Dust falling device for architectural engineering

A technology of dust suppression device and construction engineering, which is applied in the directions of spray device, use of liquid separation agent, dispersion particle separation, etc. Guaranteed efficiency and increased range effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

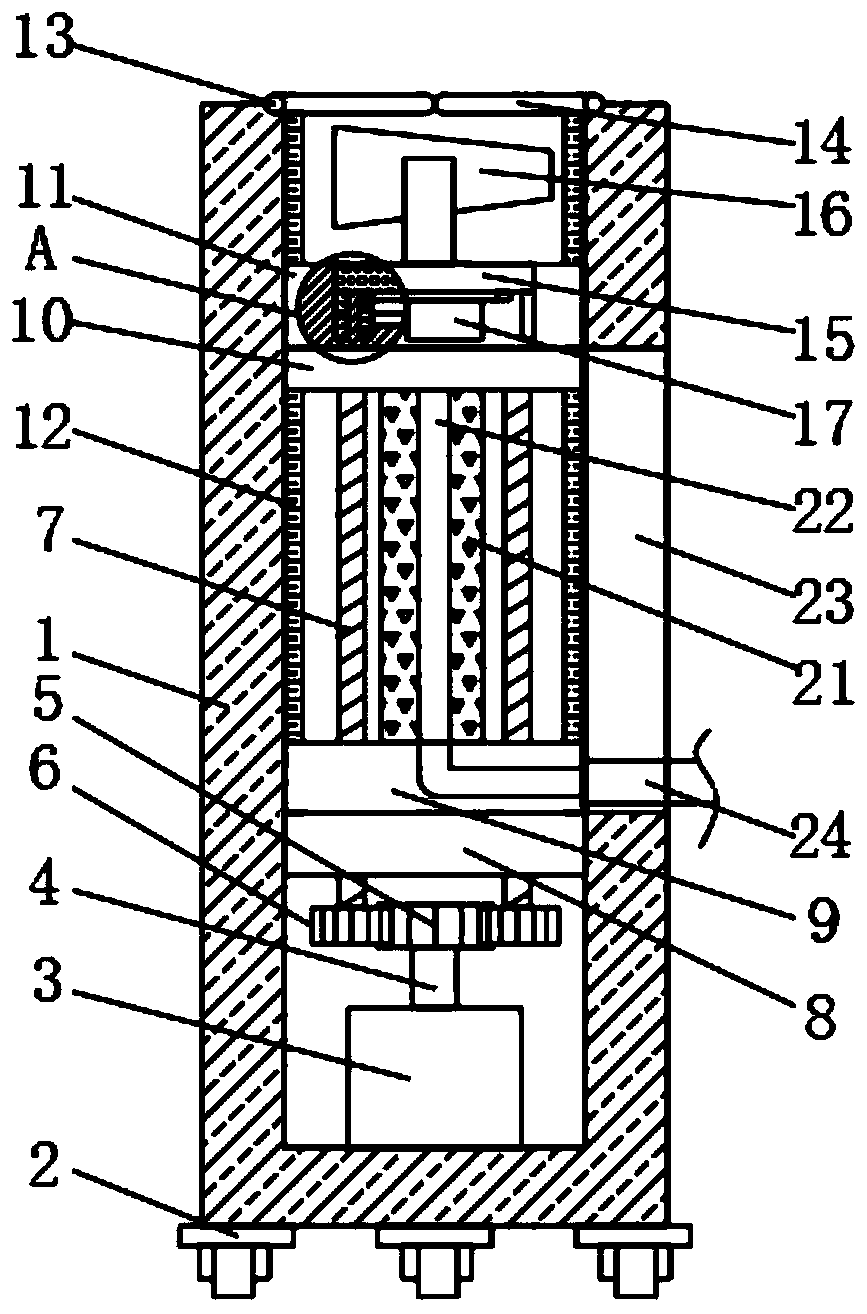

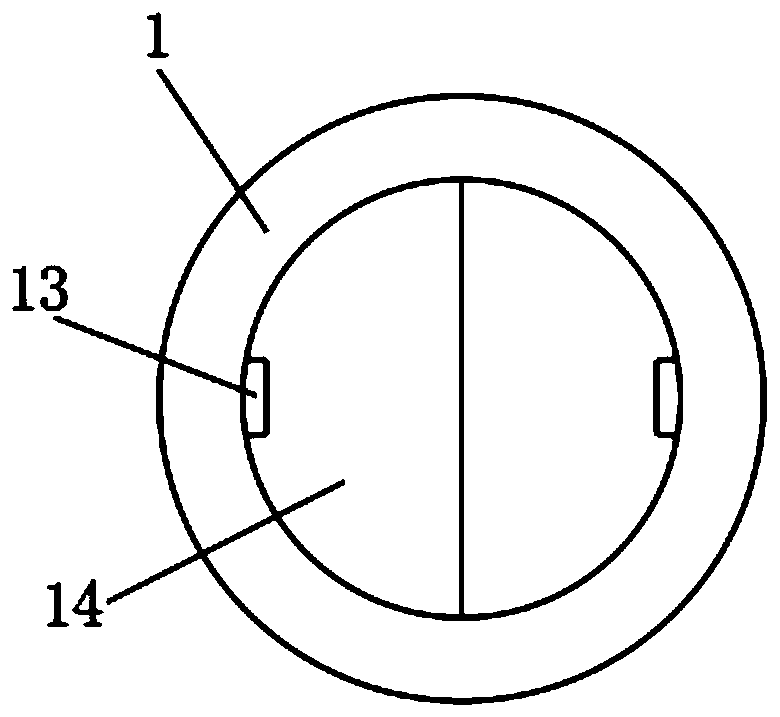

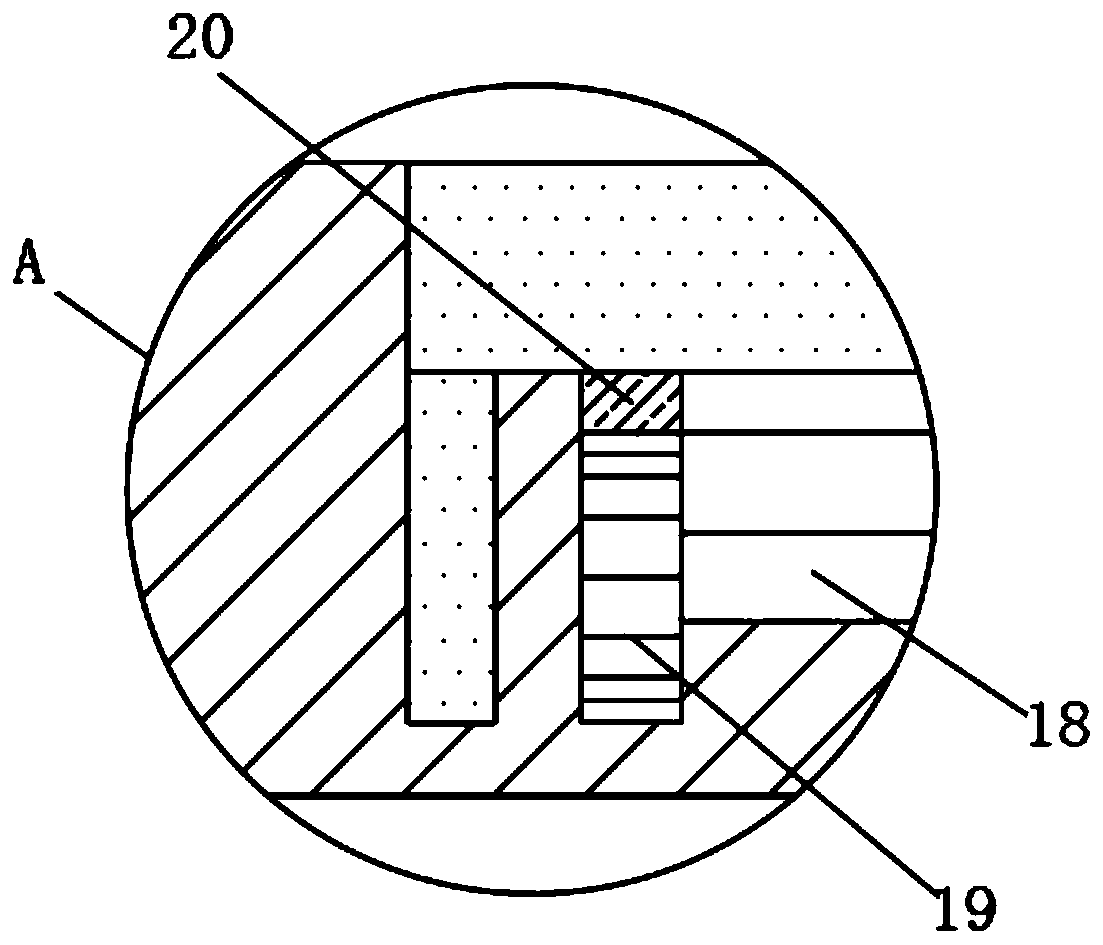

[0022] see Figure 1-6 , the present invention provides a technical solution: a dust suppression device for construction engineering, including a housing 1, the bottom of the inner wall of the housing 1 is fixedly connected with a first motor 3, and the top output shaft of the first motor 3 is welded with a first rotating shaft 4. The top of the first rotating shaft 4 is welded with a driving gear 5, and the outer wall of the driving gear 5 is meshed with three driven gears 6 distributed in a ring with the center point of the driving gear 5 as the center of the circle. The driven gear 6 The top center of the housing 1 is welded with a screw rod 7, the inner side wall of the housing 1 is welded with a chassis 8, the inner side wall of the housing 1 is slidably connected with a lifting plate 9, the inner side wall of the housing 1 is welded with a fixed plate 10, and the inner side of the housing 1 The wall is slidingly connected with a circular base 11, the circular base 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com