Linear big-chamfer glass edge grinding machine

An edge grinding machine and glass technology, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems of small angle variation range, low edge grinding efficiency, inconvenient operation, etc. The effect of high price, reliable processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

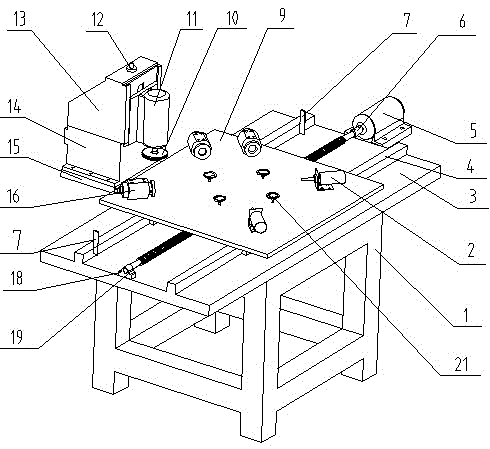

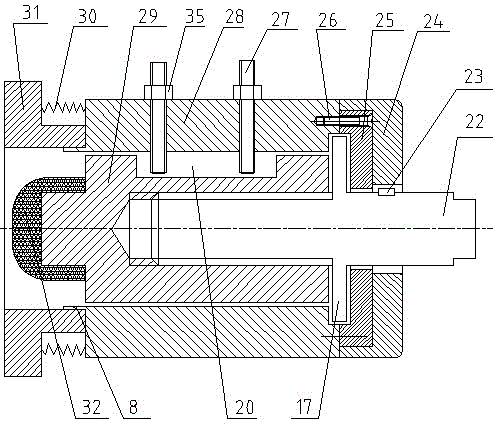

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the linear large chamfering glass edging machine of the present invention includes a frame 1, a feed drive motor 5 arranged on the frame 1, a longitudinal guide rail 4 arranged on the frame 1, and a longitudinal guide rail 4 slidingly connected On the workbench 9, the power output end of the feed drive motor 5 is connected to the feed screw 19 parallel to the longitudinal guide rail 4, the feed screw 19 is screwed to the bottom of the workbench 9, and one part of the longitudinal guide rail 4 An edge grinding device is provided on the side, and a glass support block 21 and a positioning and clamping device positioned around the glass support block 21 are provided on the workbench 9 .

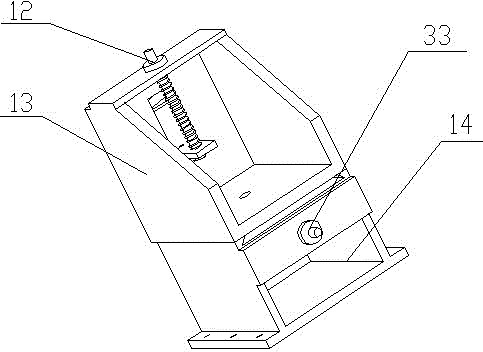

[0019] The edging devices all include a fixed frame 14, a movable frame 13, an emery wheel drive motor 11 and an edging emery wheel 10 arranged on the frame 1, and the movable frame 13 is slidably connected to the fixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com