Method for preparing high-precision arc-blade diamond lathe tool

A diamond and arc edge technology, used in turning equipment, metal processing equipment, tools for lathes, etc., can solve the problems of large financial resources and time, low production efficiency, high price, and improve efficiency and edge precision. , high-precision machining, eliminating unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

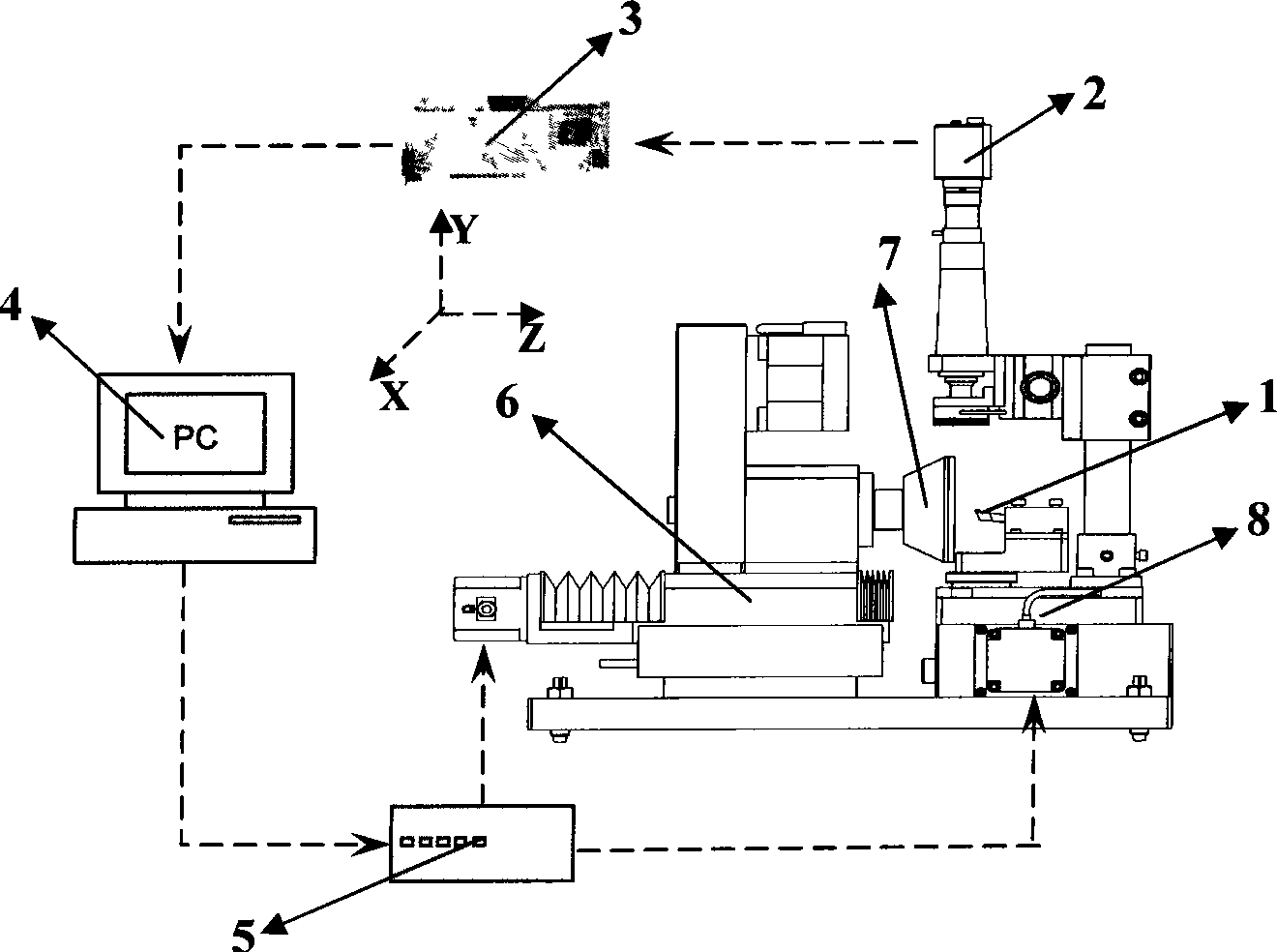

[0025] Carry out the diamond cutter of preliminarily formed (rough machining) by the inventive method and prepare high-precision circular arc edge diamond turning tool (R0.2mm) based on online image processing, and concrete processing process is as follows:

