Shaft, particularly a cam shaft, comprising a hollow shaft section

A technology for hollow shafts and camshafts, which is applied to shafts including hollow shaft sections, especially in the field of camshafts, which can solve the problems of incomplete anti-splashing and structural space consumption of pre-separators, and achieve the goal of preventing oil intrusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

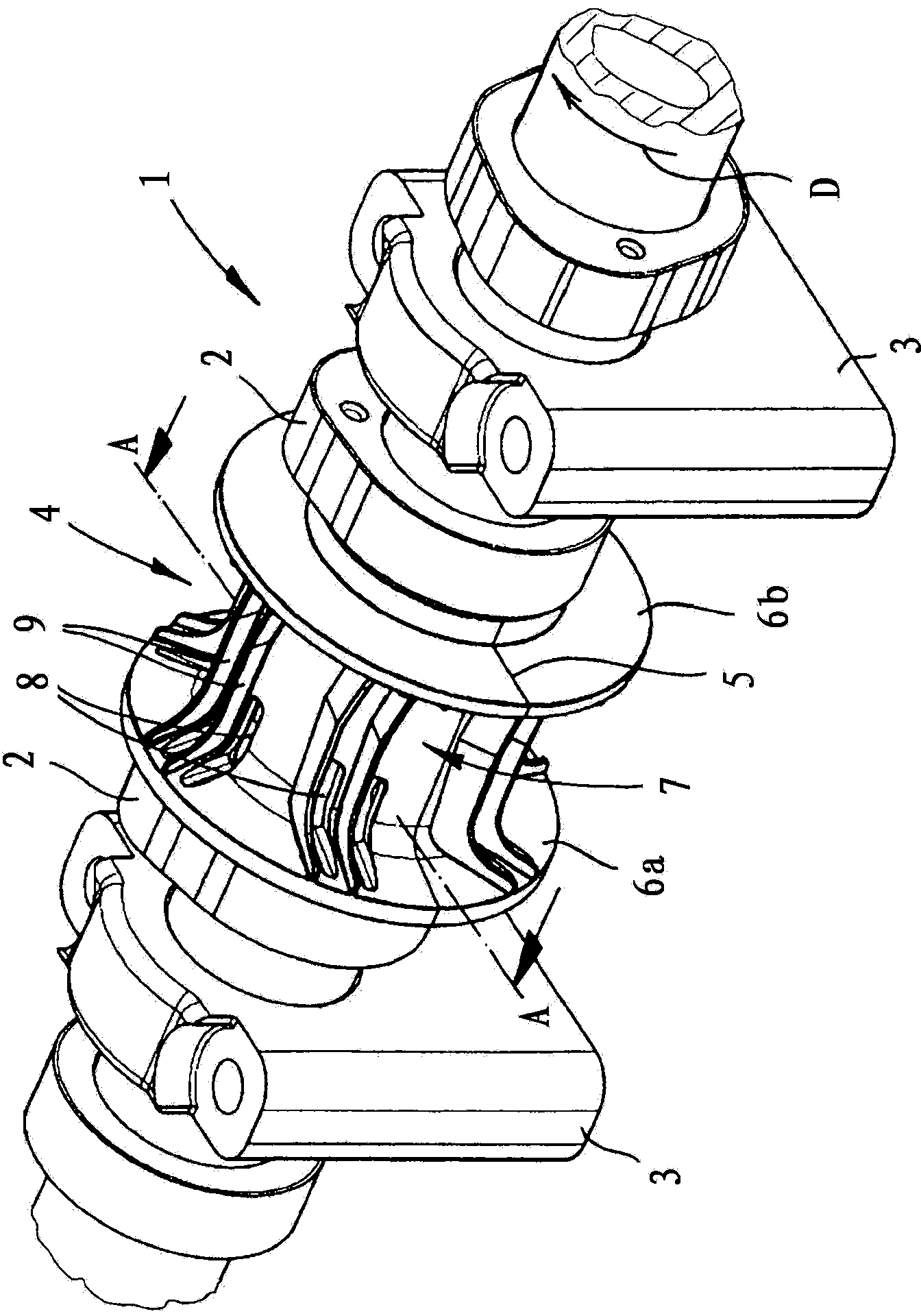

[0028] figure 1 The completed assembled camshaft module is shown, comprising a camshaft 1 which, according to its usual design, has a plurality of cams 2 and which is supported by a bearing block 3 . Between two adjacent cams 2 there is a splash guard 4 , the functional principle of which will be explained in detail below.

