Grinding machine

A grinding wheel and bolt technology, applied in the field of grinding machines, can solve the problems of poor safety performance, troublesome use, inability to grind, etc., and achieve the effect of safe use

Inactive Publication Date: 2013-02-20

SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the grinding wheel machine is generally composed of the grinding head of the grinding wheel machine installed and fixed on the base. When grinding the workpiece, the workpiece is generally held in hand and directly contacts the grinding wheel of the grinding wheel grinding head. Therefore, there are defects such as troublesome use and poor safety performance. , in particular, it is impossible to perform more precise grinding on workpieces that require a certain thickness.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

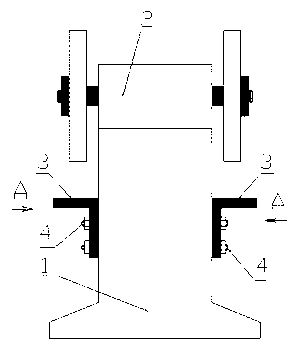

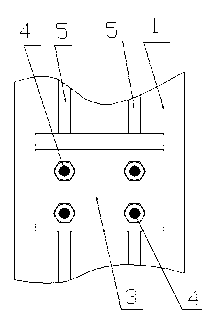

[0010] A grinder, comprising: grinder head (1), base (2), right-angle bent plate (3), T-shaped head bolts (4), characterized in that: the grinder head (1) is installed and fixed on On the top of the base (2), vertical T-slots (5) are made on both sides of the grinder base (2), and T-head bolts ( 4), the right-angle bent plate (3) is installed and fixed on both sides of the base (2) through T-head bolts (4).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A grinding machine is characterized in that on the basis of an existing grinding machine structure, vertical T type grooves are arranged on two sides of a grinding machine base, T type cap bolts are arranged in the T type grooves arranged on two sides of the base, and right angle bended plates are fixed at two sides of the bases through the T type cap bolts. By means of the technical scheme, during workpiece grinding, workpieces can be supported onto the right angle bended plates, simultaneously, in grinding workpieces with specific thicknesses, only the upper planes of the right angle bended plates are required to be adjusted to a specific distance at the downmost end of a grinding wheel, and placing the workpieces between the grinding wheel and the right angle bended plates. Therefore, the grinding machine has the advantages of being safe in use and convenient and in particular has accurate grinding on the workpieces with certain thickness.

Description

technical field [0001] The invention relates to a grinder and belongs to the technical field of electromechanical equipment. Background technique [0002] At present, the grinding wheel machine is generally composed of the grinding head of the grinding wheel machine installed and fixed on the base. When grinding the workpiece, the workpiece is generally held in hand and directly contacts the grinding wheel of the grinding wheel grinding head. Therefore, there are defects such as troublesome use and poor safety performance. , in particular, it is impossible to perform more accurate grinding on workpieces that require a certain thickness. Contents of the invention [0003] The purpose of the present invention is to provide a new type of grinder aiming at the above-mentioned defects existing in the existing grinder. The above-mentioned defects existing in the existing grinder are overcome. [0004] The technical solution adopted by the present invention to achie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B27/00

Inventor 孙生强

Owner SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com