Method for finishing gear shaper cutter by diagonal contour evolution of conical worm grinding wheel

The technology of conical worm grinding wheel and worm grinding wheel is applied in the manufacture of gear cutters and gear shaper cutters, which can solve the problems of difficulty in machining tooth top and root chamfering, low efficiency, low machining accuracy, etc., and achieves high machining efficiency. The effect of cost reduction and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

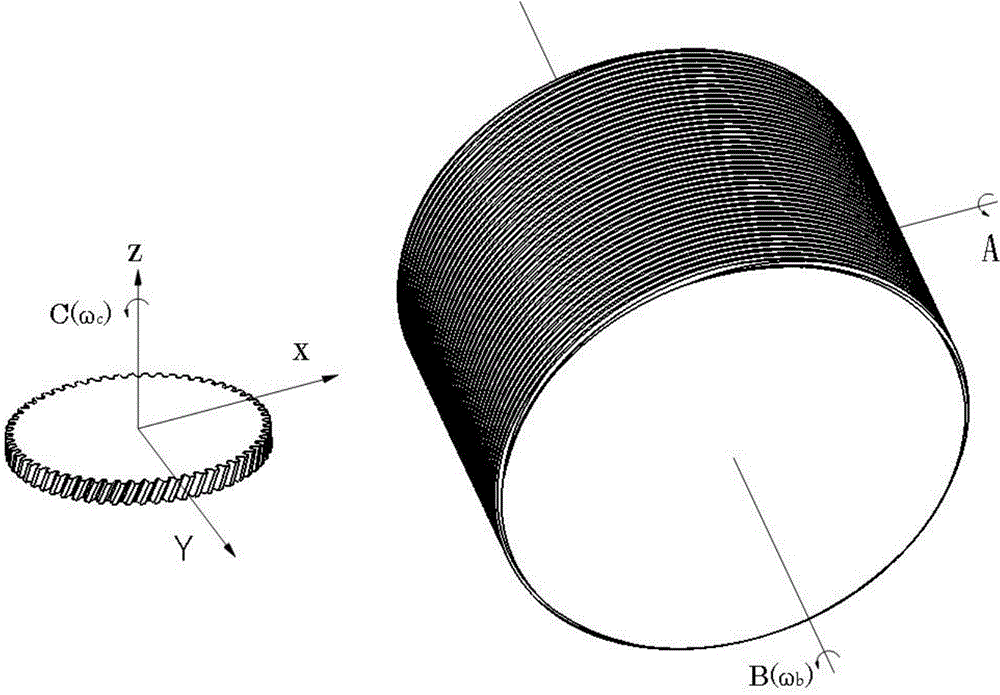

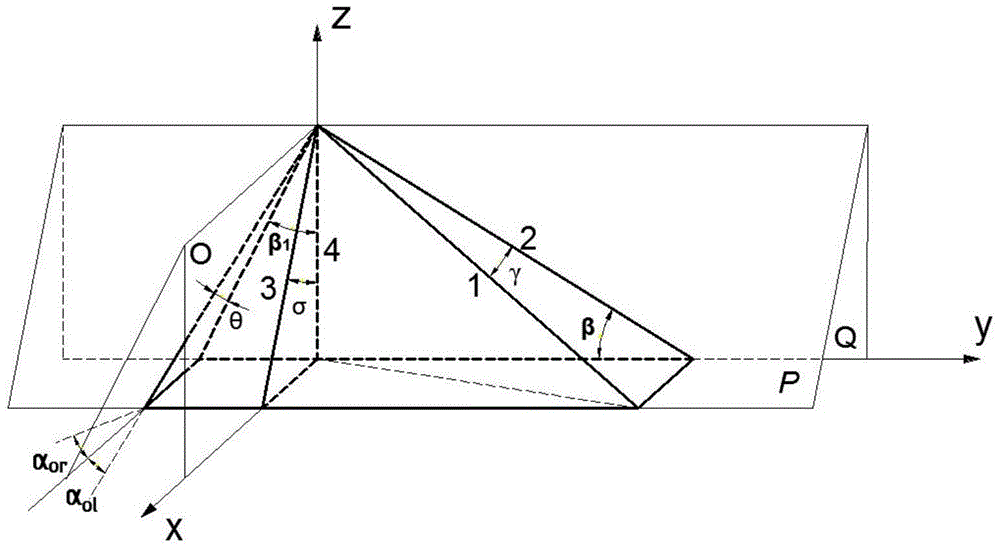

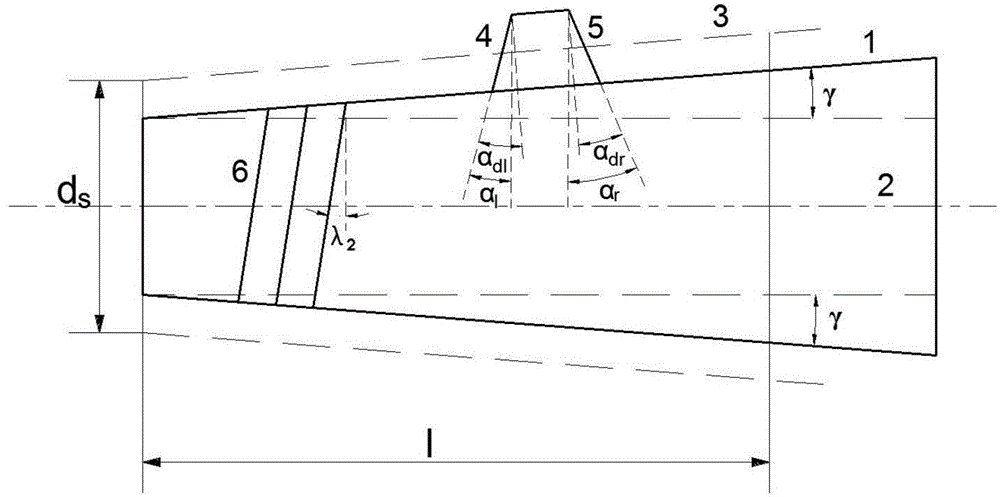

[0038] Use the conical worm grinding wheel to diagonally generate the finishing gear shaping tool method, which is used for grinding the conical worm grinding wheel of the gear shaping tool. The taper of the worm grinding wheel is used to increase the meshing of the grinding wheel and the gear shaping tool Increase the degree of coincidence, increase the length of the meshing line between the grinding wheel and the gear shaper cutter, give full play to the advantages of high precision and high efficiency of the worm grinding wheel generating grinding, improve the processing efficiency of the gear shaper cutter, and reduce the processing cost. The movement process of gear shaping cutter processed by conical worm grinding wheel is similar to cylindrical worm grinding wheel grinding, and the schematic diagram of gear shaping cutter grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com