sectional sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com