Method and apparatus for non-rotary machining

a non-rotary, method and equipment technology, applied in mechanical equipment, turbines, manufacturing tools, etc., can solve the problems of inability to produce surface types using prior art milling techniques, inability to produce other methods or equipment for machining, and inability to achieve axial symmetry constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

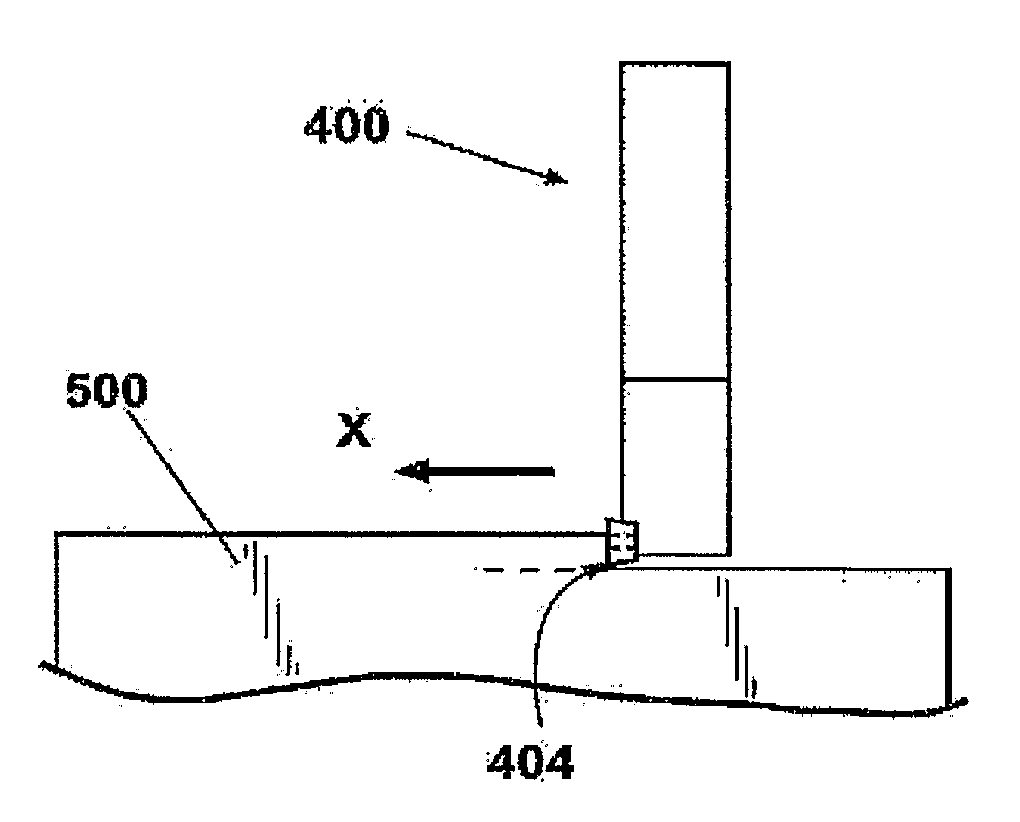

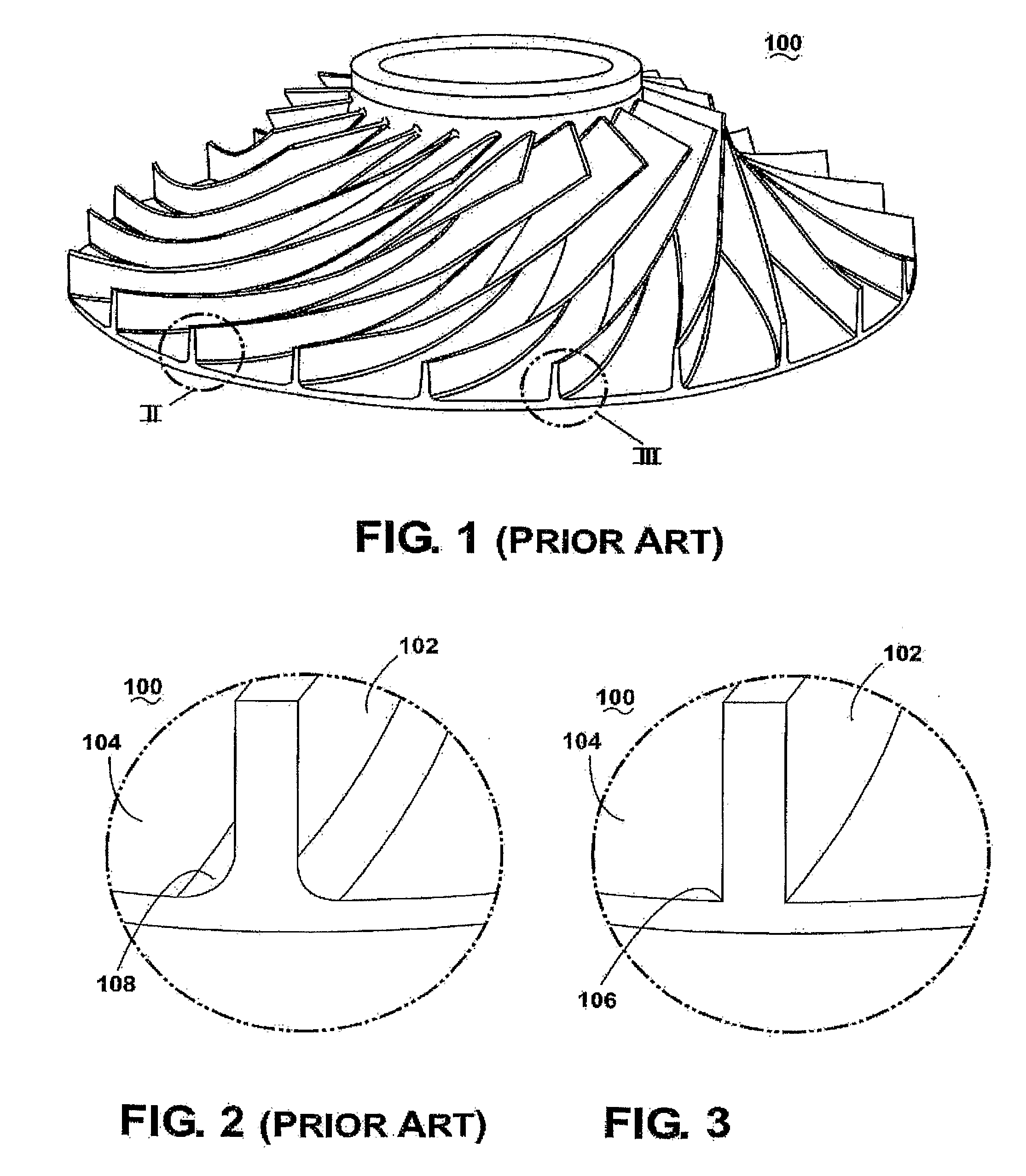

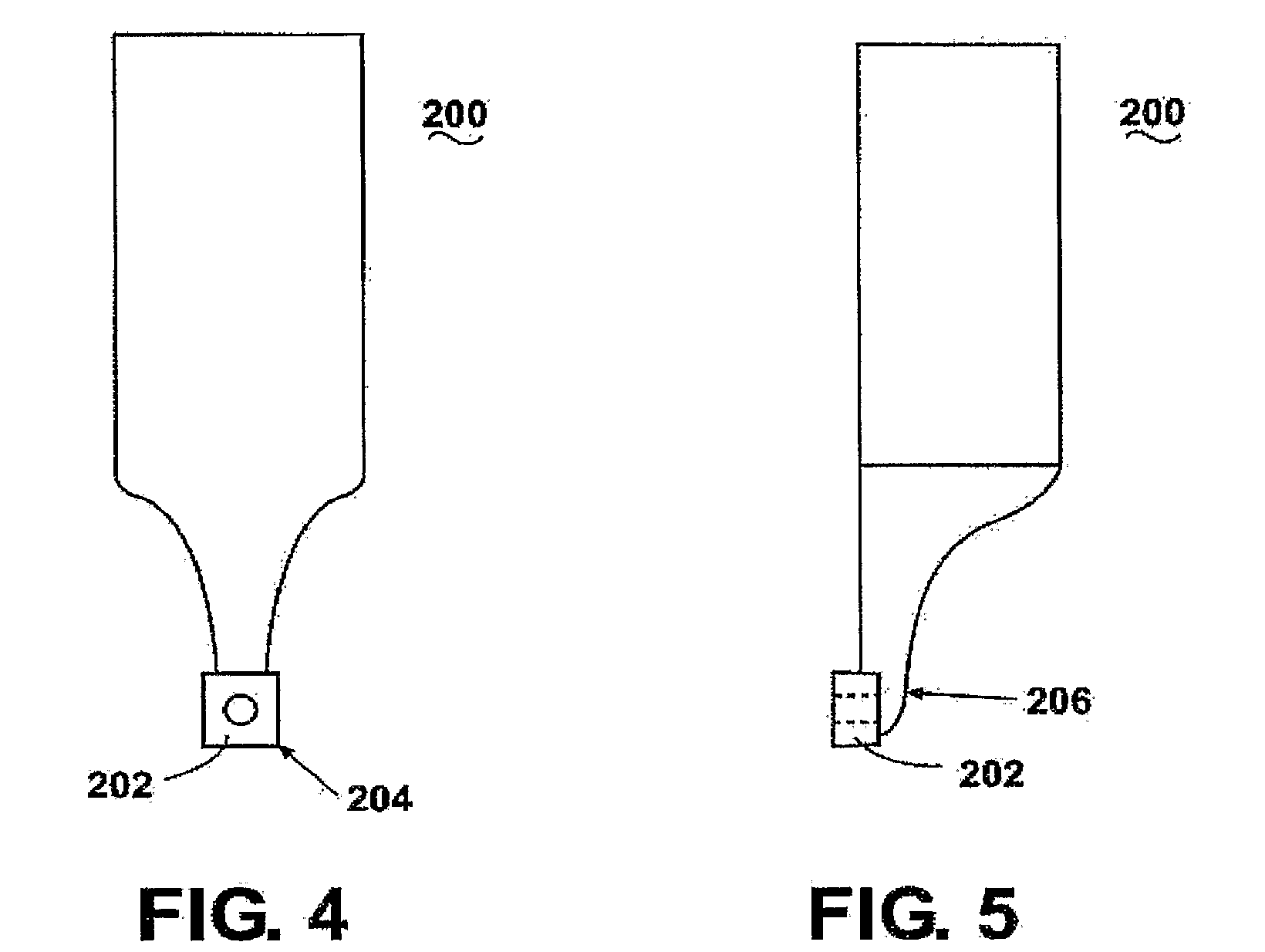

[0027]Comparison with the Prior Art. The present invention is distinguished from current machining methods and apparatuses for profiling operations by: [1] A non-rotating cutting tool that is unconstrained by axial symmetry and [2] driven along a one-, two-, or three-dimensional cutting path [3] within a three-dimensional work envelope [4] to remove material from a non-rotating workpiece. No other method or apparatus for machining possesses all of these characteristics. As a consequence of these characteristics the present invention can machine: [1] Parts with an unrestricted range of shapes from simple to complex, symmetrical and asymmetrical, [2] including those with thin cross-sections, [3] with fine surface finishes [4] at high rates of material removal. No other method or apparatus for machining can produce these results on a single machine tool in a single profiling operation. The comparison of these characteristics and capabilities between the present invention and prior art ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface footage | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com