Potato peeling machine

A potato and peeling machine technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of poor cleanliness, large peeling loss, rough surface of potatoes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

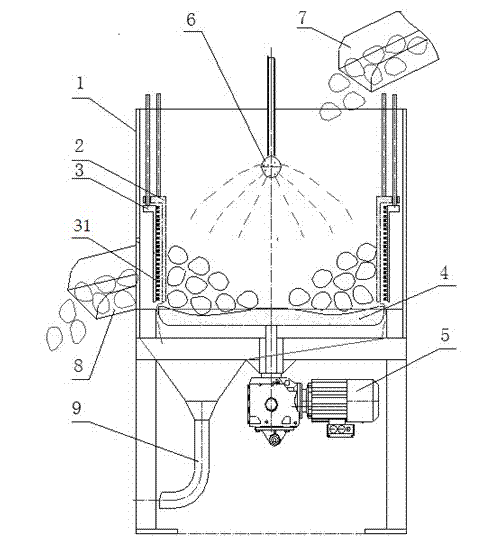

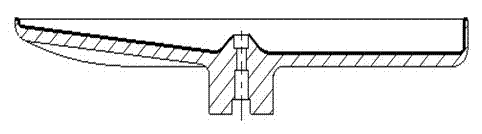

[0020] Such as figure 1 As shown, the potato peeling machine includes an outer cylinder 1, a first layer of working inner cylinder 2 that can be lifted and lowered without a cylinder bottom, a second layer of working inner cylinder 3 that can be lifted and lowered without a cylinder bottom, and the outer diameter is the same as the inner diameter of the outer cylinder 1. The matching rotatable disc 4, the second layer of working inner cylinder 3 is located inside the outer cylinder body 1, and a brush head 31 is provided on the inner surface of the second layer of working inner cylinder 3; the first layer of working inner cylinder 2 is located Inside the second layer of working inner cylinder 3, and the surface of the first layer of working inner cylinder 2 is a rough grinding surface, the inner surface of the first layer of working inner cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com