Turning tool and planer tool cutter grinding machine

A cutting edge and turning tool technology, applied in the field of cutting edge sharpening equipment, can solve the problems of inability to guarantee the sharpening quality, poor fixture adjustment function, etc., and achieve the effects of light weight, reasonable structure design and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

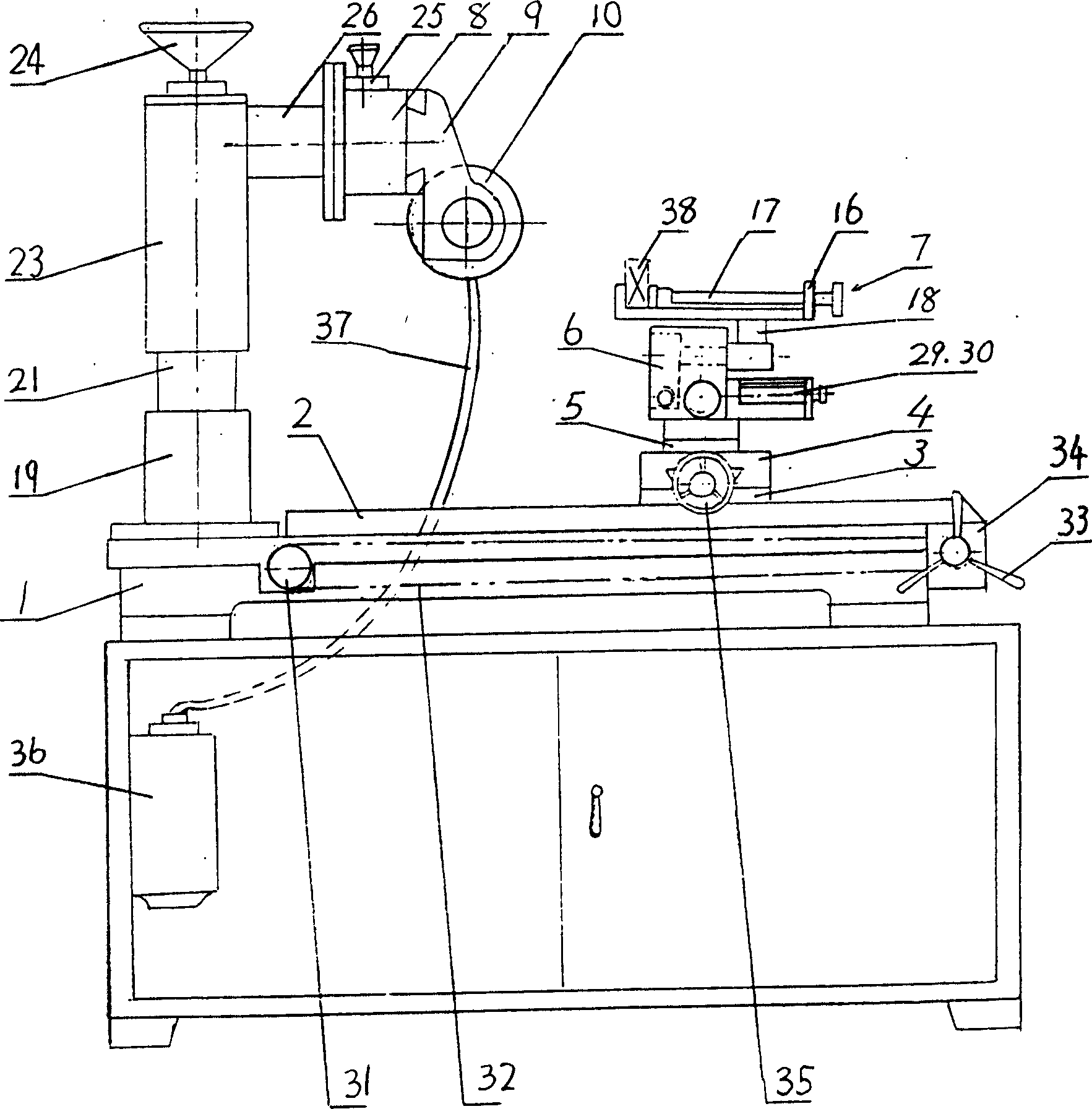

[0019] Such as figure 1 Shown, a kind of turning tool, planer sharpening machine tool comprises: machine base 1, guide rail 2 installed on the machine base, longitudinal carriage 3 positioned on the guide rail, transverse carriage 4 connected with longitudinal carriage dovetail, set The tool head fixture on the horizontal carriage, the grinding wheel device connected with the machine base, and the motor transmission system for driving the grinding wheel.

[0020] The cutter head fixture placed on the horizontal carriage 4 is provided with a universal clamp assembly composed of a longitudinal inclination adjustment mechanism 5 , a transverse inclination adjustment mechanism 6 and a circumferential rotation fixture 7 on the transverse carriage 4 .