[0029] here from figure 1It can be seen that the splash guard 4 is composed of two parts on a boundary surface 5 . It can also be seen that the splash guard 4 has flange-shaped widened ends 6 a , 6 b and a sleeve-shaped, substantially cylindrical middle section 7 lying between them. Visible in the central section are openings 8 in the form of longitudinal slots and projections in the form of ribs 9 which extend in the longitudinal direction of the shaft.

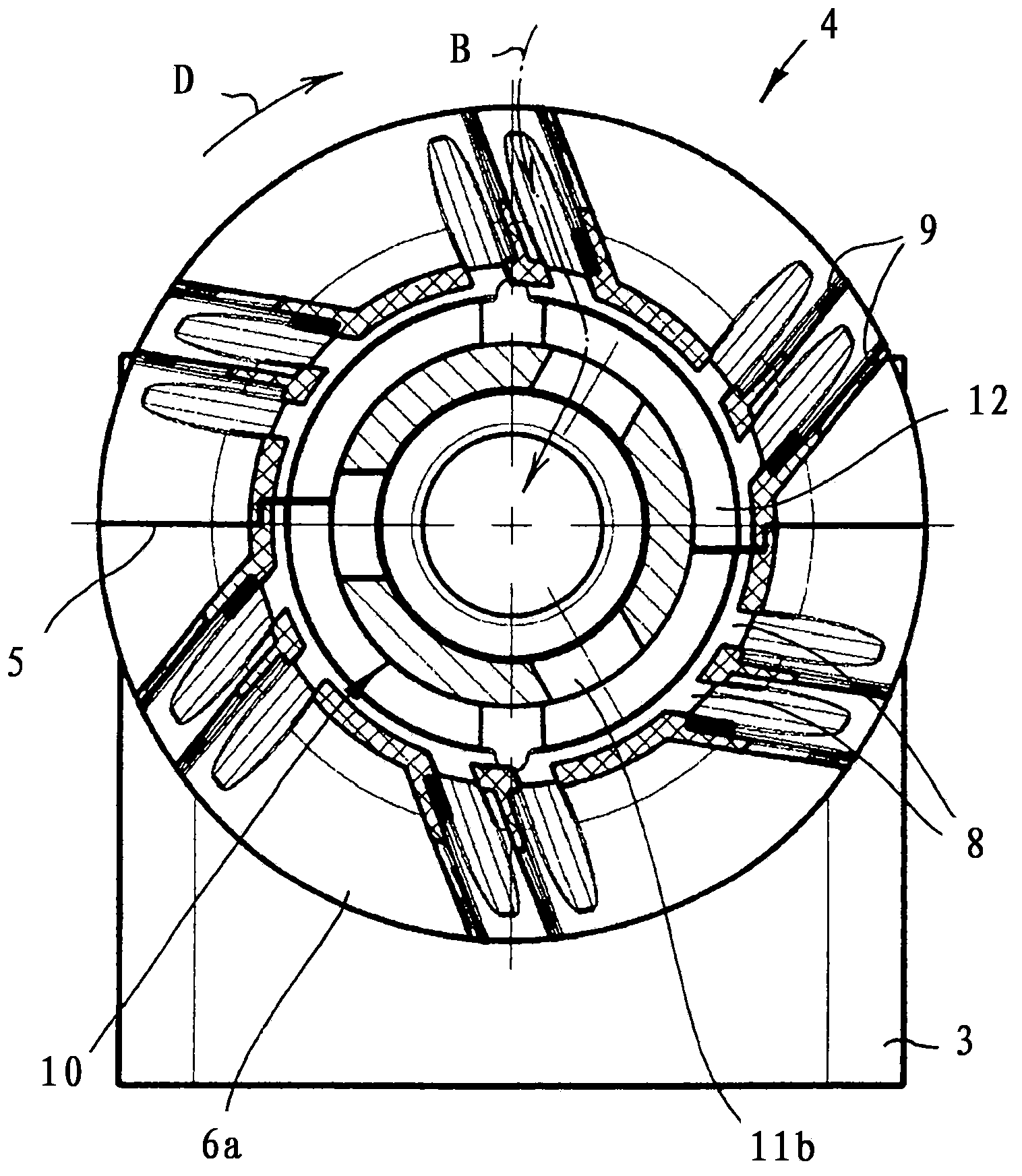

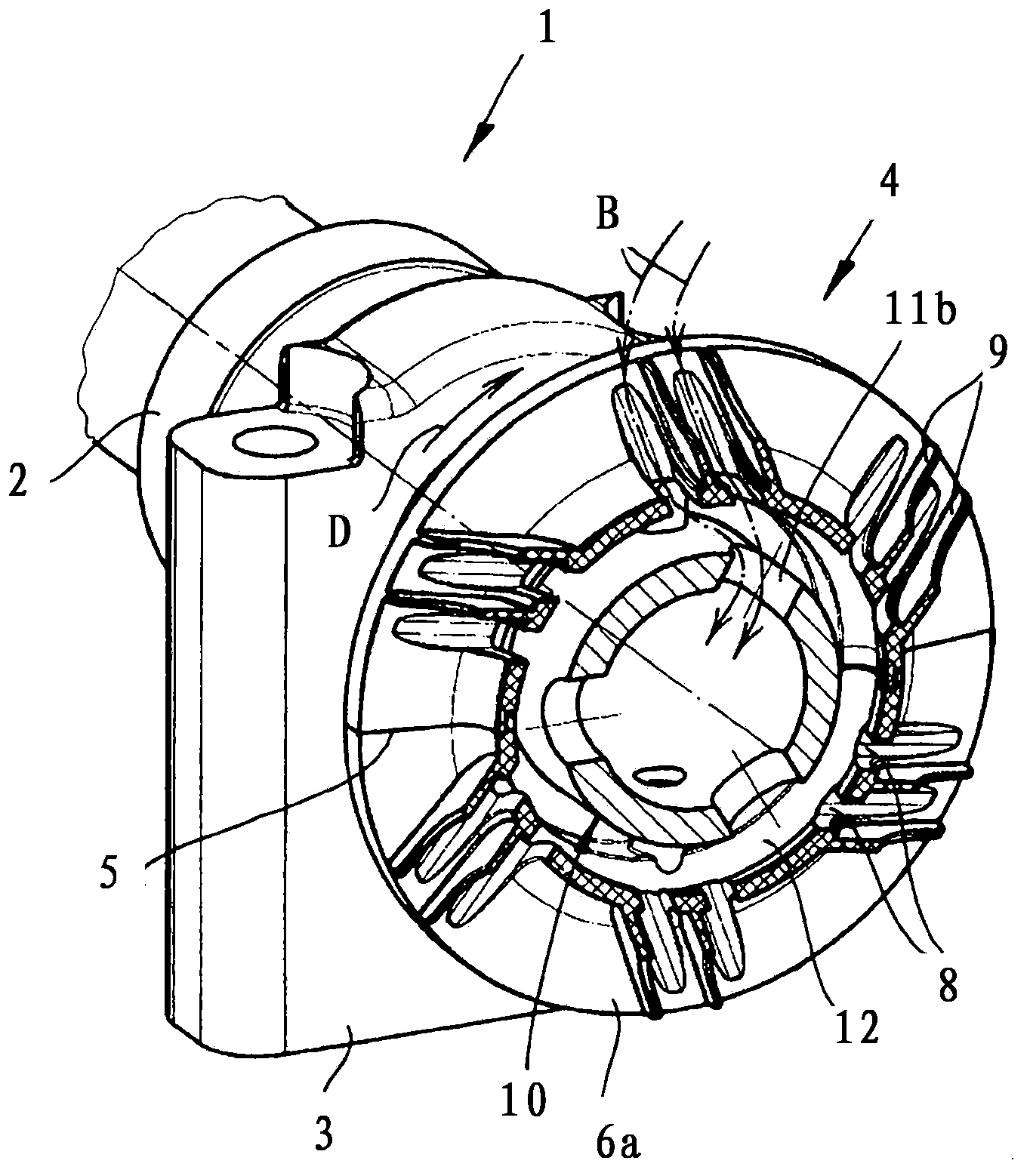

[0030] The purpose of the anti-splash device 4 and the precise design structure of the camshaft 1 from Figures 2 to 4 obtained from the view. here, figure 2 and 3 shows a similar cross-section, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com