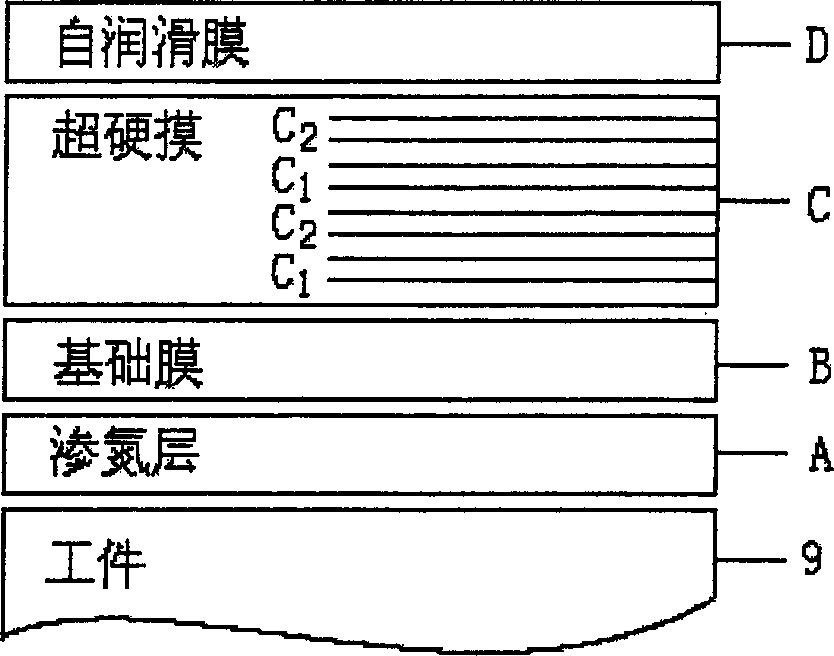

Nano superhard composite film tool with high adhesion and its deposition method

A high-adhesion, composite film technology, applied to the lathe tool, planer/slotting machine tool, milling cutter, etc., can solve the problems of expensive equipment, low equipment configuration, etc., to achieve excellent coating quality, The effect of perfect function and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] 1. Deposition process of superhard composite film

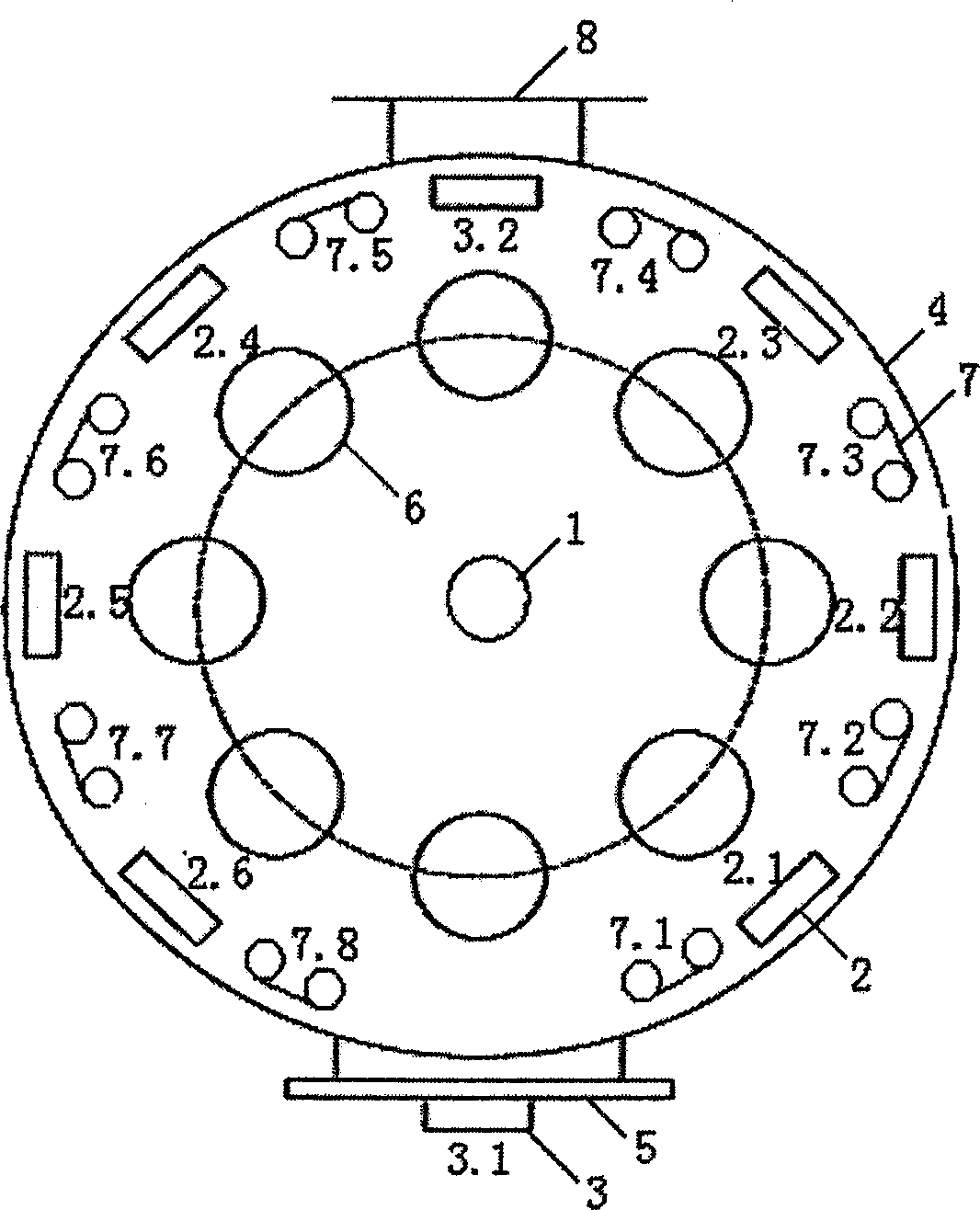

[0075] ①The workpiece is loaded into the furnace

[0076] The workpiece 9 is chemically cleaned, and after being dehydrated and dried, it is clamped on the workpiece frame 6, and the cleanliness of the workpiece 9 and the workpiece frame 6 will be maintained in all operations.

[0077] ② Vacuuming and workpiece baking

[0078] After the workpiece 9 is clamped, close the furnace door 5 of the vacuum chamber 4, start the vacuum unit according to the operating procedures of the vacuum unit, and pump the vacuum chamber 4 to a high vacuum of 3×10 -3 Pa, then turn on the baking heating power supply, control the revolution speed of the workpiece to 4-6 circles per minute, keep the baking temperature at 450±5°C, and keep the vacuum degree at (3±0.5)×10 -3 Pa, maintain for 30 minutes and enter the next step.

[0079] ③Glow ion cleaning

[0080] Introduce argon (Ar) gas, control the air pressure to 2Pa, turn on the pulse bia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com