Blade grinding machine

A blade and grinding machine technology, applied in the direction of grinding machine parts, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of waste of resources and high costs, and achieve the effect of avoiding waste of resources and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

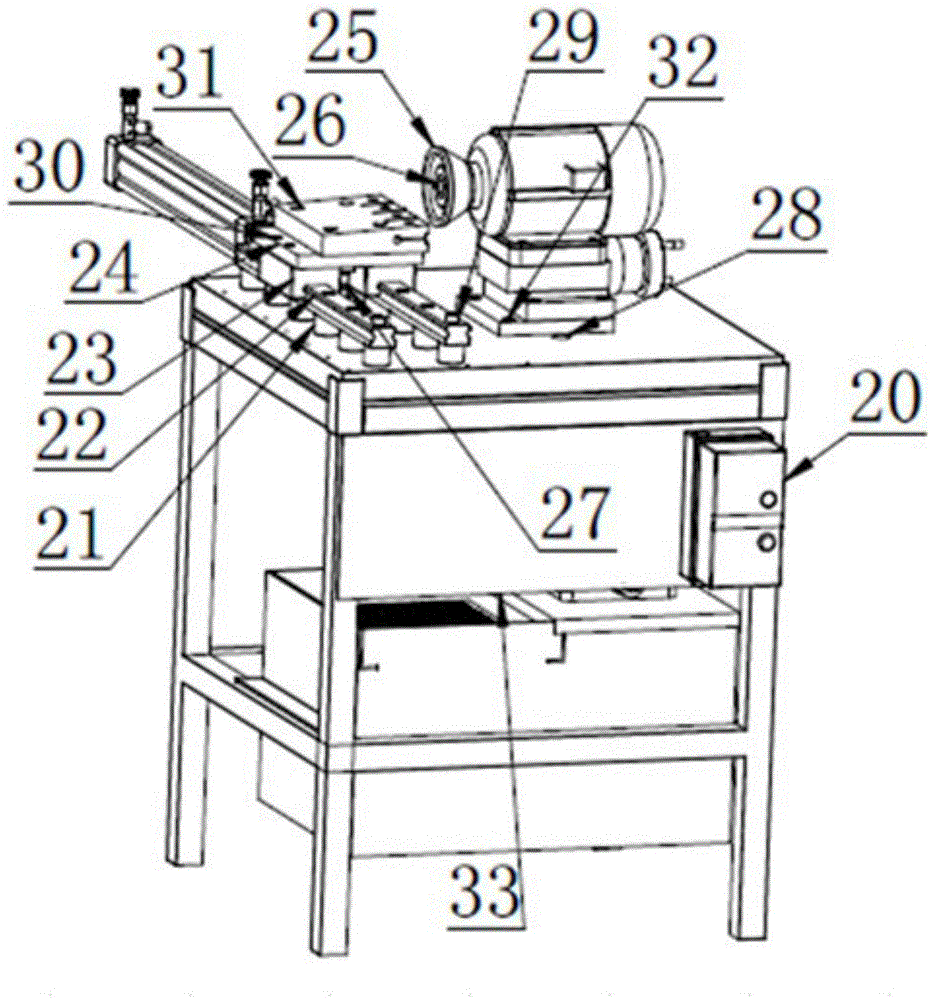

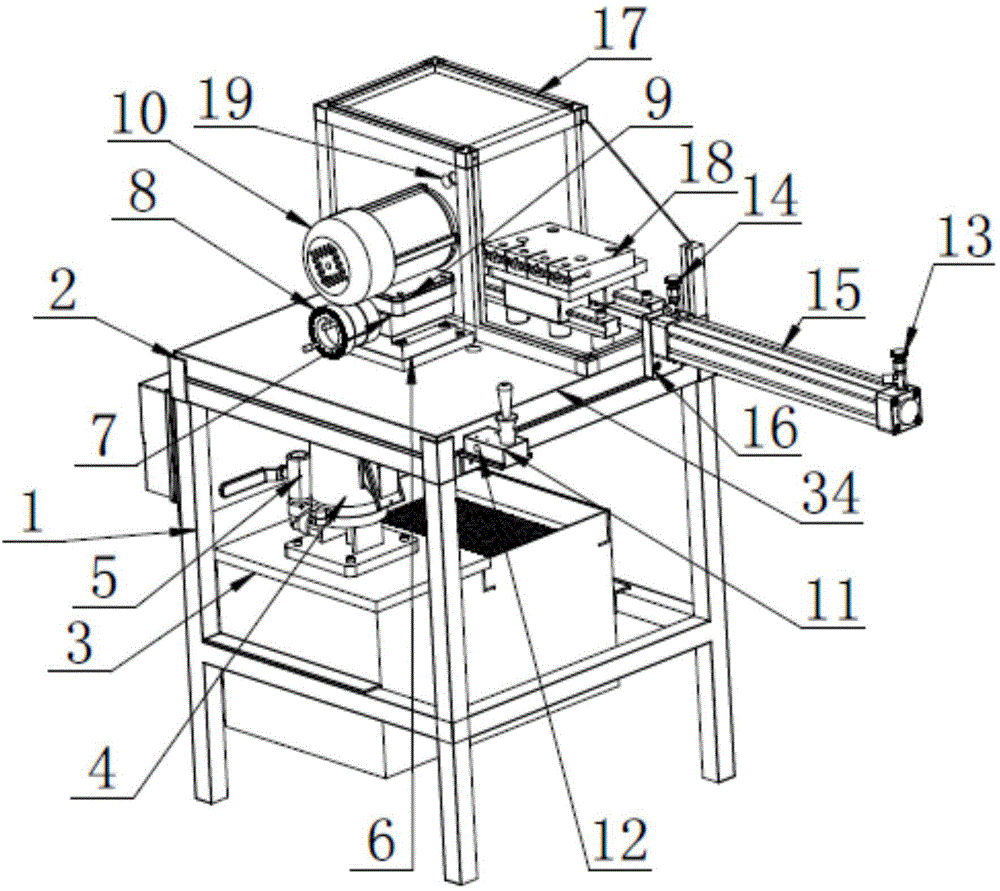

[0017] Such as figure 1 — figure 2 As shown, the present invention comprises: a support 1, the bottom of the support 1 is provided with a crossbeam for supporting the cooling water tank 3, and a pumping motor 4 is fixed on the cooling liquid water tank 3; A support base plate 34 is arranged above the beam, and a layer of leather pad is added between the support base plate 34 and the support 1 to reduce the vibration brought to the support 1 when the machine is working; a power switch is installed on the side plate 33 of the support 1 20, the power switch 20 is connected with the control water tank motor 4 and the grinding wheel motor 10 respectively, and is used for the power switch 20 to control the water tank motor 4 and the grinding wheel motor 10 to start and close; a slide table 7 and two slides are installed on the support base plate 34 of the bracket 1 Line rails 22 arranged in parallel and a cylinder 15 connected to the air source control valve 11; wherein, a spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com