Machining process of spline inside blind hole in shaft end

A processing method and internal spline technology are applied in the field of metal precision cutting to achieve the effects of improving processing efficiency, realizing interchangeability and improving rigidity

Inactive Publication Date: 2004-04-07

JIANGSU GANGYANG STEERING SYST

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to overcome the disadvantages of the existing method of slotting and machining the internal splines of blind holes at shaft ends, and provide a method for processing internal splines in blind holes at shaft ends with simple operation, high production efficiency and improved machining accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

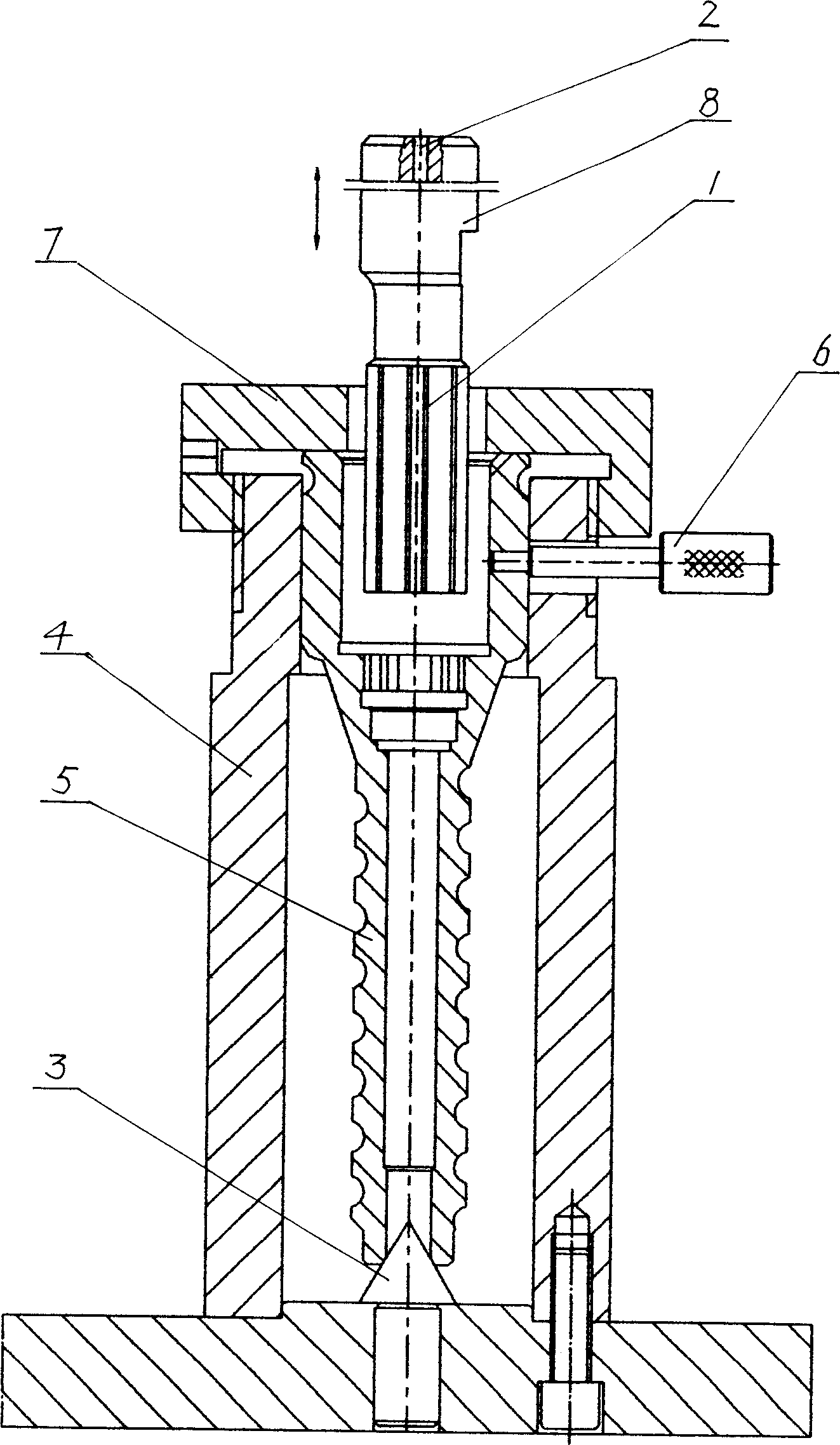

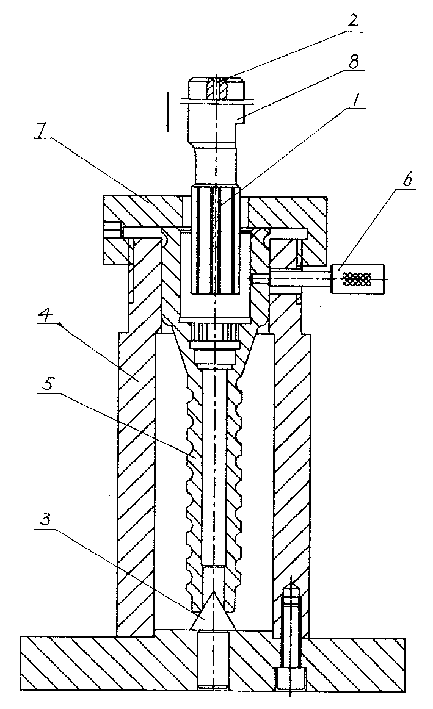

The present invention is machining process of spline inside blind hole in shaft end in high maching speed and high precision. The machining process includes setting the machining shaft vertically inside positioned fixture for positioning and clamping with the end to be machined being in the top; and driving the toothed forming pushing broach for cutting via vertical reciprocation after the working head of the press is positioned. The pushing broached amount is designated to the forming pushing broaches, and, for example, the pushing broached amount for rectangular tooth is designated to 8-11 forming pushing broaches. During the cutting, the toothed forming pushing broaches are used successively in the order from small outer diameter one to large outer diameter one.

Description

technical field [0001] The invention relates to a method for processing a spline in a blind hole at a shaft end, and belongs to the technical field of metal precision cutting. Background technique [0002] The shaft is an indispensable part of the machine, and sometimes the shaft needs to be designed with splines due to its structure. The conventional production method of external splines is that milling is the main method for single piece or small batch, and broaching is the main method for mass production. The processing of internal splines is not as easy as that of external splines, especially the processing accuracy of internal splines in blind holes at shaft ends is greater. The conventional method of cutting internal splines in blind holes at shaft ends is single-tooth slotting processing, and the shaft to be processed is positioned It is clamped on the slotting machine table, divided into equal parts according to the number of teeth with a circular indexer, and singl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23D13/00B23P17/02

Inventor 宋海兵张如清王春宏

Owner JIANGSU GANGYANG STEERING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com