Grinding cloth wheel and manufacturing method of grinding cloth wheel

A manufacturing method and technology for abrasive cloth wheels, which are applied in the field of abrasive cloth wheels, can solve the problems of inconvenient operation and use, uneven force application, inaccessibility, etc., and achieve the effects of high grinding efficiency, ensuring flatness and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

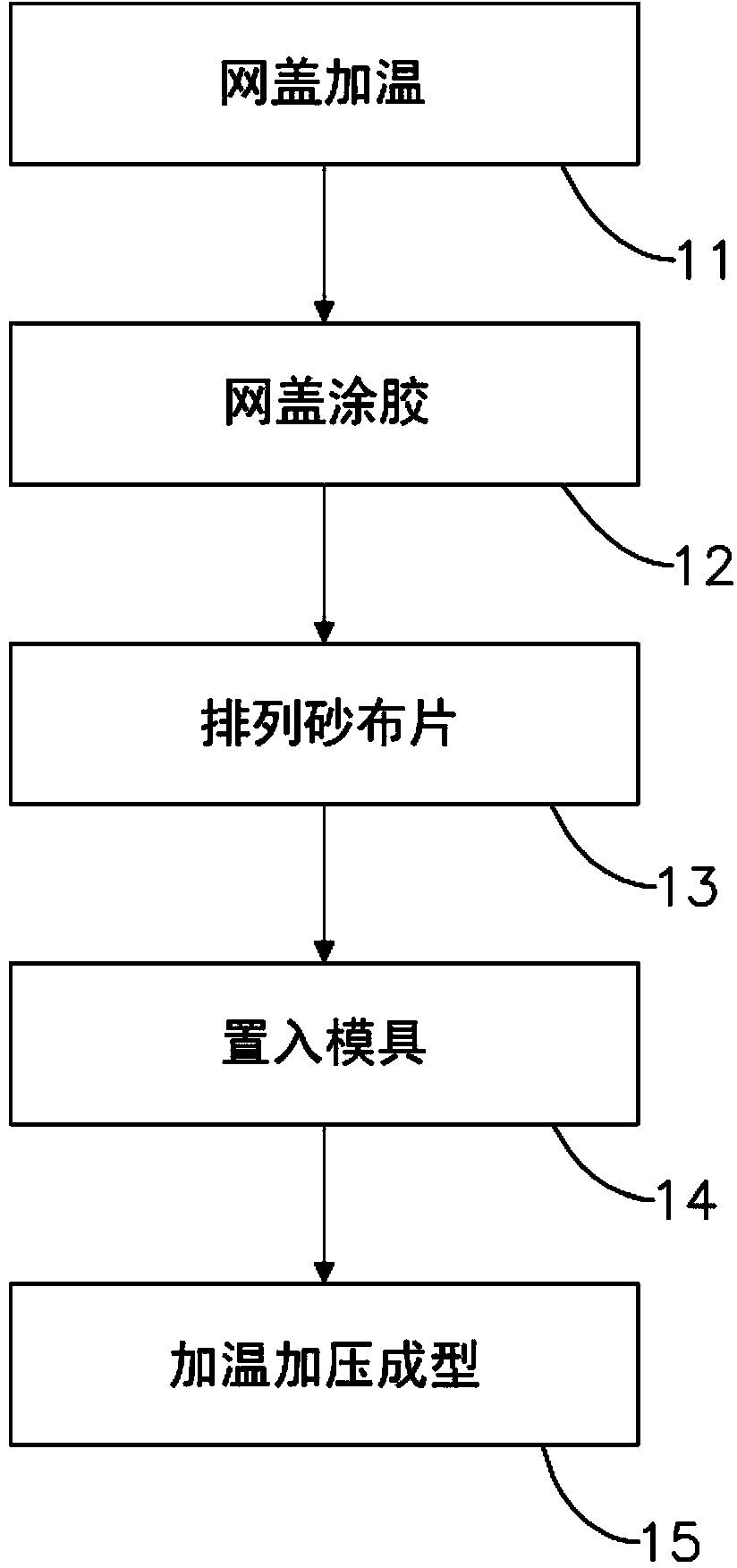

[0061] see figure 1 As shown, the manufacturing method of the emery cloth wheel of the present invention comprises a net cover heating step 11, a net cover gluing step 12, an arranging emery cloth sheet step 13, an inserting mold step 14 and a heating and pressing forming step 15 .