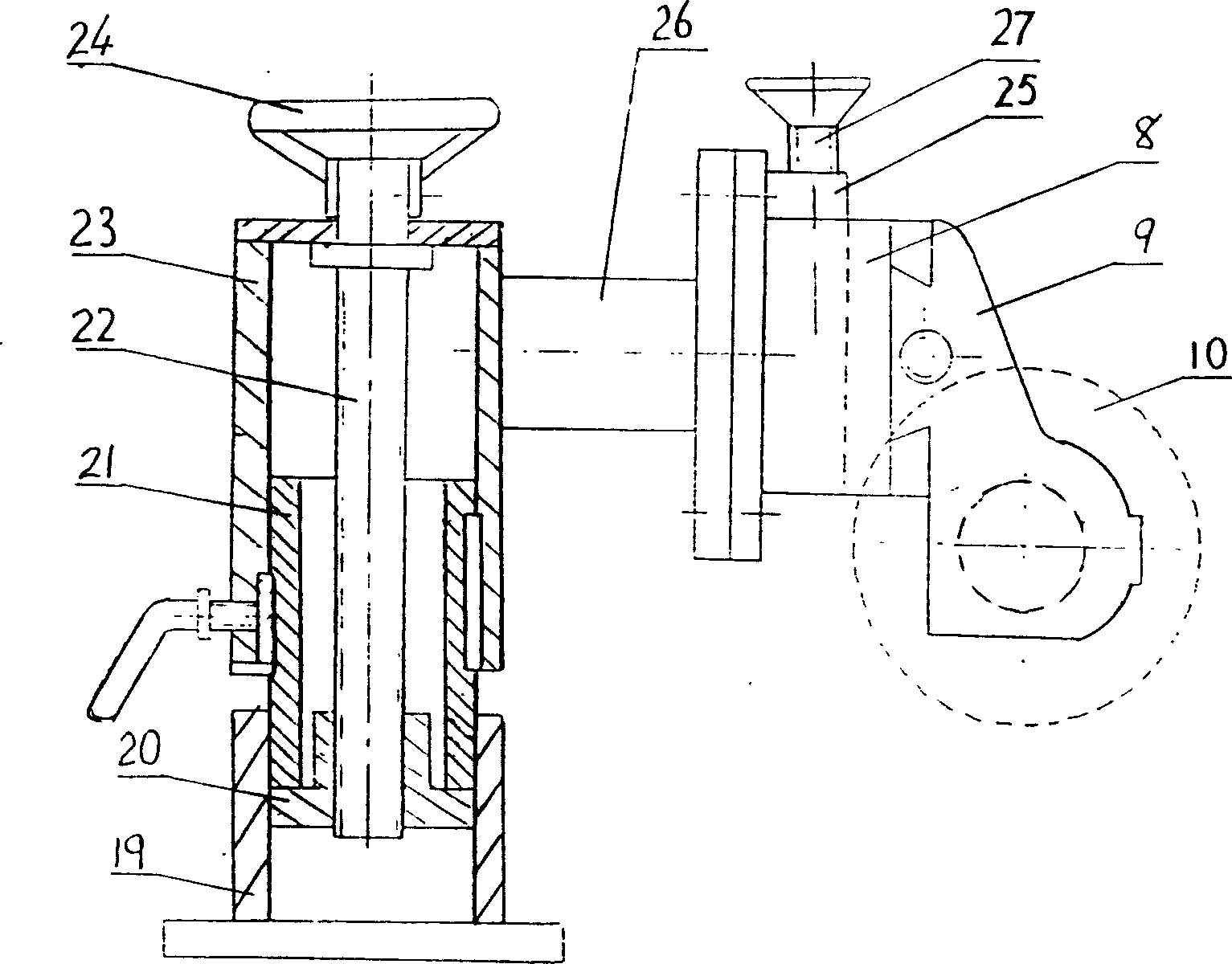

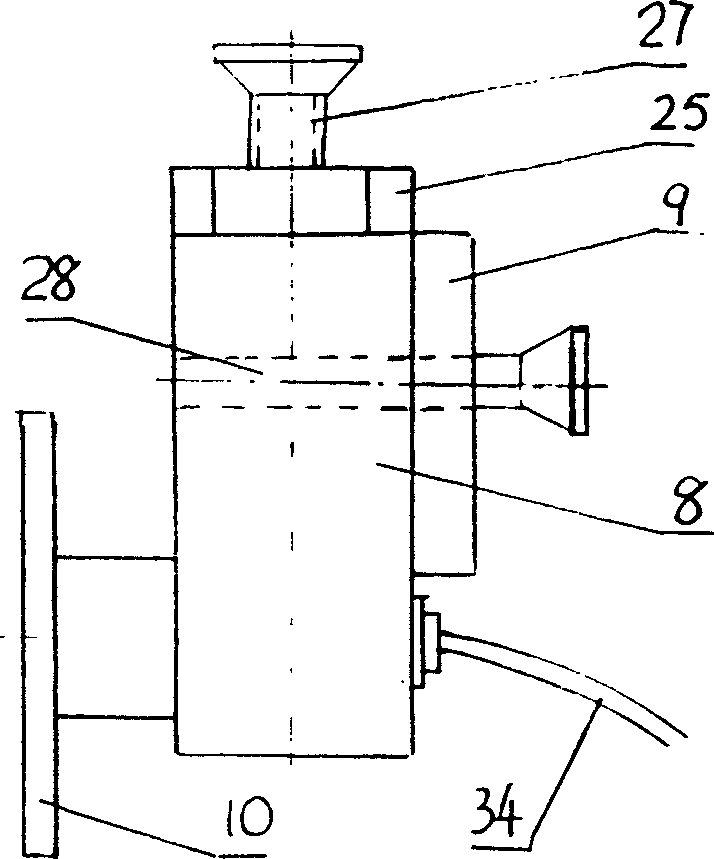

[0021] see figure 2 , the universal clamp assembly, its longitudinal inclination adjustment mechanism 5 is connected with the horizontal carriage 4, and the lateral inclination adjustment mechanism 6 is connected with the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com