Gear chamfering device

A chamfering and equipment technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve problems such as low machining accuracy, accidental damage, uneven force and angle control, etc., to achieve high processing quality and ensure cleanliness , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be further described in detail below.

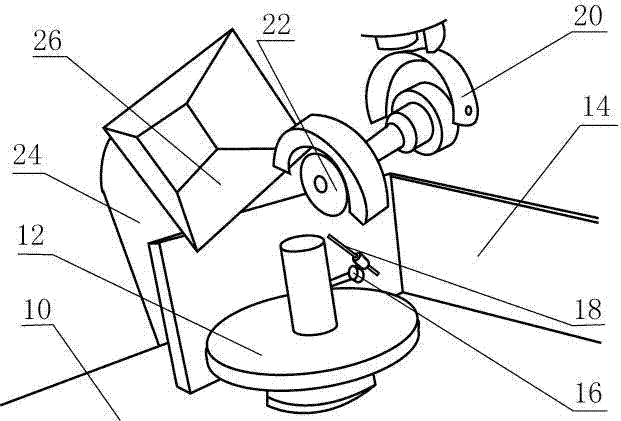

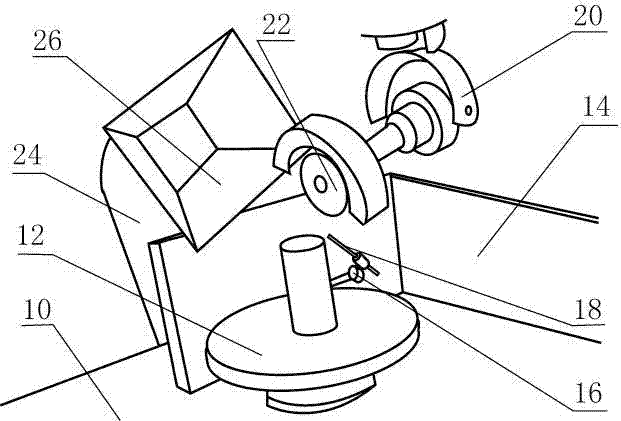

[0013] Such as figure 1 As shown, a gear chamfering equipment of the present invention includes a workbench 10 on which a workpiece support 12 is arranged. The workpiece support 12 of the first embodiment of the present invention is a round table, which can rotate horizontally under the drive of a motor (not shown). The workpiece support 12 is provided with a semi-enclosed baffle plate 14 perpendicular to the workbench 10. In the first embodiment of the present invention, three adjacent baffle plates 14 are used to surround the two sides and the back of the workpiece support 12 respectively. The workpiece support 12 is provided with a fixed rod support 16, the fixed rod support 16 is pivotally connected with a metal rod-shaped fixed rod 18, and the fixed rod 18 is passed through a fastening bolt (not shown) shown), the fixing rod 18 can be fixed. A grinding wheel support 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com