Method of grinding an indexable insert and grinding wheel for carrying out the grinding method

A technology of indexing blades and rotating grinding wheels, which is applied to tools used in lathes, parts of grinding machine tools, and tools used in planer/slotting machines, etc. It can solve problems such as wired contact, reduce wear of grinding wheels, and improve cooling conditions , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

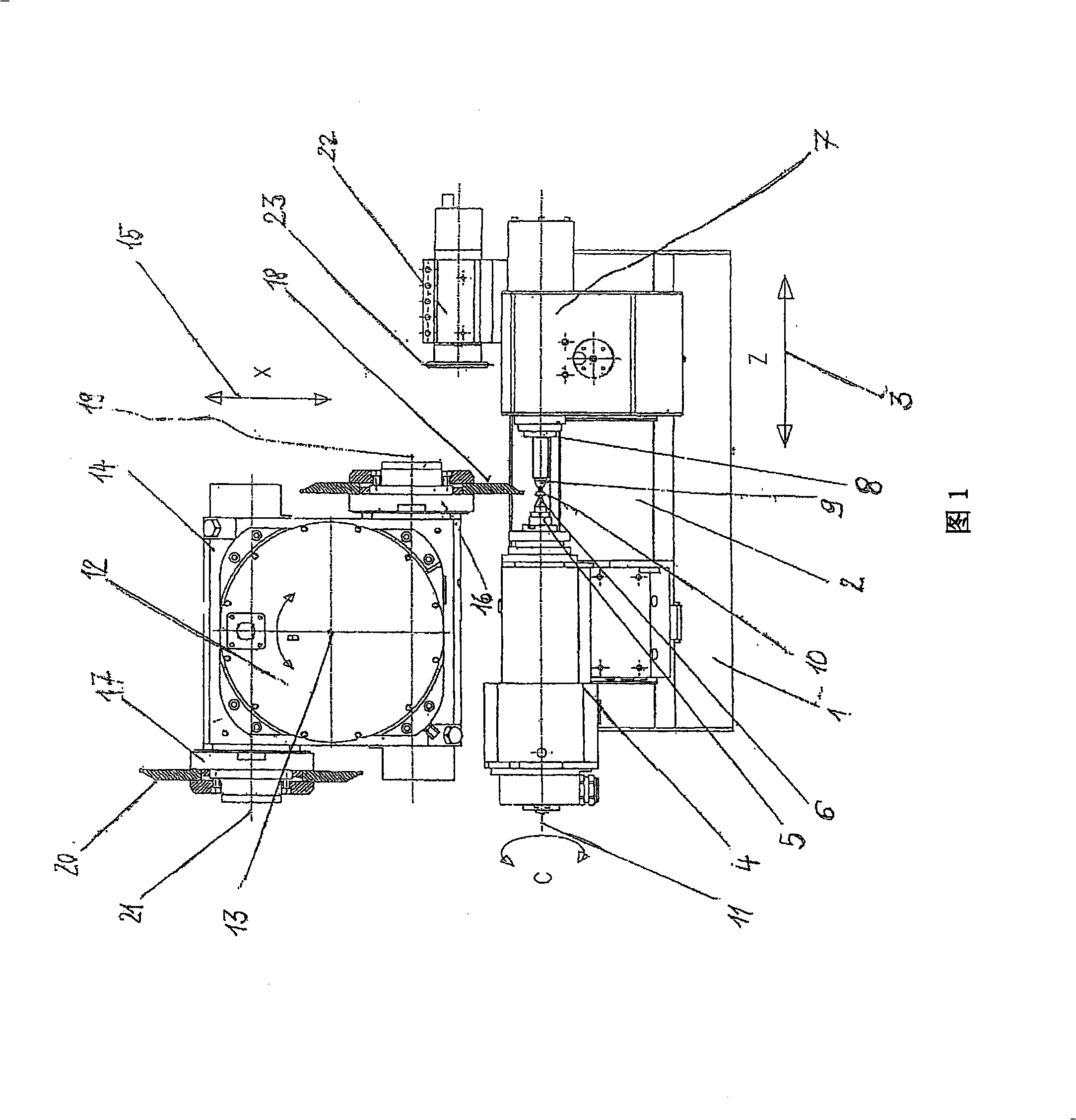

[0039] Figure 1 shows a schematic top view of the grinding machine, which conforms to the structure of a universal circumferential grinding machine and a non-circumferential grinding machine. Most of the parts of the grinder are included in the picture. The table 2 on the bed 1 can move along the first moving axis 3 . The movement axis 3 is generally referred to as the Z-axis in the construction of grinding machines. A head frame 4 with a clamping device 5 and a plug-in clamp 6 is mounted on the workbench 2 . There is a tailstock 7 with a centering clamp 8 and a locking bolt 9 at a certain distance from the headstock 4 . The headstock 4 and the tailstock 7 generally can move towards or in the same direction. The indexable insert 10 can be fixed and centered with a plug-in fixture 6 and clamped with a tailstock 7 and a locking bolt 9 .

