Steel bar cutting machine with dust removing and counting functions

A cutting machine and steel bar technology, applied in the direction of counting mechanism/items, manufacturing tools, chemical instruments and methods, etc., can solve problems such as safety issues, environment, human body injury of cutting machines, cost increase, etc., to ensure health problems and improve Safety and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

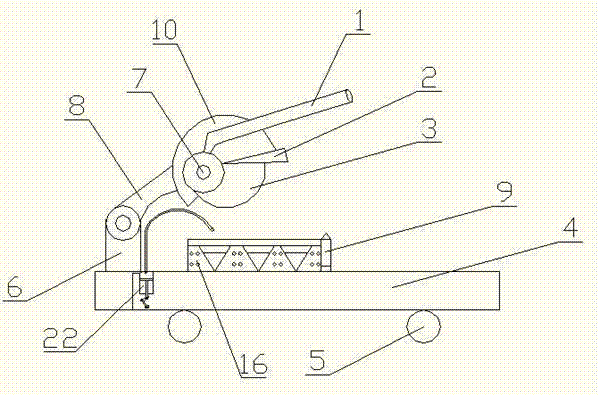

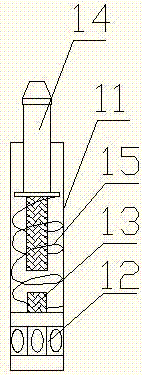

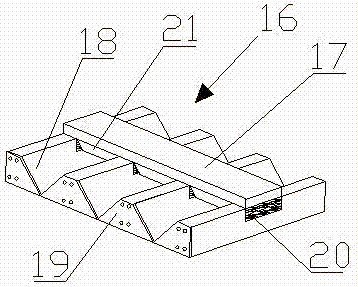

[0014] Example. A steel cutting machine with dust removal and counting functions, constituted as Figure 1-Figure 5 Shown, comprise base 4, be provided with support arm 6 on base 4, be connected with mobile arm 8 on support arm 6, movably connect between support arm 6 and mobile arm 8, machine cover 10 is installed on the top of mobile arm 8, machine cover A first motor 7 is installed in the 10, and the first motor 7 is connected with a grinding wheel 3; the outside of the machine cover 10 is connected with a handle 1; the base 4 is also provided with a counting device 9 and a clamping device 16; the counting device 9 is provided with Right below the handle 1, the handle 1 moves downward to touch the counting device 9; the counting device 9 includes a casing 11, and a counter 12 is arranged in the casing 11, and the counter 12 is connected with a counter trigger button 13, and the counter trigger button 13 is provided with a contact 14, the outside of the contact 14 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com