Large-size micro-prism type reflecting material die and preparation method thereof

A reflective material, micro-prism type technology, applied in metal material coating process, optics, optical components, etc., can solve the problems of reducing production cost, complex production process, reducing the complexity of production process, etc., to reduce manufacturing cost, reduce Production cost, the effect of reducing the complexity of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

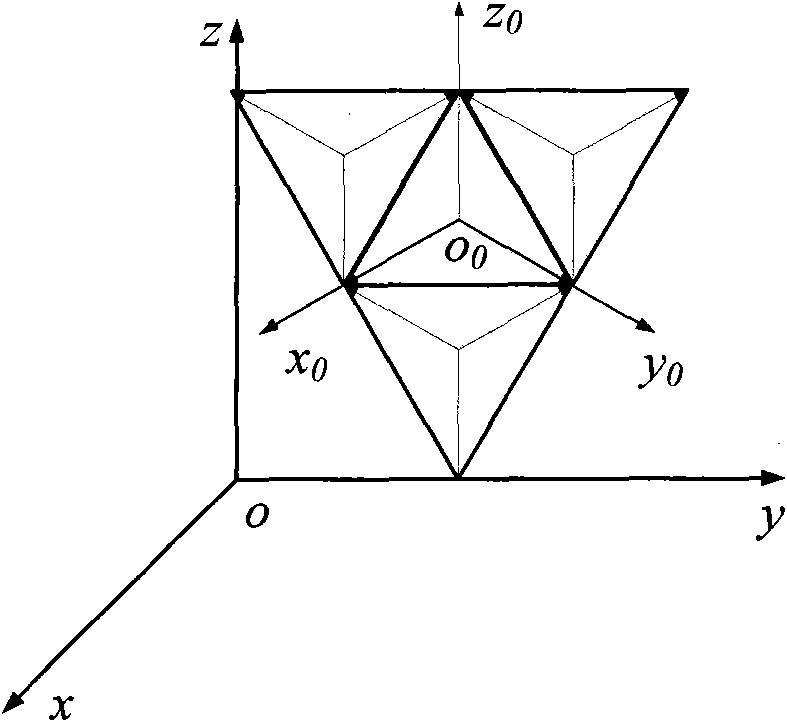

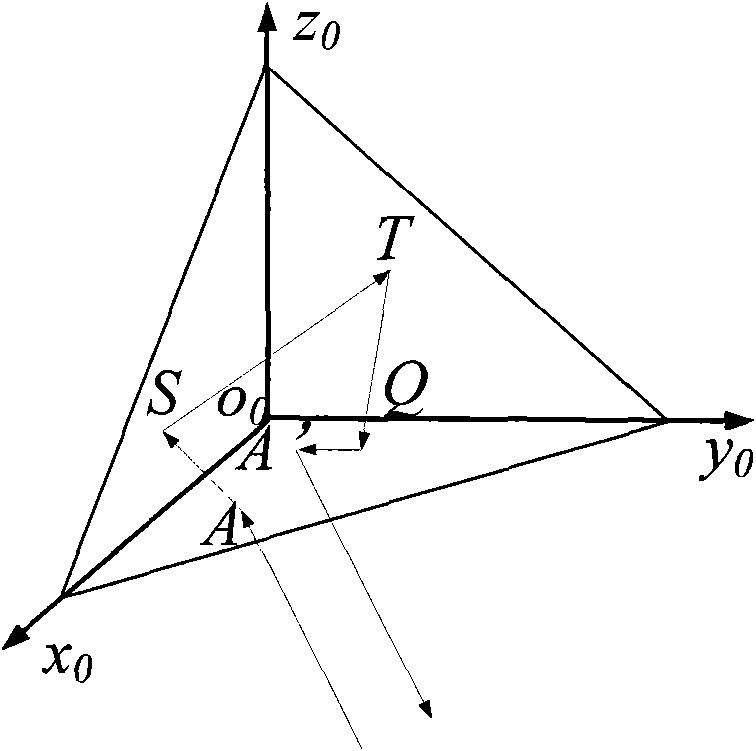

[0030] A large-scale microprism-type reflective material mold, including a mold substrate and a metal film coated on the mold substrate, the front of the mold substrate is pressed with a dense and evenly arranged concave prism array structure, and the mold substrate is coated The metal film is copper metal film and nickel metal film successively, and the mold substrate material is polycarbonate. The independent unit of the prism array structure is a regular triangular pyramid structure, the angle between the side surface and the bottom surface of the regular triangular pyramid is 19.47 degrees, and the side length of the bottom surface in the regular triangular pyramid structure is 120 microns.

[0031] The manufacturing process steps of a large-scale microprism type reflective material mold are as follows:

[0032] (A) The side length of the independent unit bottom surface of the prism array structure is set to 120 microns, according to the known technical methods of those skil...

Embodiment 2

[0041] The large-scale microprism type reflective material mold and production operation are the same as in Example 1, the difference is:

[0042] In step (D), a layer of copper metal film with a thickness of 250 nanometers is plated on the small-sized metal stencil processed in step (C). The coating method adopts electron beam evaporation, and the vacuum degree is 1×10 -3 Pa, through the calibration experiment, the coating rate is 1 nanometer per second, and the coating is finished after 250 seconds, and a copper metal film of 250 nm is obtained.

[0043] In the step (G), a copper metal film with a thickness of 250 nm is plated on the large-size template of the polycarbonate material made through the step (F), and the coating method is the same as that of the step (D).

[0044] All the other steps are the same as in Example 1.

Embodiment 3

[0046] The large-scale microprism type reflective material mold and production operation are the same as in Example 1, the difference is:

[0047] In step (D), a layer of copper metal film with a thickness of 100 nanometers is plated on the small-sized metal template processed in step (C). The coating method adopts electron beam evaporation, and the vacuum degree is 1×10 -3 Pa, through the calibration experiment, the coating rate is 1 nanometer per second, and the coating is finished after 100 seconds to obtain a 100 nanometer copper metal film.

[0048] In the step (G), a copper metal film with a thickness of 100 nm is plated on the large-size template of the polycarbonate material made through the step (F), and the coating method is the same as that of the step (D).

[0049] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com