Artificial diamond compact lathe tool grinding device

A technology of artificial diamond and composite sheet, which is applied in the direction of turning equipment, tools used in lathes, accessories of tool holders, etc., can solve the problems of low diamond grinding removal rate, large consumption of diamond grinding wheel, difficult control of diamond tool size, etc. Achieve the effects of low grinding heat, high product quality and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

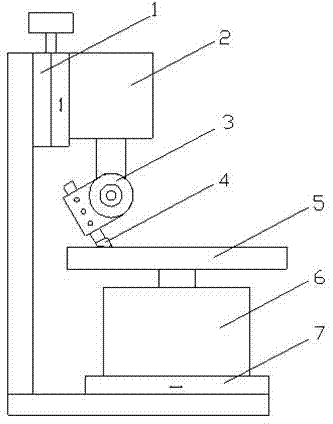

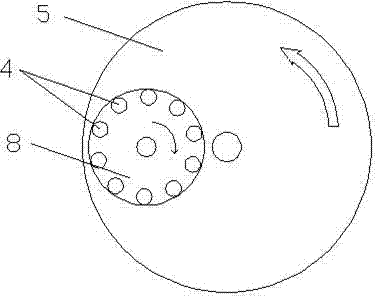

[0021] Such as figure 1 The artificial diamond composite sheet turning tool grinding device shown in , includes a grinding disc spindle head 6 and a grinding wheel grinding disc 5 installed thereon, including a clamping fixture 3, a 360° rotary fixture spindle 2 and a feed carriage 1, so The clamping fixture 3 is connected below the 360° rotary fixture main shaft 2 through a hinge connection, and the 360° rotary fixture main shaft 2 is fixed on the feed carriage 1 that can move up and down, and the workpiece 4 to be ground is The clamping fixture 3 clamps, adjusts the feeding pallet 1, makes the grinding surface of the workpiece 4 to be ground contact with the rotating grinding wheel grinding disc 5, and also includes a swing slide table 7 that can reciprocate in the horizontal direction, and the grinding disc spindle Head 6 is fixed on the described swing slide table....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com