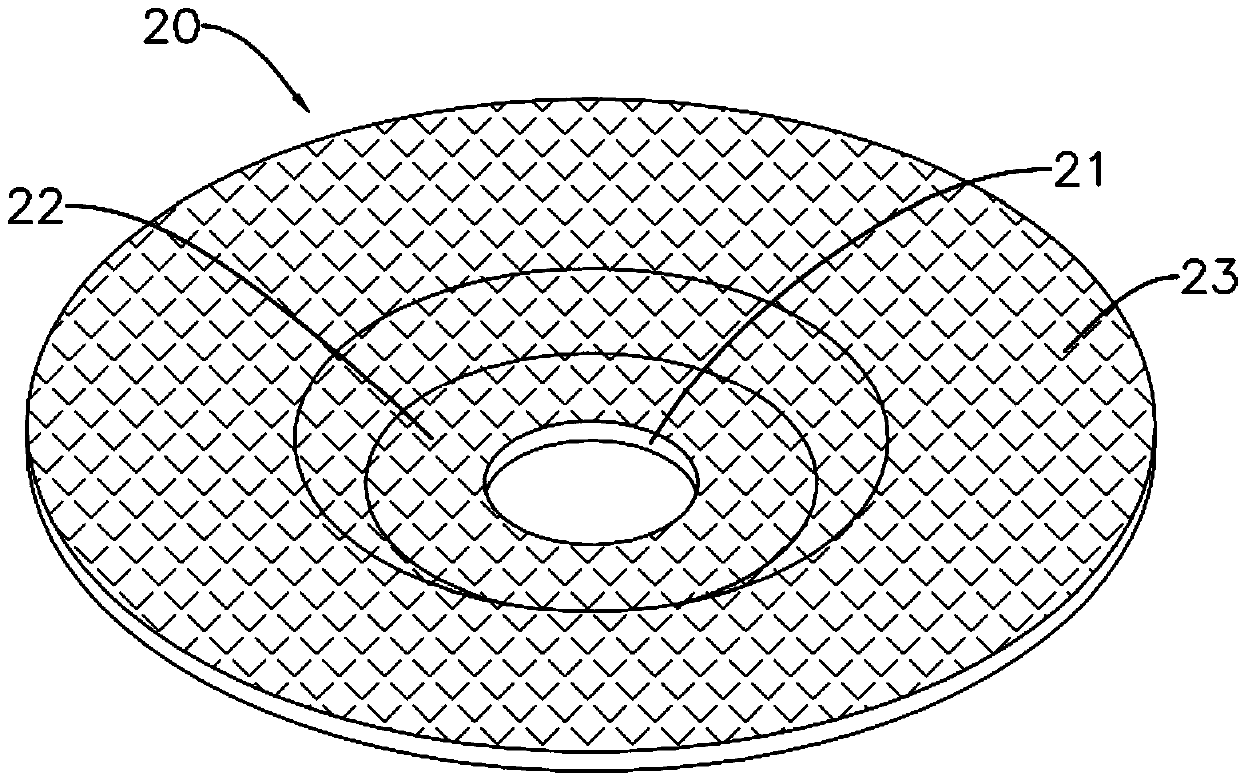

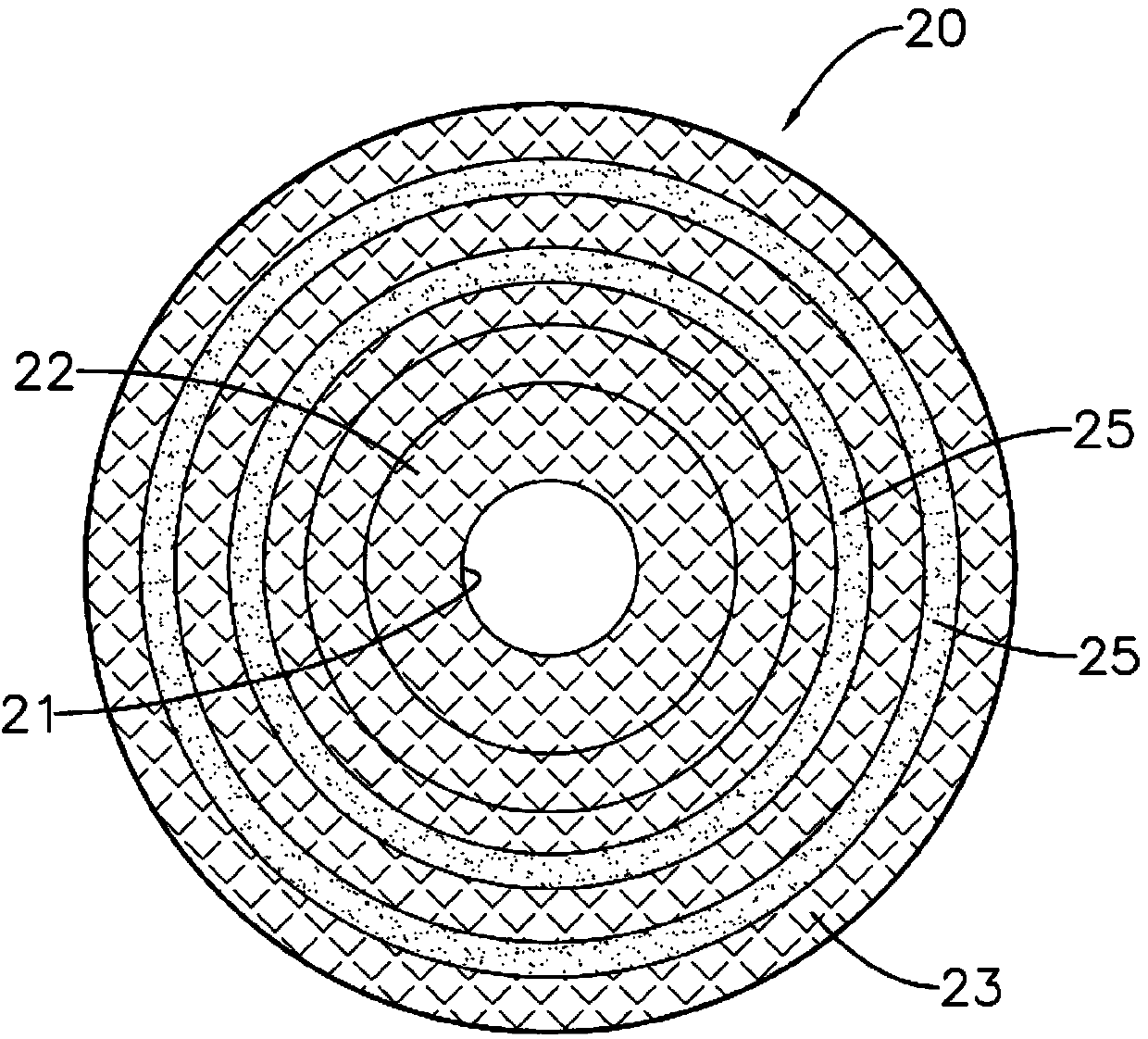

[0062] see further figure 2 As shown, in the net cover heating step 11, a net cover 20 is placed in a first heating device and heated to 40°C to 50°C, and the heating is continued for 30 minutes to 40 minutes, so that the net Cover 20 softens. Wherein, the net cover 20 is in the shape of a disc, and a shaft hole 21 is formed through the center of the net cover 20. The net cover 20 has an annular concave portion 22 and a fitting portion 23, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com