Grinding machine with a device for conditioning a grinding wheel and a method of conditioning a grinding wheel

A grinding wheel and grinding machine technology, applied in the direction of cutting tools for lathes, cutting tools for planer/slotting machines, abrasive surface adjustment devices, etc., can solve expensive and time-consuming problems, and achieve increased application, precise processing, and optimal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

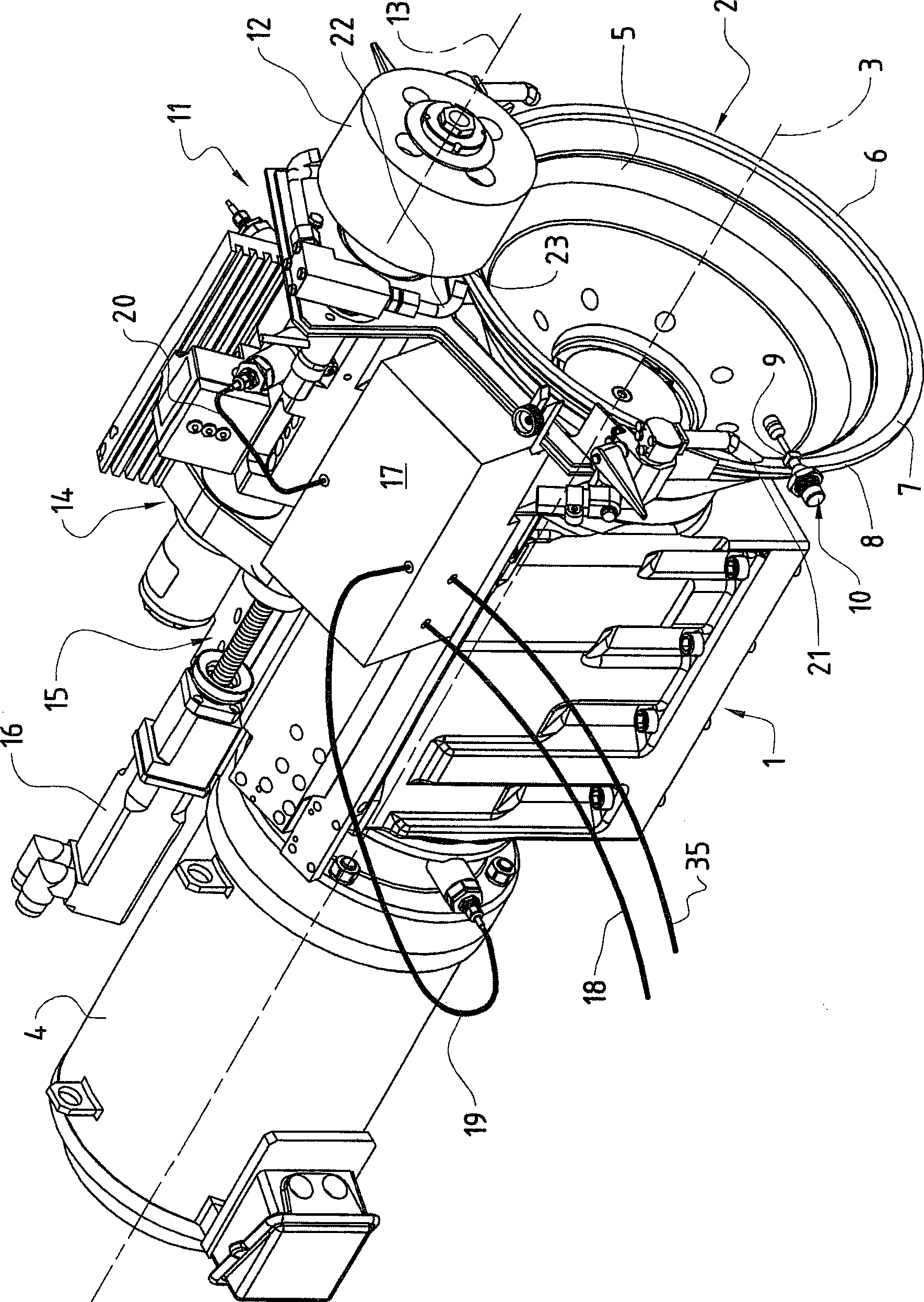

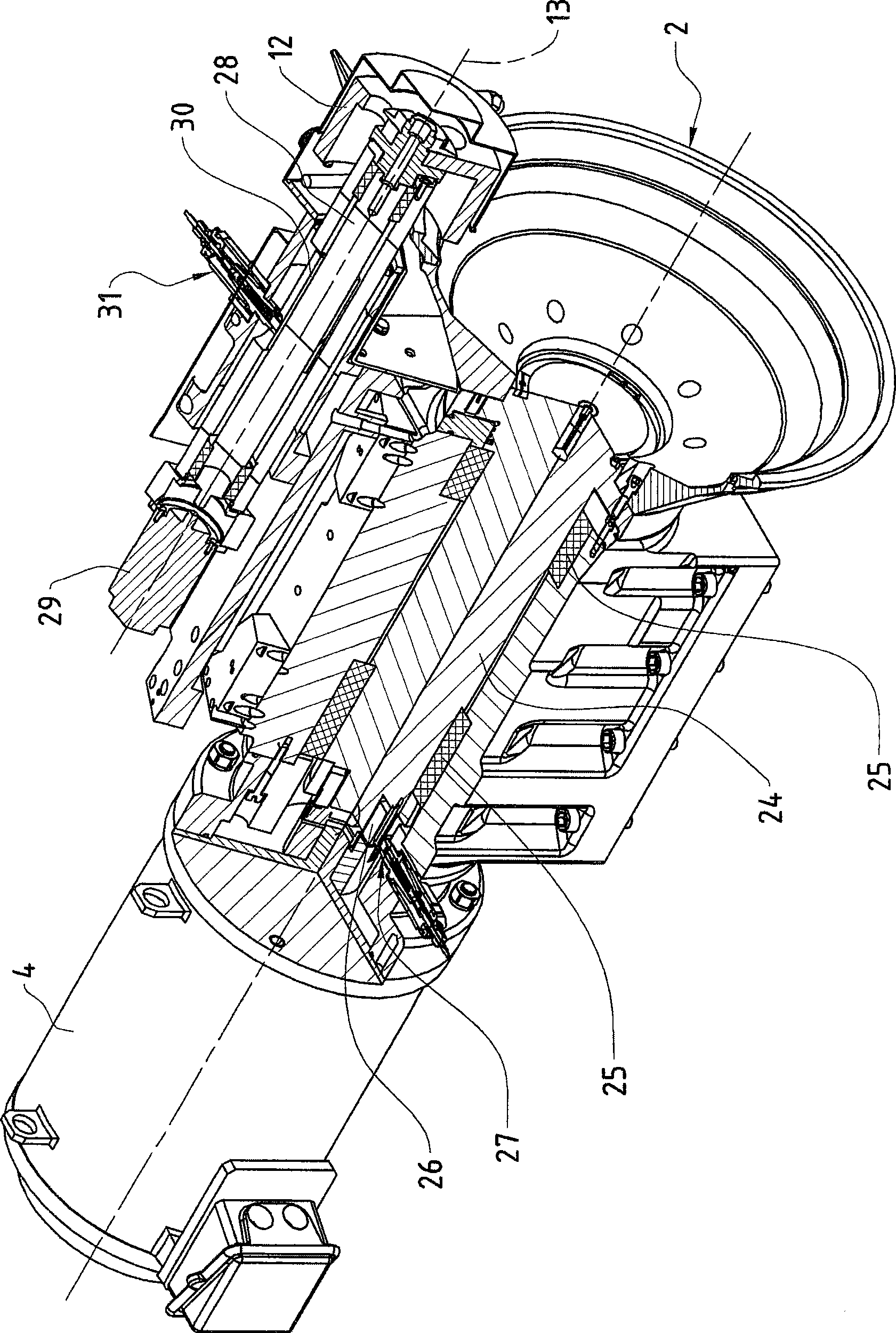

