A kind of micro-equipment and method for grinding single-crystal diamond micro-blade

A single crystal diamond, micro technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine tool parts, etc., can solve the problem that the order of magnitude of micro-nano parts is not reached, and the micro-edge height of single crystal diamond tools is difficult Processing and other issues, to achieve the effect of compact structure, reduce cumulative error, and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

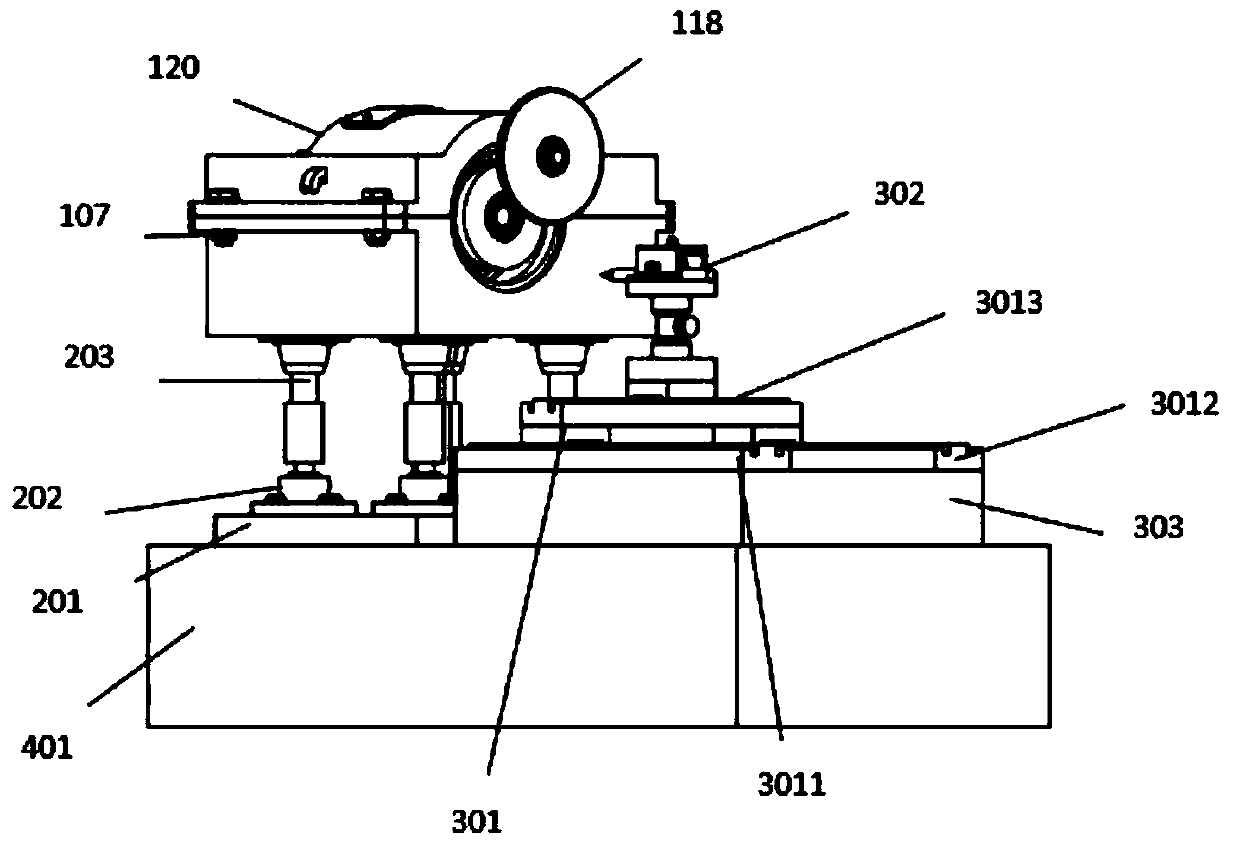

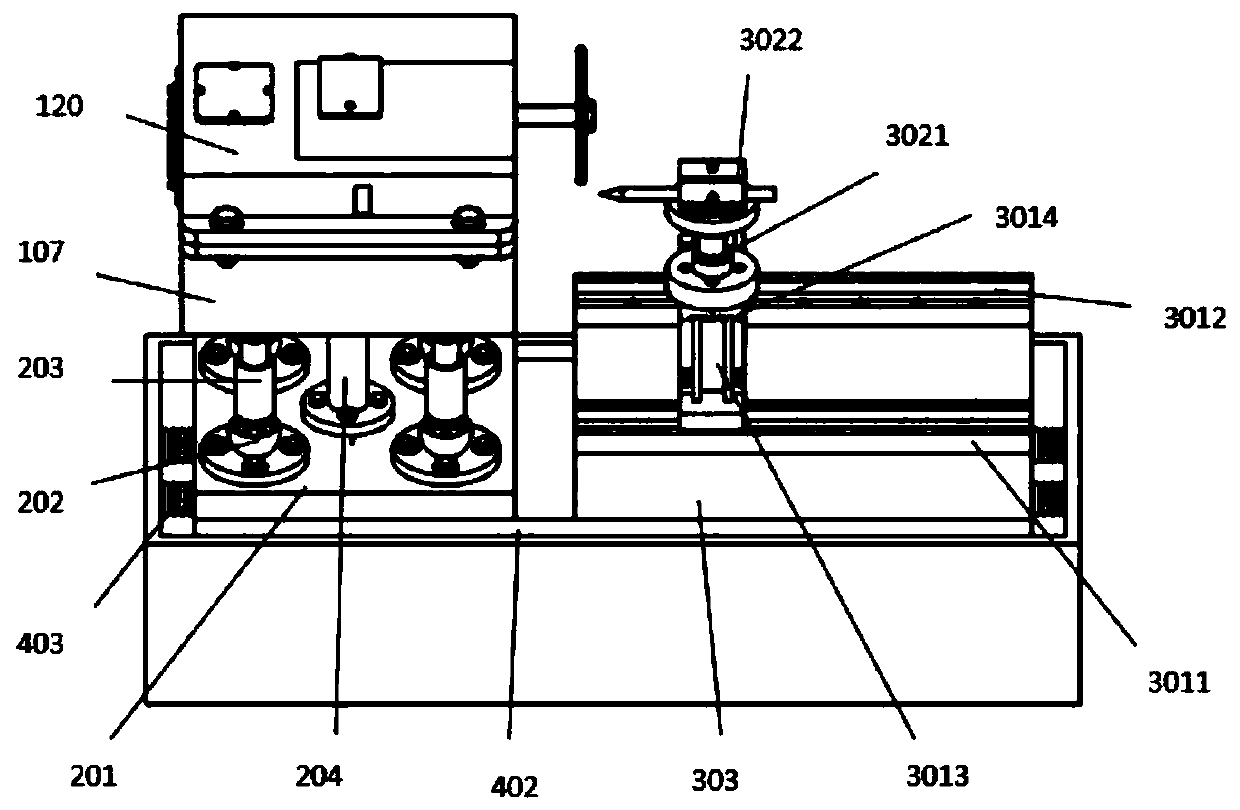

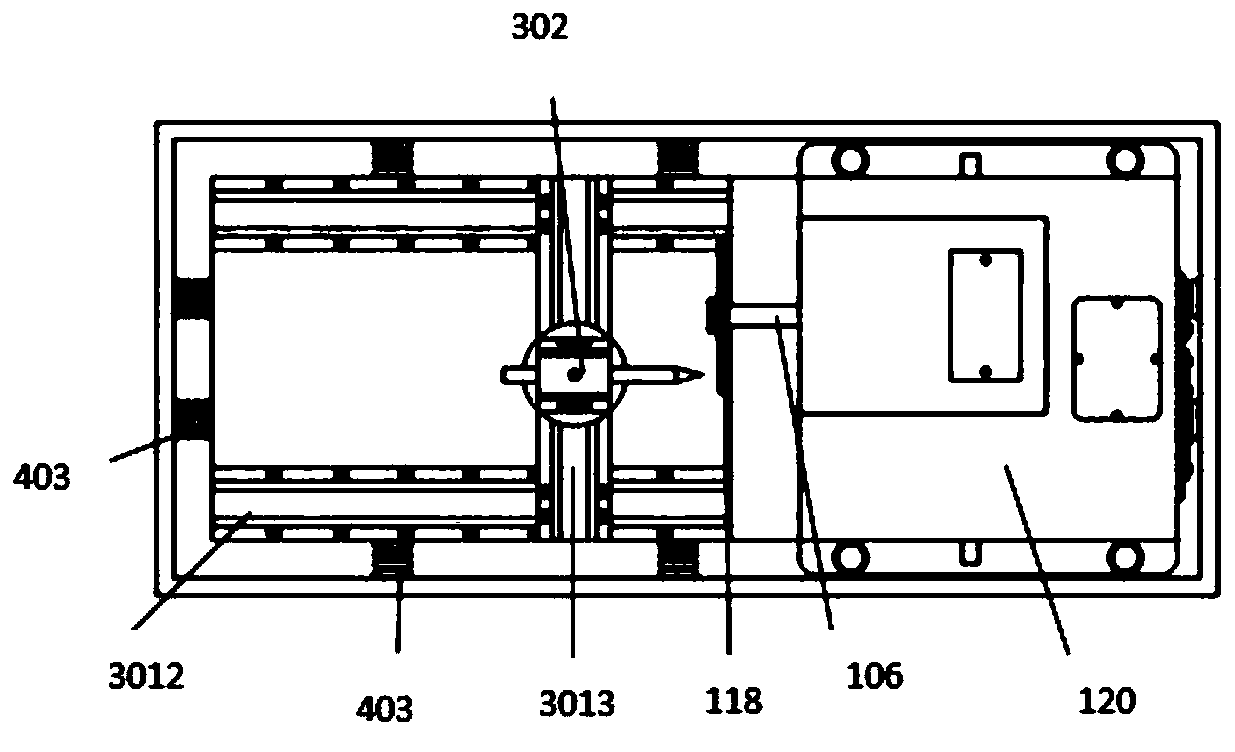

[0064] like Figure 1 to Figure 36 Shown, a kind of micro-equipment for grinding single-crystal diamond micro-blade includes workpiece feeding device 3 and bush shaft drive feeding device 1.

[0065] The workpiece feeding device 3 includes a clamp 302 and a driving device that drives the clamp 302 to move horizontally and vertically. The single crystal diamond to be processed is clamped on the clamp 302 .

[0066] The clamp 302 includes a clamp support platform 3021 and a clamp body 3022 arranged above the clamp support platform 3021. The clamp body 3022 is in the shape of a few characters. The inside of the clamp body 3022 is provided with two oppositely arranged spring plates 3023. The two spring plates 3023 Cooperate between them to form a clamping gap for the single c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com