Cable stripper

A stripper and cable technology, applied in the direction of dismantling/armored cable equipment, etc., can solve the problems of not being able to insert and strip, increase the amount of work, troublesome operation, etc., and achieve the effect of improving stripping efficiency and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

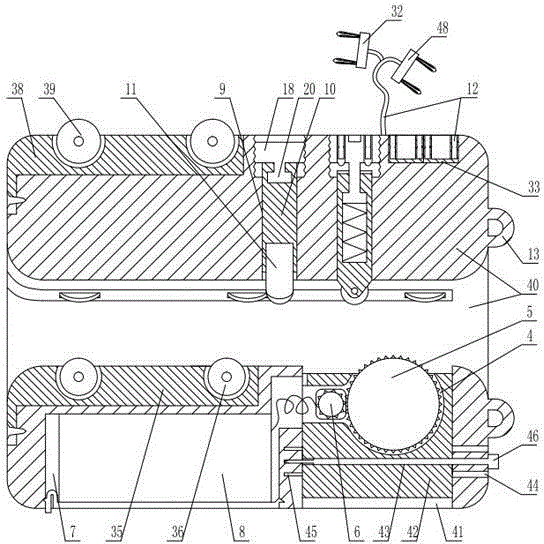

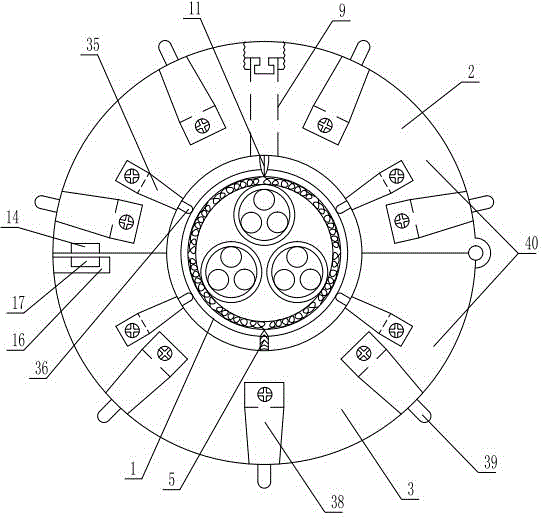

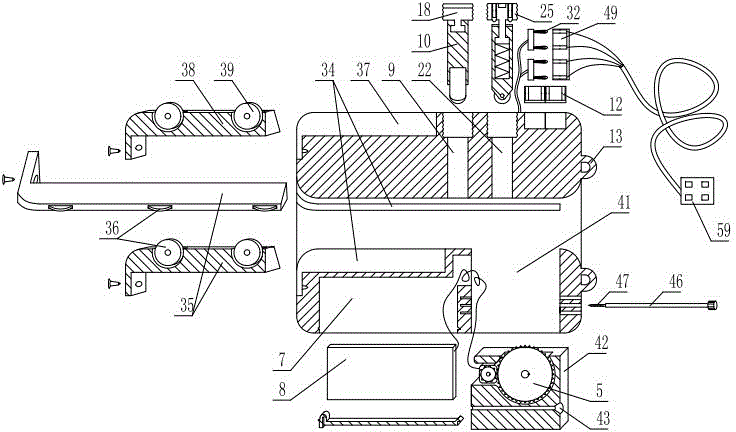

[0044] As shown in the figure, the cable stripper includes a sleeve 40 for covering the cable 1. The sleeve includes a main half pipe 2 and an auxiliary half pipe 3. One side of the main half pipe and the auxiliary half pipe are hinged together and the other side is locked by locking. The devices are locked together, and the side wall of the casing is provided with a power chamber 4 communicating with the inner cavity of the casing. The power chamber is installed with a power gear that is tightly fitted with the cable sheath and a motor 6 that drives the power gear 5 to rotate. A battery chamber 7 is provided, and a battery 8 for supplying power to the motor is installed in the battery chamber. A switch 12 for controlling the power supply of the motor is provided on the outer wall of the casing, and a blade chamber 9 is vertically arranged on the side wall of the casing. The cross section of the blade chamber It is a regular polygon, and the number of sides of the polygon is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com