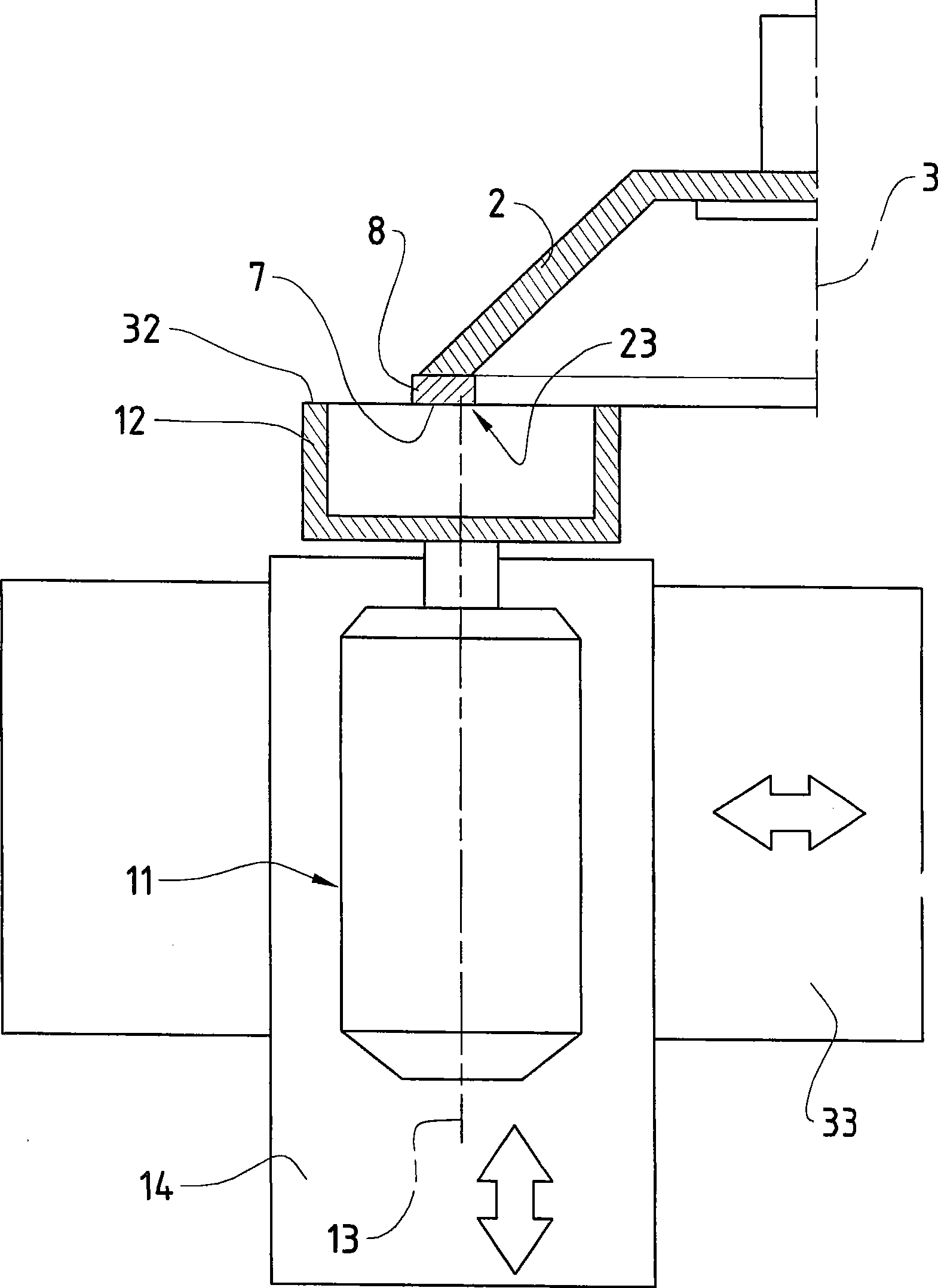

[0035] exist figure 1 The support device 1 is shown, which is arranged in a known manner (not shown) directly on the frame of the grinding machine or on a sliding member between the support device 1 and the frame. The cup-shaped grinding wheel 2 is mounted rotatably about the grinding wheel axis 3 in the bearing device 1 . The grinding wheel 2 is driven in rotation by an electric motor 4 which is arranged on the support device 1 .

[0036] Cup-shaped grinding wheel 2 comprises a grinding wheel cup 5 on which a grinding ring 6 is arranged, which has an annular grinding surface 7 and a grinding surface 8 in the form of a side region. A workpiece 9 , for example an indexable insert, can be ground by means of the grinding wheel 2 , said workpiece 9 being held in a known manner by a component 10 provided in the grinding machine for holding the workpiece 9 to be ground.

[0037] The device 11 for reconditioning the grinding surfaces 7 , 8 of the cup-shaped grinding wheel 2 has a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com