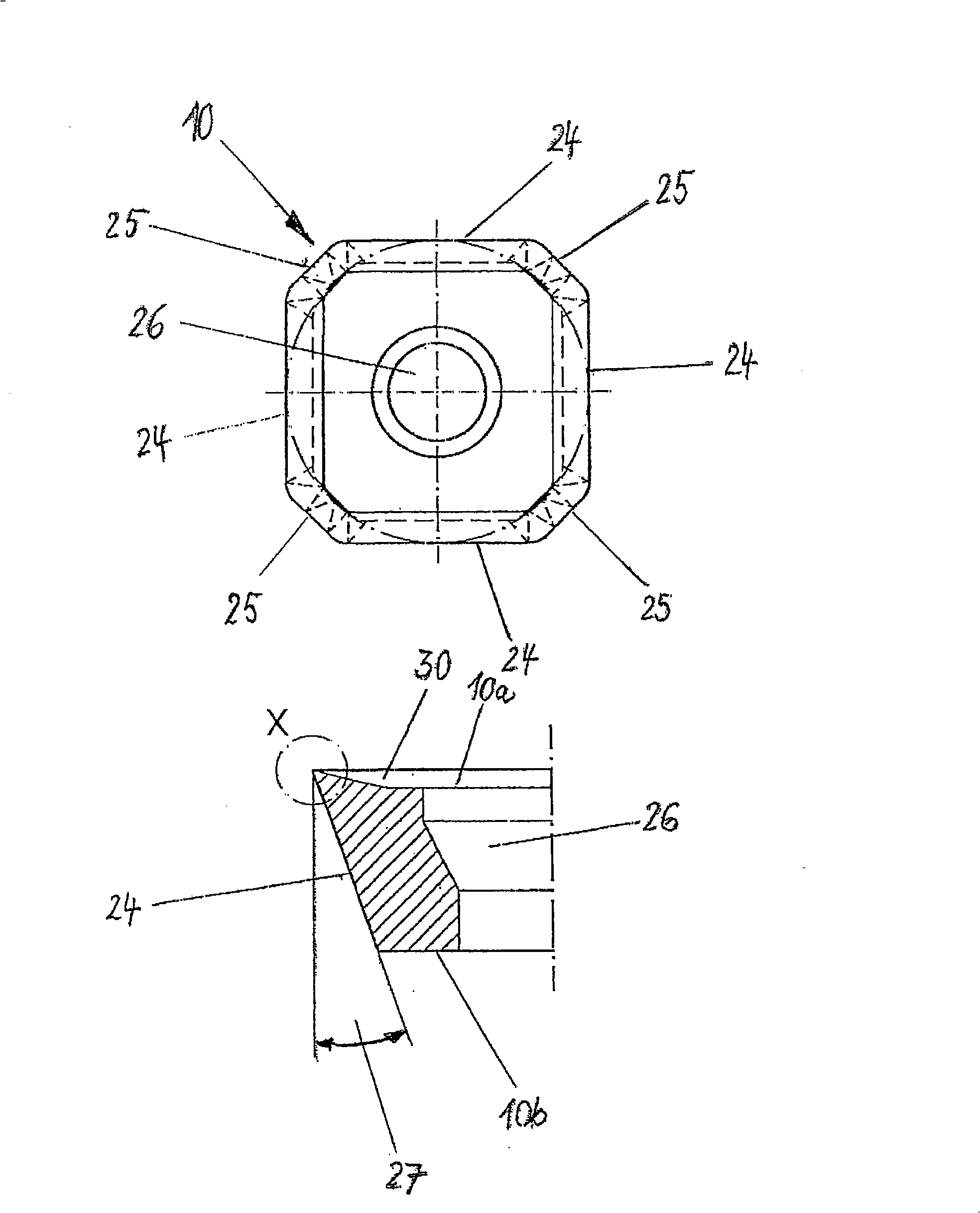

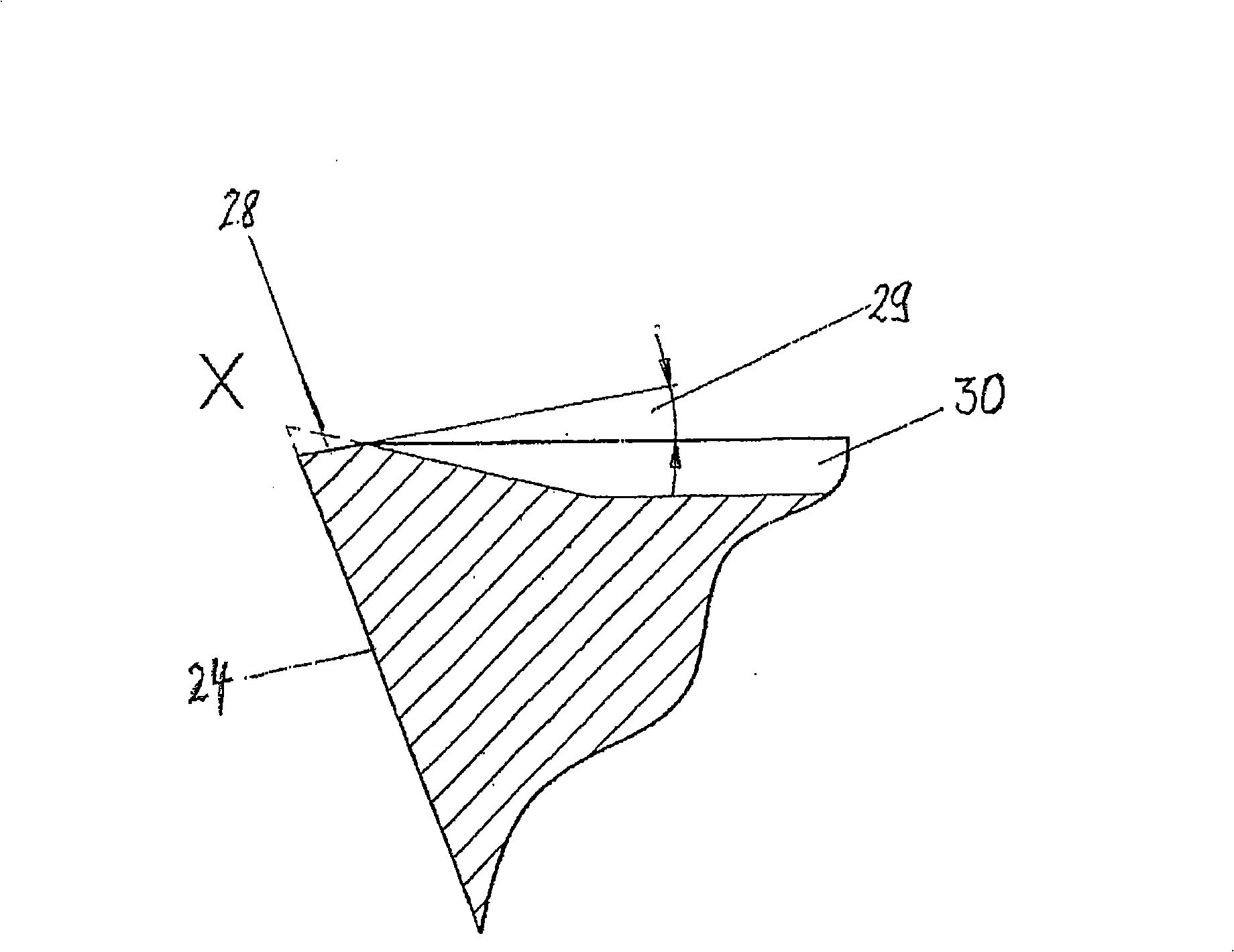

[0040] The indexable insert 10 can be driven to rotate by the head frame 4 . During the grinding process, the indexable insert 10 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com