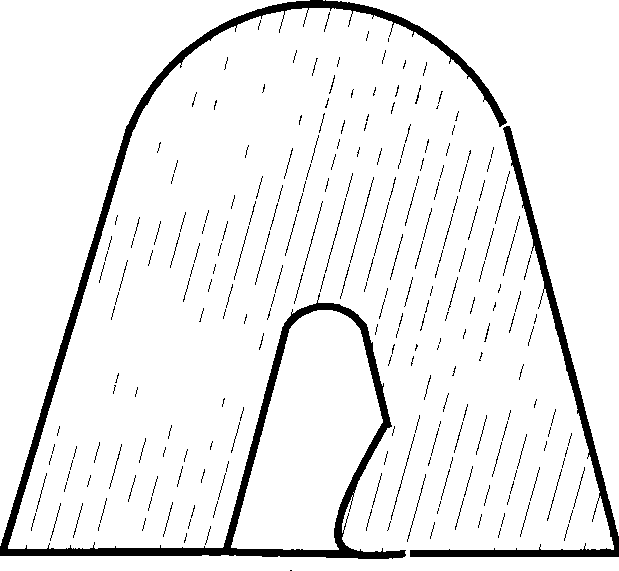

[0026] (1) Select a roughly machined diamond turning tool with a radius of about 0.205mm, and the shape of the arc edge at the tip has been initially formed, such as figure 2 As shown, install it on the swing table 8 (see figure 1 );

[0027] (2) Complete the initialization of the image acquisition card, control card and other parts, and set the target contour accuracy of the cutting edge of the tool to 0.1 μm;

[0028] (3) Start the image processing system, perform image measurement on the front end of the tool, use the aforementioned image processing method to obtain the contour of the cutting edge, and use the polygonal approximation method to segment the front end arc to obtain the initial (approximate) arc of the c...

Embodiment 2

[0032] Prepare high-precision circular arc edge diamond turning tool (R0.2mm) based on online image processing by the inventive method to diamond turning tool blank (unprocessed, polygon), and concrete processing process is as follows:

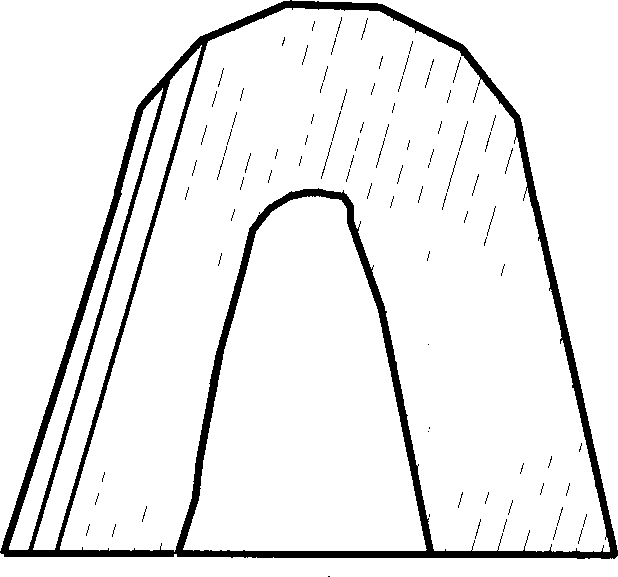

[0033] (1) Select a diamond turning tool blank 1 with an unprocessed tip, and its tip shape is as follows: image 3 shown. Mounted on the swivel table 8 (see figure 1 );

[0034] (2) Complete the initialization of various parts such as the image acquisition card and the control card, and set the target contour accuracy of the cutting edge of the tool to 0.1 μm;

[0035](3) Start the image processing system to perform image measurement on the front end of the tool. The contour of the cutting edge is obtained by using the aforementioned image processing method, and after the cutting edge contour polygon of the collected tool front end image is appropriately reduced, the polygon can be segmented as a circular arc, and the initial approximate a...

Embodiment 3

[0040] Prepare the high-precision circular arc edge diamond turning tool (R0.5mm) based on online image processing to the damaged diamond turning tool (indeterminate shape) used by the inventive method, and the specific processing process is as follows:

[0041] (1) Select the diamond turning tool 1 that needs to be trimmed when the cutting edge is damaged, and its tip shape is as follows: Figure 4 shown. Mounted on the swivel table 8 (see figure 1 );

[0042] (2) Complete the initialization of various parts such as the image acquisition card and the control card, and set the target contour accuracy of the cutting edge of the tool to 0.1 μm;

[0043] (3) Start the image processing system to perform image measurement on the front end of the tool. Adopt the aforementioned image processing method to obtain the outline of the cutting edge, which is similar to embodiment 2, and after appropriately reducing the collected tool front end image according to the cutting edge outline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com