Forged steel gate valve flashboard guide groove processing equipment and forged steel gate valve flashboard guide groove processing method

A technology for processing equipment and gate valves, which is applied in forged steel gate valve processing equipment and processing fields, can solve the problems of low efficiency, difficult to guarantee processing accuracy, poor processing quality of forged steel gate valve gate guide grooves, etc., to reduce production costs and improve production efficiency High, good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

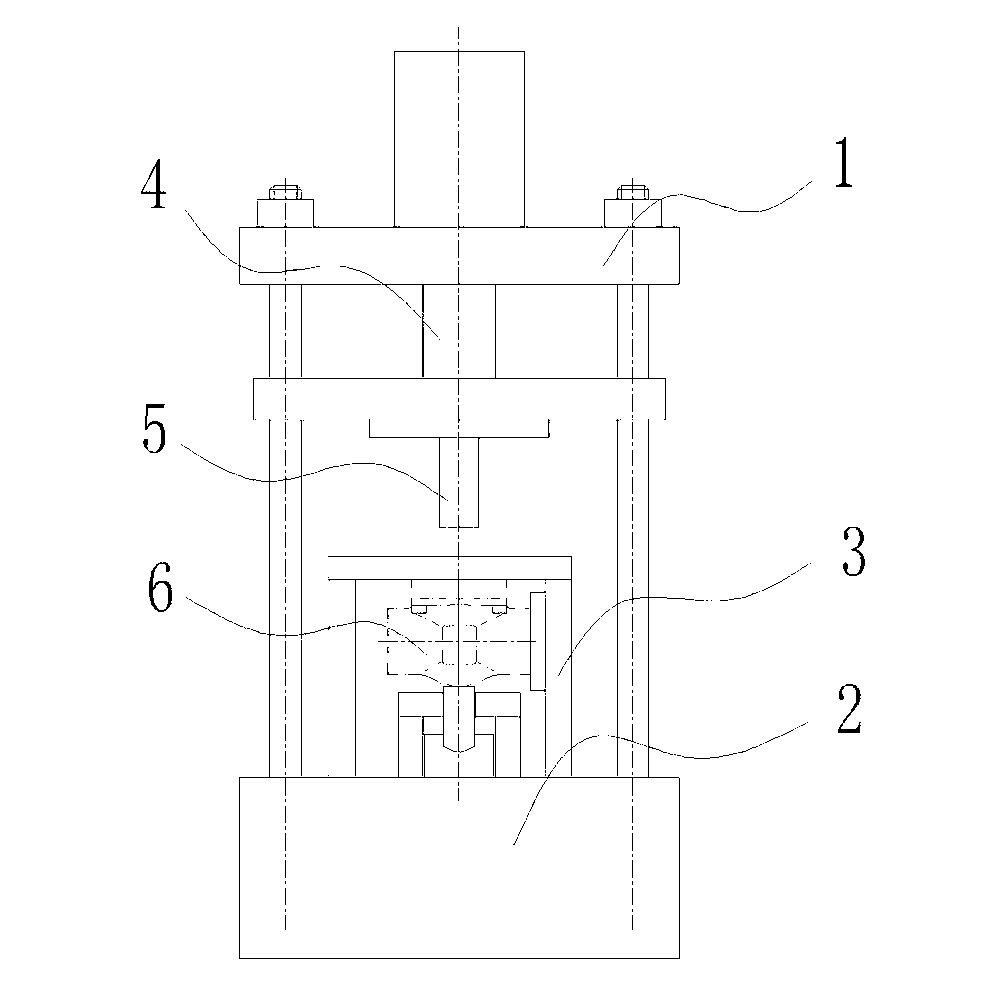

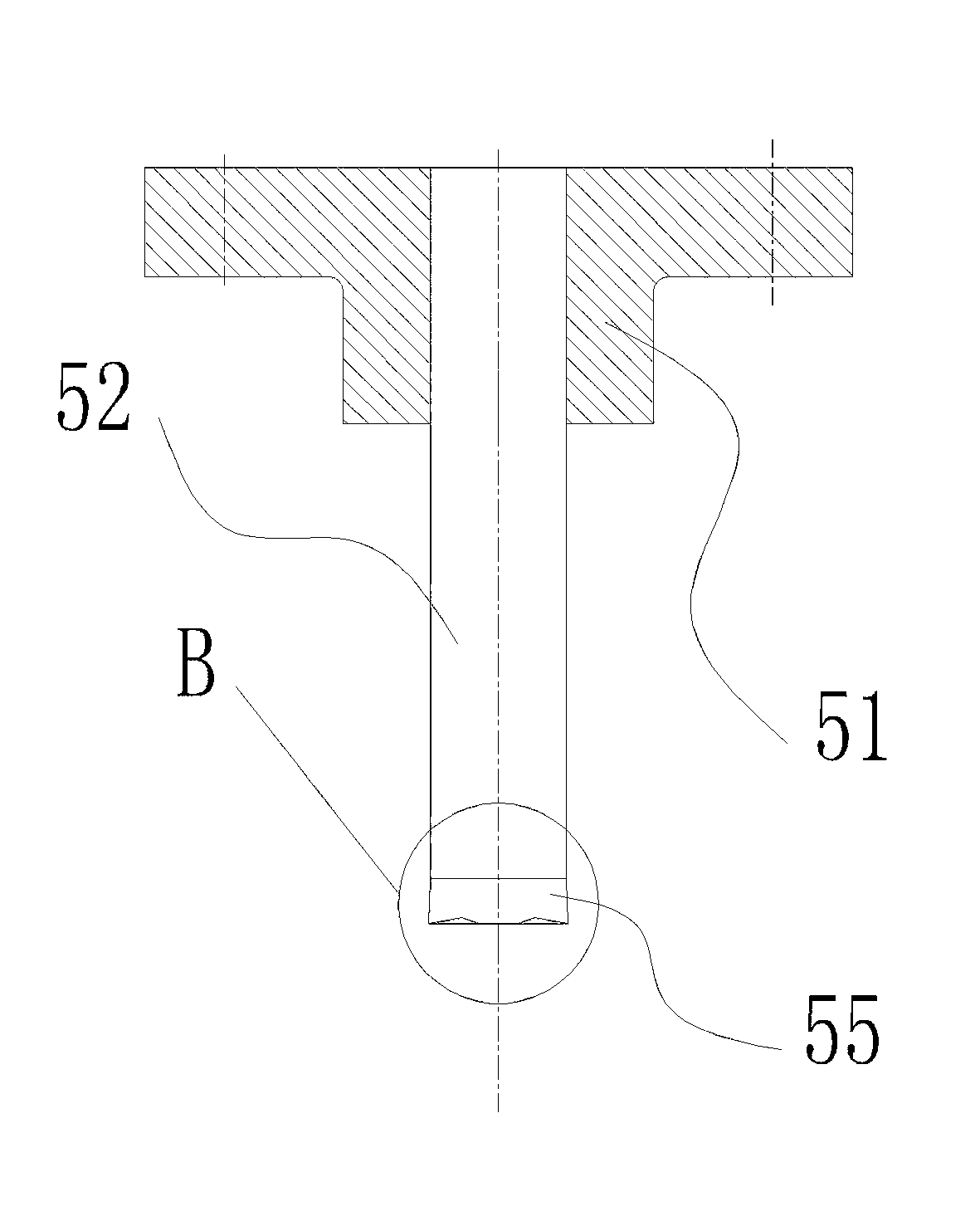

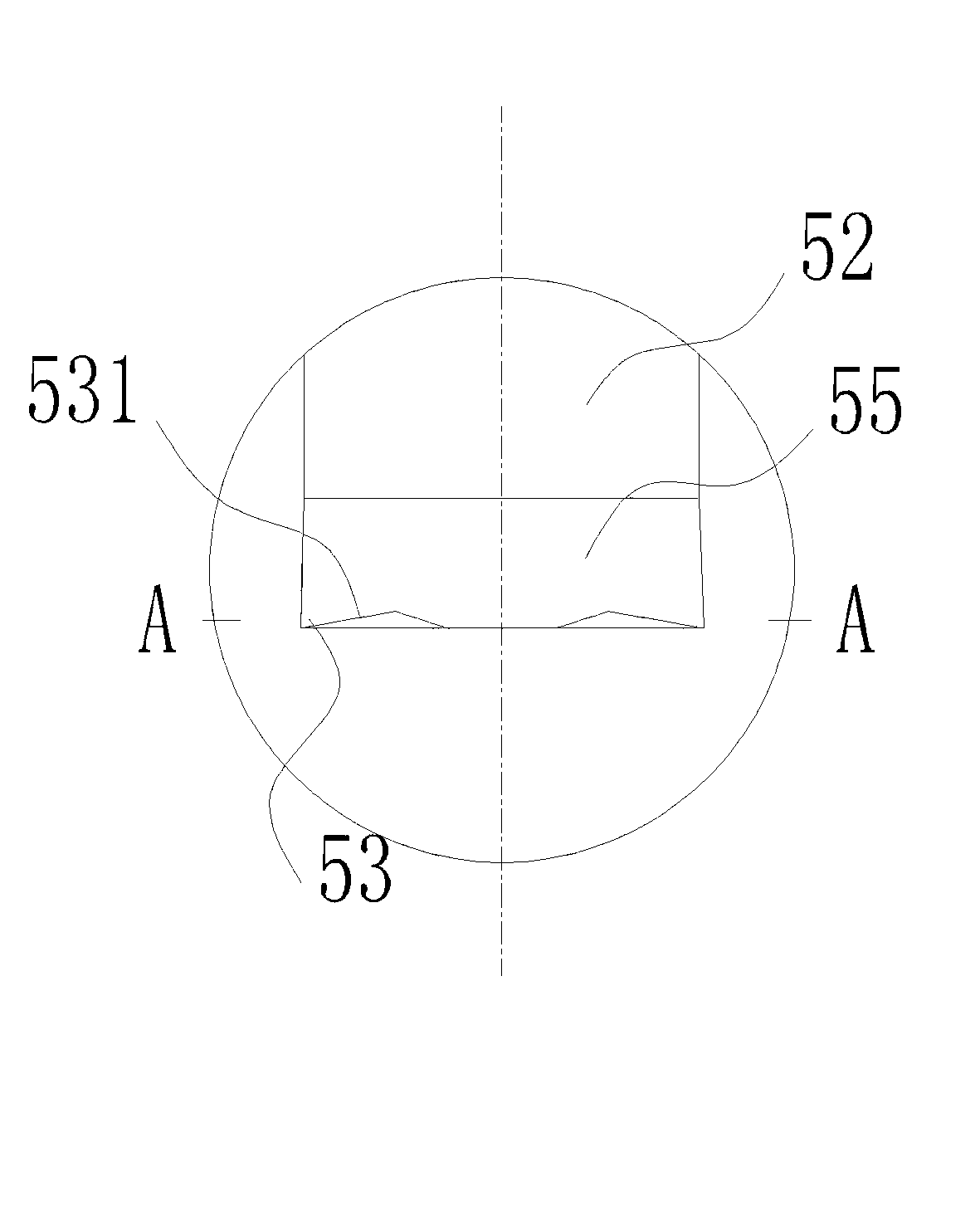

[0038] like figure 1 As shown, a forged steel gate valve gate guide groove processing equipment of the present invention includes a four-column hydraulic press 1, a main oil cylinder 4 that can be vertically lifted is fixed above the hydraulic press 1, and a movable beam corresponding to the lower end of the main oil cylinder 4 is A forming knife 5 is coaxially fixed, and a workbench 2 is arranged horizontally below the forming knife 5, and a fixture 3 for clamping the gate valve body is fixed on the workbench 2, and the fixture 3 is coaxial with the forming knife 5 Yes, and the clamp 3 is equipped with a travel switch for controlling the stroke of the forming knife 5, such as figure 2 , Figure 5 and Image 6 As shown, the forming knife 5 wherein includes a handle 51 and a columnar structure cutter body 52 fixed on the handle 51, the cutter body 52 is made of white steel, its cross section is rectangular, and the handle 51 is in the shape of a flange , its flange surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com